In today’s competitive manufacturing landscape, maximizing the value of your existing automation systems is crucial. Midwest Engineered Systems (MWES) helps manufacturers enhance, upgrade, and expand their current robotic and automated systems to boost productivity, reduce downtime, and adapt to evolving production demands.

Why Expand Your Existing Automation?

Many manufacturers invest heavily in automation but underutilize their systems due to limited capabilities, outdated technology, or evolving production needs. Expanding existing automation offers:

- Increased throughput: Add new robotic stations or conveyors to handle higher volumes

- Enhanced flexibility: Integrate additional tasks like assembly, inspection, or packaging

- Cost savings: Upgrade and expand existing systems rather than replacing them entirely

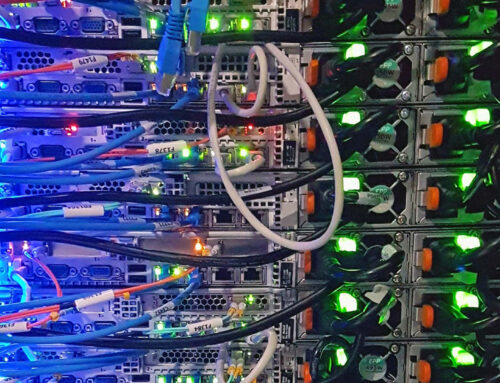

- Reduced downtime: Modernize control systems, sensors, and software for smoother operations

- Future-proofing: Prepare systems for Industry 4.0 integration and advanced robotics

With the right upgrades, your current automation investment continues to deliver ROI while meeting new production goals.

