In defense manufacturing, modifying fully built military equipment presents unique challenges. Systems often require upgrades, retrofits, or configuration changes after the initial assembly, and these processes must be executed with precision, speed, and security. Midwest Engineered Systems (MWES) provides custom automation solutions that streamline these modifications, improving accuracy, efficiency, and safety while protecting sensitive military assets.

The Challenge: Precision and Security in Military Equipment Modifications

Military OEMs and defense contractors face several obstacles:

- Complex, fully assembled systems that are difficult to rework manually

- High labor costs and limited skilled technicians for specialized modifications

- Strict quality and security requirements for every system

- Risk of human error in repetitive or intricate modification tasks

- Time-sensitive delivery schedules for critical defense programs

Manual modification processes can be slow, inconsistent, and labor-intensive, creating bottlenecks in military equipment readiness.

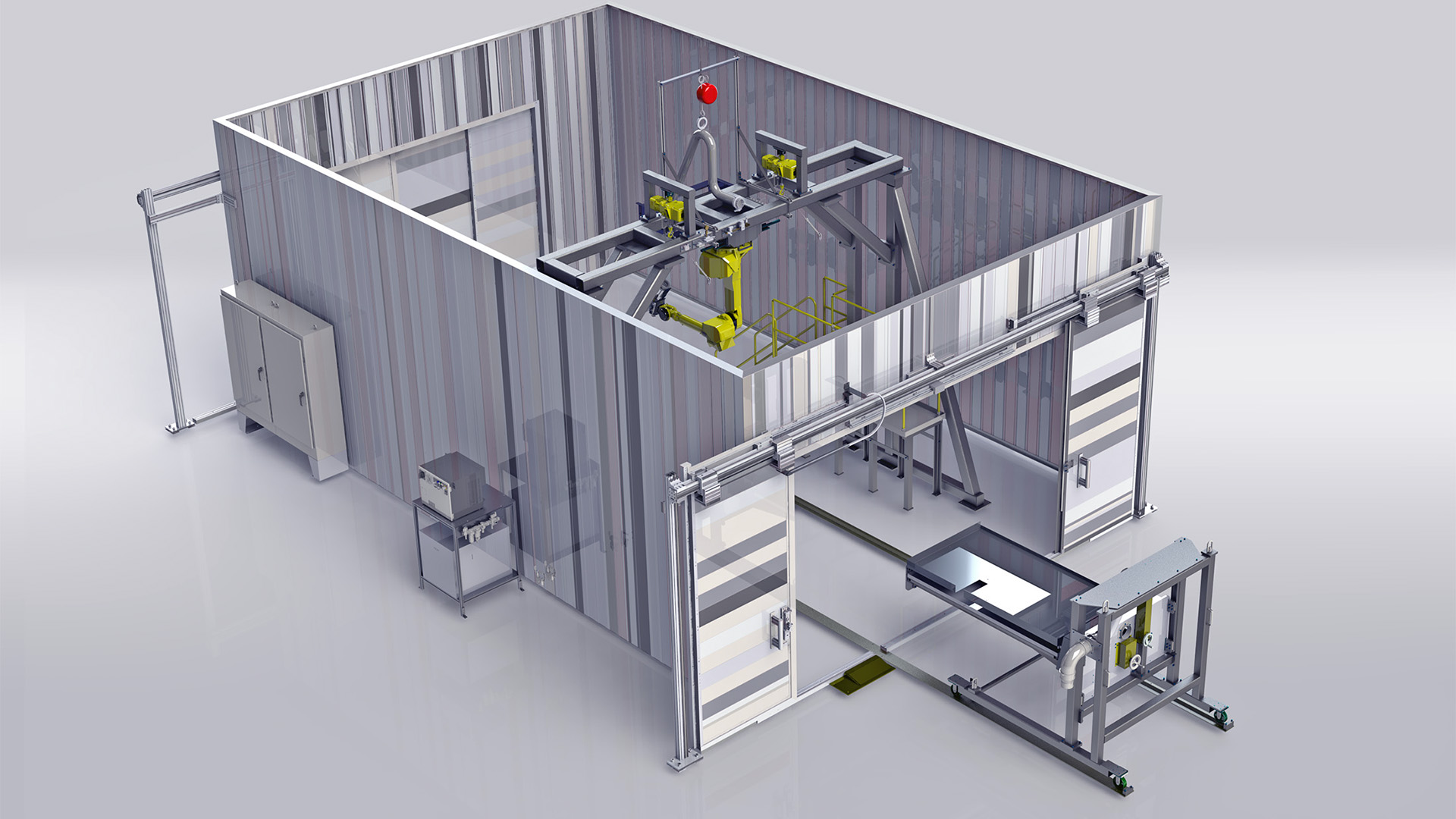

The MWES Solution: Automated Modifications for Military Systems

MWES engineers design custom robotic and automation systems that can:

- Retrofit and upgrade fully assembled equipment: Robots handle tasks such as drilling, fastening, welding, or component replacement without dismantling the entire system

- Ensure precise, repeatable modifications: Automation reduces human error and maintains strict tolerances required for military-grade equipment

- Integrate with existing production lines: Systems are engineered to work alongside existing processes for minimal downtime

- Enhance operator safety: Robots perform heavy, repetitive, or ergonomically challenging tasks

- Maintain IP and security compliance: All modifications occur within controlled, secure automation environments

These solutions allow defense manufacturers to upgrade and modify equipment faster, more accurately, and with fewer labor constraints.

Benefits of Automation in Military Equipment Modifications

- Increased Efficiency: Faster completion of complex modifications without compromising quality

- Improved Accuracy: Precise, repeatable processes ensure compliance with military specifications

- Labor Optimization: Skilled technicians can focus on high-value work instead of repetitive manual tasks

- Enhanced Safety: Reduces risk of injury during heavy or repetitive operations

- Secure and Controlled Operations: Automation safeguards sensitive designs and intellectual property

Applications

MWES automation solutions can be applied to a variety of military systems, including:

- Ground vehicles, aircraft, and naval equipment retrofits

- Weapon system upgrades and component replacements

- Custom tooling and modular attachments

- Electronics and assembly modifications within fully built systems

Each solution is custom-engineered to meet the unique demands of defense manufacturing and ensure reliable, repeatable outcomes.

Take Action: Upgrade Your Military Equipment Workflow

MWES partners with defense manufacturers to implement automated solutions that:

- Accelerate modifications and retrofits

- Reduce labor dependency and human error

- Ensure precision, safety, and security

Schedule a Consultation to explore how automation can streamline modifications to fully built military equipment, improve throughput, and safeguard sensitive assets.

Conclusion

By integrating custom automation solutions, MWES helps defense manufacturers retrofit, upgrade, and modify military equipment efficiently and securely. Automation ensures high-quality results, faster turnaround times, and safer operations, supporting mission-critical readiness and operational excellence.