Blog & News

Check out the latest from MWES

Categories

Automated Bag Making with Web Handling Systems

Midwest Engineered Systems provided a solution to a manufacturer of disposable plastic products that was seeking help with its large bag assembly operation. The customer struggled to keep up with production as demand was outpacing their throughput. We provided our customer with a new web handling machine capable of producing

The Role of Robotic Automation in Enhancing Military Equipment Manufacturing

Military equipment manufacturing requires precision, reliability and security. These are not just goals; they are imperatives. As our nation strives to equip our military forces with advanced technology, the role of robotic automation in the production process has become increasingly significant. Robotic automation is reshaping the landscape of military equipment

How MWES Safeguards Intellectual Property for the Defense Industry

In today’s rapidly evolving military and defense technology landscape, safeguarding intellectual property (IP) is crucial. Defense contractors and military equipment manufacturers constantly push the boundaries of what’s possible, developing cutting-edge solutions to address emerging threats and challenges. Midwest Engineered Systems, a trusted provider of factory automation integration solutions, understands the

The Evolution of Industrial Automated Control Systems

In the realm of industrial manufacturing, the rise of industrial automated control systems has been nothing short of revolutionary. These systems, which encompass a broad range of hardware and software, are designed to enhance automation efficiency, precision and reliability in various industrial processes. Without them, the automation we take for

Visit Us at the Converters Expo 2024

Members of the Midwest Engineered Systems web handling division will be attending this year’s Converters Expo at Lambeau Field in Green Bay, WI. The expo runs from April 17-18 and we will be at booth #425 in the Atrium. Once there you can speak with our experts on web handling and

Embracing Automation: Mitigating Risks in the Transition from a Manual to a Robotic Workforce

Global manufacturing stands on the brink of a transformative leap – the shift from a volatile manual labor workforce to a fully automated robotic process. This transition brings about increased efficiency, productivity and long-term cost savings. However, it does carry with it a host of risks that need to be

How Robotic Automation is Revolutionizing Medical Laboratories

As the recent pandemic showed the world, not properly running a cleanroom laboratory can not only endanger the lab workers but the greater world as a whole. Medical laboratories are essential for conducting scientific research, developing new drugs and diagnosing diseases. However, many of the tasks involved in these processes

MWES Receives Two Fanuc Integrator Sales Awards in 2023

Building upon their illustrious track record, Midwest Engineered Systems (MWES), a respected industry leader in the most innovative automation sector, is the latest recipient of the prestigious FANUC 2023 Authorized System Integrator Sales Award for both the 35+ units and the Growth Award. MWES’s 33 years of trusted experience are

AGVs vs AMRs: What’s the difference and which one is right for you?

If you are looking for a way to automate your material handling and transportation tasks, you might have come across two acronyms: AGV and AMR. But what do they mean and how do they differ? Midwest Engineered Systems has decades of experience integrating robots into manufacturing production lines. With that

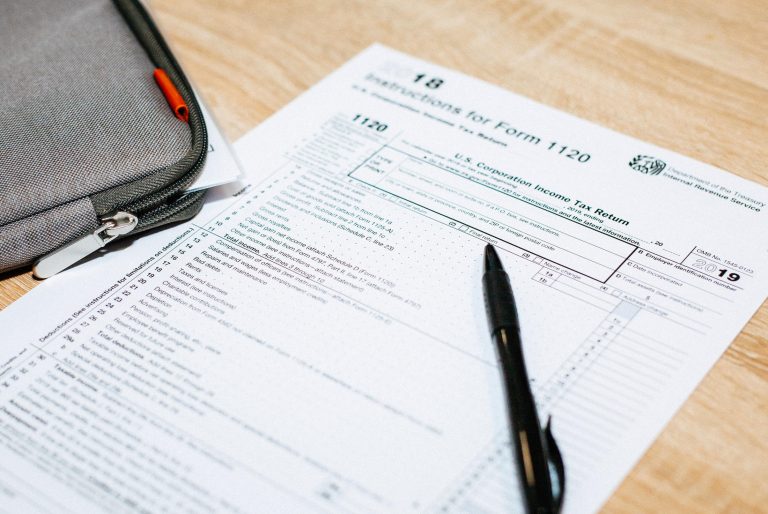

Get a Federal Tax Break on Automation Equipment with Section 179

If you are the owner of a small to medium-sized business looking for ways to reduce your tax liability and increase your productivity, you may want to consider investing in industrial robotic automation. Robotic automation in itself can help your business save time, money, and resources over time while improving