How MWES Expands Your Automation

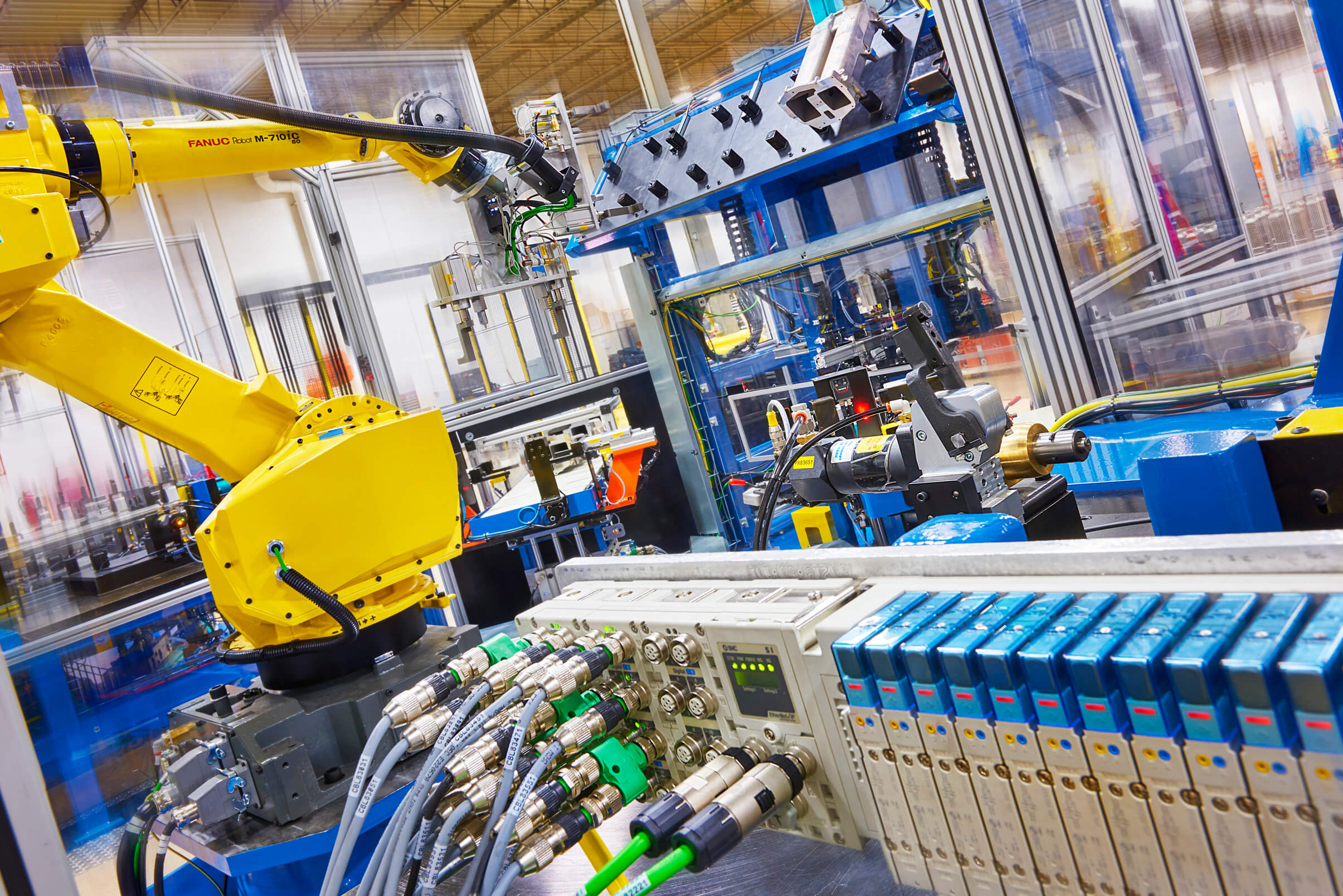

MWES specializes in custom automation solutions designed to seamlessly integrate with existing equipment. Our approach includes:

- System Evaluation: Assess current automation systems for performance, capacity, and upgrade potential

- Process Optimization: Identify bottlenecks and opportunities to add efficiency through additional automation

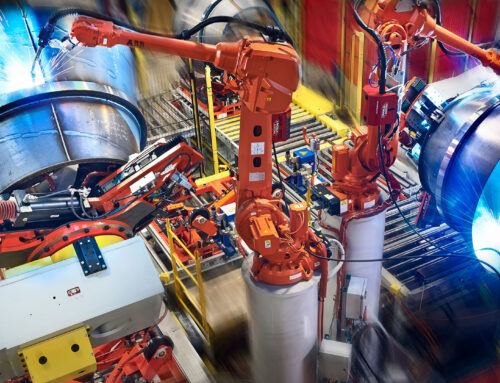

- Robotic Integration: Expand your system with industrial robots, collaborative robots (cobots), or material handling automation

- Control System Upgrades: Modernize PLCs, HMIs, and networked controls for better connectivity and reliability

- End-of-Arm Tooling (EOAT) Solutions: Tailored grippers, weld heads, and tooling for new production tasks

- Seamless Installation: MWES engineers handle integration, testing, and commissioning, ensuring minimal disruption

By combining evaluation, modernization, and integration, MWES maximizes the potential of your existing automation systems while minimizing the learning curve for operators.

Benefits of Expanding Existing Automation

- Faster Production: Add capacity without building entirely new systems

- Lower Capital Costs: Extend the life and value of your current automation investment

- Improved Product Quality: Upgrade sensors, vision systems, and robotic precision

- Flexibility for Multiple Products: Easily switch between product lines or tasks

- Scalability: Prepare for future expansion without major redesigns

Real-World Impact

Manufacturers working with MWES have experienced:

- A 30–50% increase in throughput by adding new robotic stations

- Reduced labor requirements through expanded automated material handling

- Improved workflow efficiency with optimized conveyor and robotic integration

- Enhanced production quality with upgraded controls and inspection systems

Take Action: Upgrade Without Replacing

Your existing automation system is already an asset—make it work even harder for you. MWES helps manufacturers:

- Evaluate current automation capabilities

- Identify opportunities for expansion or upgrades

- Integrate new automation technologies with minimal downtime

- Ensure scalability and long-term performance

Schedule a Consultation Today to discover how MWES can expand your existing automation and unlock new production potential.

Conclusion

Upgrading and expanding your current automation systems is a smart, cost-effective strategy to keep pace with evolving manufacturing demands. MWES combines custom automation expertise, robotic integration, and process optimization to ensure your systems deliver maximum productivity, efficiency, and ROI.