Blog & News

Check out the latest from MWES

Categories

AGVs vs AMRs: What’s the difference and which one is right for you?

If you are looking for a way to automate your material handling and transportation tasks, you might have come across two acronyms: AGV and AMR. But what do they mean and how do they differ? Midwest Engineered Systems has decades of experience integrating robots into manufacturing production lines. With that

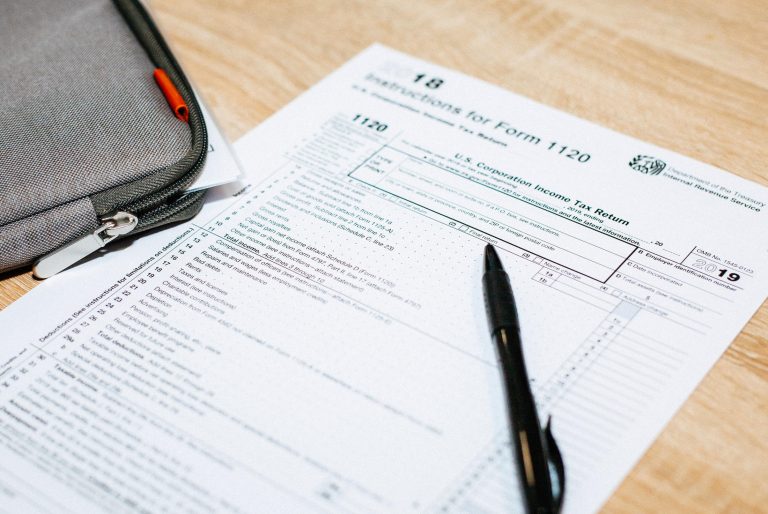

Get a Federal Tax Break on Automation Equipment with Section 179

If you are the owner of a small to medium-sized business looking for ways to reduce your tax liability and increase your productivity, you may want to consider investing in industrial robotic automation. Robotic automation in itself can help your business save time, money, and resources over time while improving

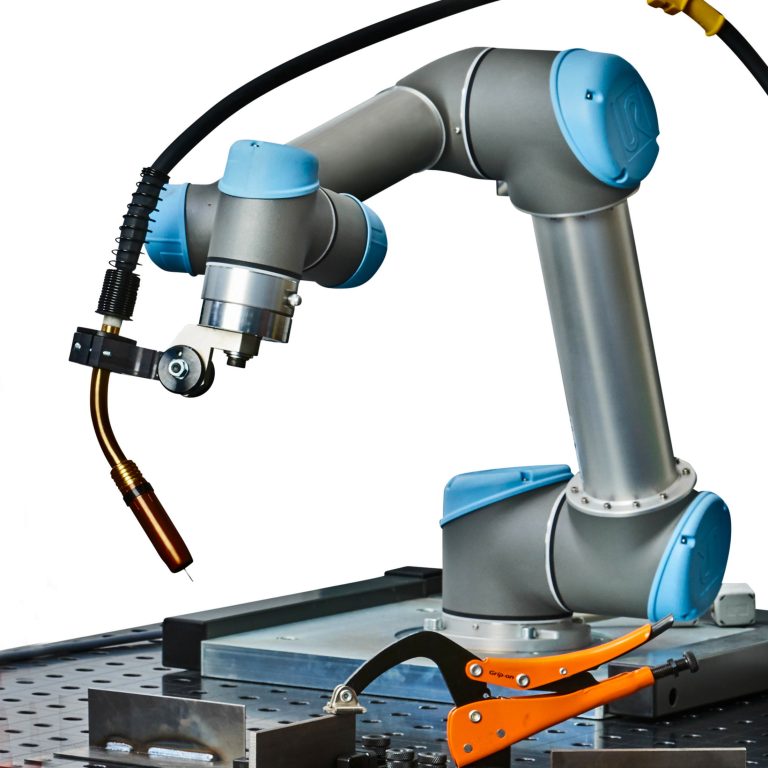

Cobots: The Innovative Solution to Labor Shortages

In today’s fast-paced industrial landscape, labor shortages have become a critical challenge for many businesses. The struggle to find and retain skilled workers has led companies to seek alternative solutions to maintain productivity and competitiveness. Enter collaborative robots, commonly known as cobots. These advanced robotic systems are not only addressing

Join us at the ICEC in Orlando

Midwest Engineered Systems will attend the 2024 International Converting Exhibition and Conference (ICEC) at the Orange County Convention Center in Orlando, Florida. This conference runs January 9-11 and we will be exhibiting at booth #1333. This conference is an amazing opportunity to speak with our web handling and converting experts.

How Lights-Out Manufacturing is the Future of Manufacturing

Lights-out manufacturing is not a fantasy, but a reality that is becoming more common in the manufacturing sector. It requires the support of various technologies, such as machine learning, cloud data, machine vision and robotics. These technologies allow machines to communicate with each other, monitor the production process and perform

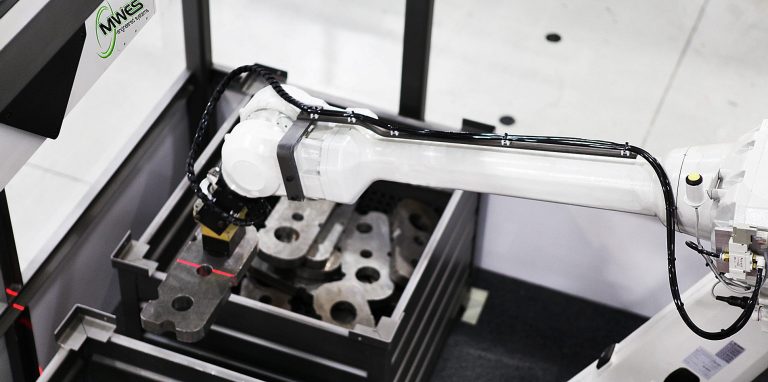

Factory Automation with Robotic Production Systems

Midwest Engineered Systems has spent decades improving our customers’ factory automation processes with robotic automation systems. By moving to robotic automation, those firms benefited from having a sizeable return on investment (ROI) and greatly improved throughput in their factory operations, all the while not being burdened by the labor shortages

Tips for Maintaining Your Industrial Robots

Just like all machines industrial robots require regular maintenance to keep running effectively and safely. The motors, electrical components, end-effectors and joints are vulnerable parts of a robot that can fail or lose effectiveness if not properly inspected and maintained. Underperforming robotic systems due to negligent maintenance can negatively affect

The Demographic Cliff: How AI and Automation are Filling the Gap

Baby boomers are reaching retirement age in large numbers, which means a significant portion of the workforce is leaving their jobs. This has led to concerns about a potential labor shortage, especially in industries that traditionally rely on skilled and experienced older workers, such as healthcare, manufacturing and skilled trades.

MWES is Ready for Industry 4.0

Industry 4.0 is used to describe the Fourth Industrial Revolution, which is characterized by the integration of digital technologies, such as artificial intelligence, cloud computing, big data, and the Internet of Things (IoT), into the manufacturing processes. One of the main benefits of the introduction of Industry 4.0 into robotics

Join Us at FABTECH 2023 in Chicago

FABTECH is North America’s largest metal forming, fabricating, welding and finishing event of the year! Midwest Engineered Systems Inc. will be exhibiting at this year’s FABTECH expo which runs September 11-14 in Chicago, IL at McCormick Place. At this year’s FABTECH we will be introducing our NEW MWES Easy-Arc TC300