Essential Tips for Maintaining Your Industrial Robots

Industrial robots are pivotal in modern manufacturing, offering precision, efficiency, and scalability. However, to ensure they operate at peak performance and longevity, regular maintenance is crucial. Neglecting upkeep can lead to unexpected downtimes, increased repair costs, and compromised safety.

1. Conduct Regular Visual Inspections

Routine visual checks help identify early signs of wear or potential issues. Focus on:

- Cables and connectors for signs of wear or damage.

- Robot arms and joints for any unusual wear patterns.

- End-effectors to ensure they are functioning correctly.

Early detection can prevent minor issues from escalating into major problems.

2. Implement Proper Lubrication Practices

Regular lubrication reduces friction, preventing premature wear and tear on moving parts. Ensure to:

- Grease joints and gears as per the manufacturer’s guidelines.

- Replace lubricants at recommended intervals to maintain optimal performance.

Proper lubrication not only extends the robot’s lifespan but also enhances its efficiency.

3. Maintain Cleanliness and Calibration

Dirt and debris can impair robot functionality. Regularly:

- Clean sensors, cameras, and scanners to ensure accurate data collection.

- Calibrate sensors and tools to maintain precision in operations.

A clean and well-calibrated robot ensures consistent and accurate performance.

4. Monitor Power Supply and Battery Health

A stable power supply is essential for uninterrupted operations. Regularly check:

- Battery voltage levels to prevent unexpected shutdowns.

- Power cables and connections for signs of wear or damage.

Ensuring a reliable power source minimizes the risk of downtime.

5. Stay Updated with Software and Firmware

Outdated software can lead to inefficiencies and vulnerabilities. Regularly:

- Update robot software and firmware to benefit from the latest features and security patches.

- Backup configurations before updates to prevent data loss.

Keeping software up-to-date ensures the robot operates with the latest enhancements.

6. Prioritize Safety Protocols

Safety is paramount when working with industrial robots. Always:

- Follow ISO 10218 safety standards to ensure safe robot operations.

- Implement safety barriers and interlocks to protect personnel.

- Provide regular safety training for operators and maintenance staff.

Adhering to safety protocols reduces the risk of accidents and injuries.

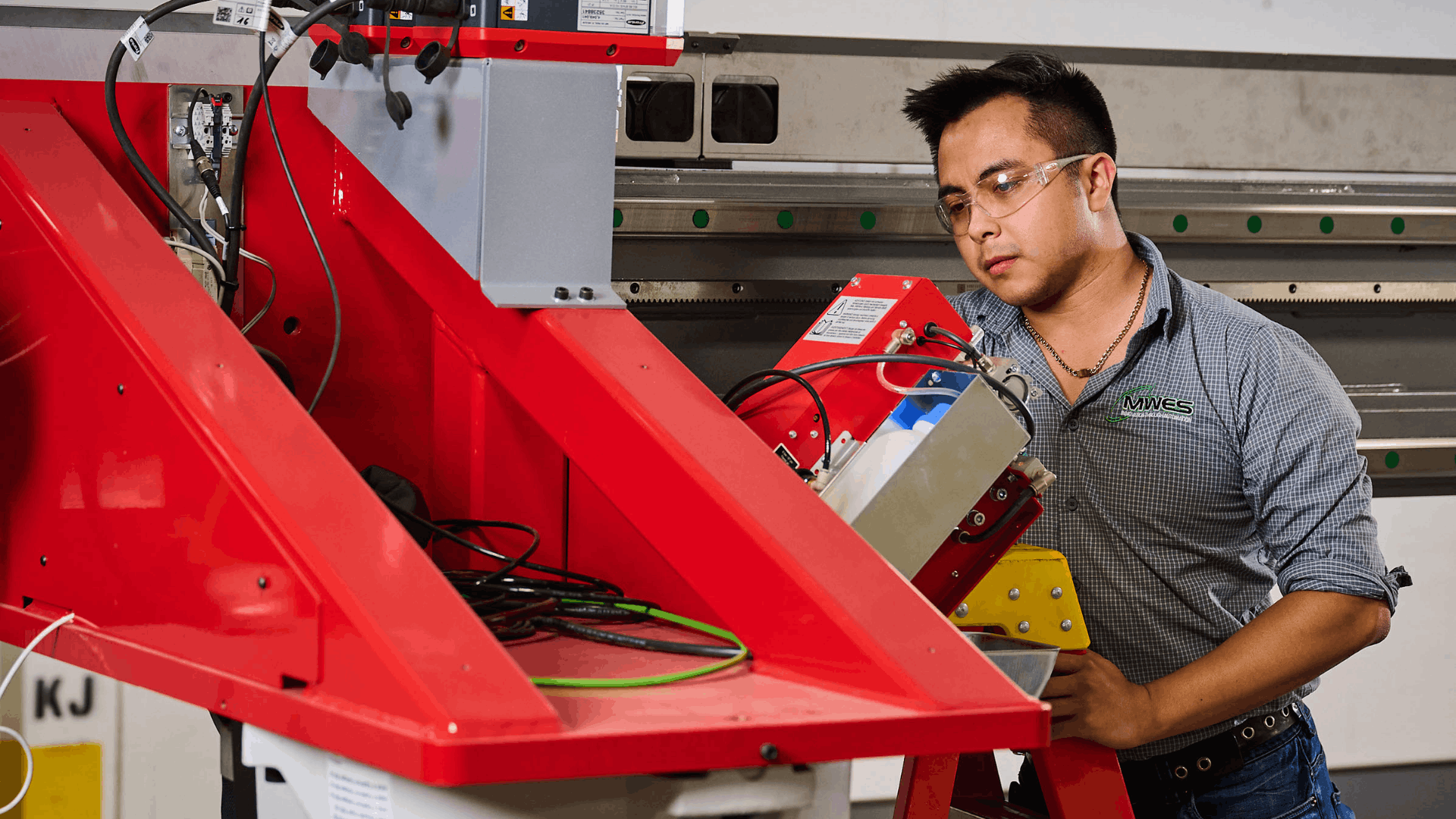

Why Choose MWES for Your Robotic Maintenance Needs?

At MWES, we specialize in providing comprehensive robotic maintenance solutions tailored to your specific needs. Our services include:

- Routine Maintenance Plans: Customized schedules to keep your robots in optimal condition.

- Emergency Support: Rapid response to minimize downtime during unexpected issues.

- Training Programs: Empowering your team with the knowledge to perform basic maintenance tasks.

Partnering with MWES ensures your robotic systems operate efficiently, safely, and reliably.

Ready to Enhance Your Robot’s Performance?

Don’t wait for issues to arise. Contact MWES today to discuss how our robotic maintenance services can benefit your operations.