Blog & News

Check out the latest from MWES

Categories

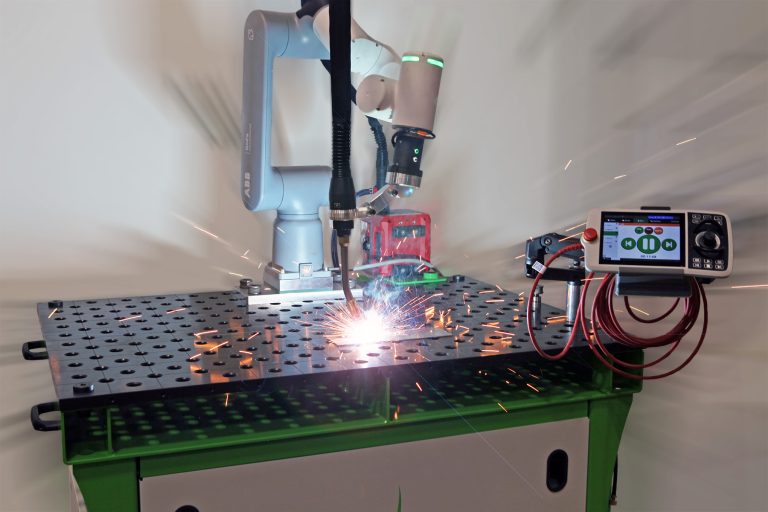

White Paper: Grow Your Process with Cobot Integration Amid Ongoing Labor Shortages

To solve labor the problems associated with the skilled labor shortage, MWES has developed several solutions that can augment and improve throughput.

What’s on Our Floor: OnRobot Grippers

In the automation world, many times it’s the gripper that packs the most innovation on a system. The grippers are where the automation system actually interacts with the products moving through the cell.

What’s on Our Floor: The FANUC CRX Cobot

A part of what we pride ourselves at Midwest Engineered Systems is keeping up to speed on the latest technologies in automation. With that in mind, we’ve brought in one of FANUC’s latest collaborative robots from the CRX series of industrial robots.

Next level machine tending with MWES’ standard tending cells

Our system was designed from the start to provide off-machine, secondary operations during the usual machine tending operations. That means if a part needs to be cleaned, deburred or repositioned back in the machine for more operations, our system can do it without the need for human help.

RIA Certified Robot Experts

Midwest Engineered Systems Inc. has the most RIA Certified Robotic Experts in the United States! Midwest Engineered Systems Inc., an innovative provider of premier custom machines and integrated systems, is proud to staff the most RIA (Robotic Industry Association) Certified Robot Experts in the United States. Midwest Engineered Systems received