WHAT'S HAPPENING AT MWES

Blog & News

Check out the latest from MWES

Categories

Automated Assembly

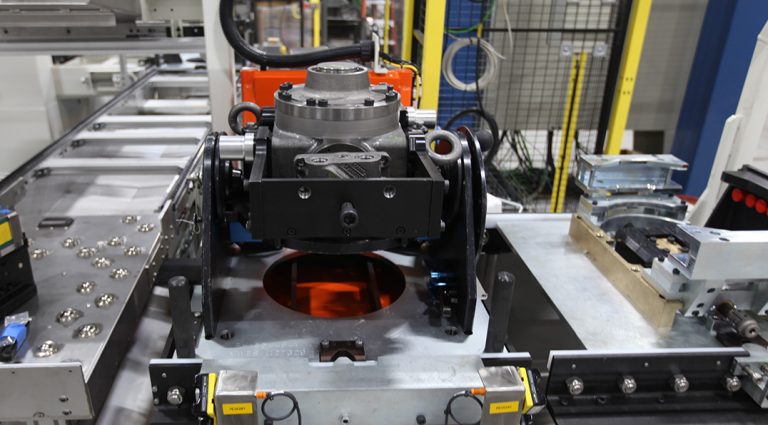

Project Spotlight: Hydraulic Motor Assembly Line

MWES designed a single manual production line for a firm that could manufacture over a dozen different variations of a hydraulic motor. The line utilizes a large number of sub-assembly stations, where workers perform the required tasks based on the specific variant of the motor being assembled.

October 21, 2021

12:27 pm

Automated Assembly

Project Spotlight: Trigger and Bottle Assembly Line

Midwest Engineered System built a fully automated assembly line that required no manual labor to perform the assembly operation. Robots using a vision system would pick and sort the multiple types of triggers as they travel on a single conveyor. On a separate conveyor, filled bottles would arrive at the bottle assembly station.

September 30, 2021

4:51 pm