Robotic End Effectors & EOAT: The Hands That Power Automation

Industrial robots are transforming modern manufacturing—but a robot arm alone cannot perform work without the right tool. That’s where robotic end effectors, also known as End-of-Arm Tooling (EOAT), play a critical role. EOAT enables robots to grip, move, assemble, weld, inspect, and process parts with precision, speed, and consistency.

At MWES, end effectors are engineered as an integral part of every robotic automation system. Selecting and designing the right EOAT solution is essential to achieving reliable performance, repeatable quality, and long-term return on investment.

What Is EOAT (End-of-Arm Tooling)?

EOAT refers to any tool or device mounted to the end of a robotic arm that allows it to interact with parts, products, or its environment. Often described as the “hands” of a robot, end effectors define what a robotic system can actually do.

Without properly designed EOAT, even the most advanced industrial robot cannot perform meaningful work. Effective end-of-arm tooling enables robots to:

- Grasp and manipulate parts

- Perform assembly or fastening operations

- Weld, grind, or finish components

- Dispense materials such as adhesives or sealants

- Inspect parts using vision or sensing technologies

Because every application is different, EOAT must be carefully matched to part geometry, weight, surface condition, cycle time, and production variability.

Common Types of Robotic End Effectors

Robotic Grippers

Grippers are the most widely used EOAT solution. They allow robots to securely grasp parts for material handling, assembly, palletizing, and machine tending. Grippers may be pneumatic, electric, or servo-driven and are available in parallel, angular, three-finger, or adaptive designs.

Gripper used to move medical vials

Gripped used to move pieces between grinder and inspection

Vacuum End Effectors

Vacuum EOAT uses suction cups or foam tooling to lift flat, lightweight, or porous materials. These systems are common in packaging automation, palletizing, sheet handling, and logistics applications where speed and flexibility are essential.

Process End Effectors

Process tools perform an action on the part rather than simply handling it. These EOAT solutions include welding torches, dispensing heads, cutting tools, sanding and grinding spindles, and finishing tools—critical for robotic welding, material removal, and /capabilities/automation-systems/surface-treating/surface treatment applications.

Laser Welding EOATs

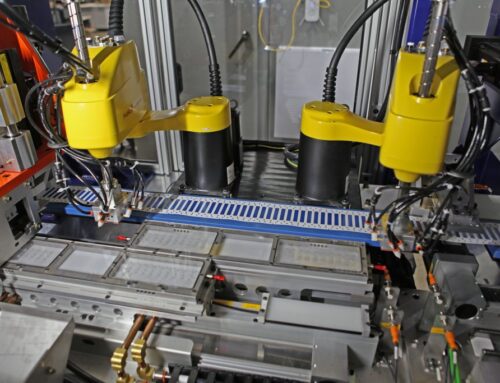

Inspection & Vision EOAT

Vision-guided end effectors integrate cameras, laser scanners, or sensors to inspect part quality, verify orientation, or guide robotic motion. These EOAT systems support automated inspection, quality assurance, and adaptive robotic processes.

Why EOAT Design Matters in Robotic Automation

The performance of a robotic automation system is directly tied to the quality of its end-of-arm tooling. Poorly designed EOAT can limit speed, reduce accuracy, increase downtime, and create safety risks.

Well-engineered EOAT delivers:

- Higher throughput and faster cycle times

- Consistent, repeatable part handling

- Reduced scrap and rework

- Improved workplace safety and ergonomics

- Greater flexibility for product changeovers

At MWES, EOAT is never treated as an afterthought. Our engineering team evaluates the full process—before, during, and after the robotic operation—to ensure the end effector supports long-term reliability and scalability.

Custom EOAT & Tool Changers for Maximum Flexibility

While off-the-shelf end effectors work for some applications, many automation challenges require custom EOAT solutions. MWES designs and builds custom end-of-arm tooling to address complex geometries, variable parts, tight tolerances, or multi-function requirements.

EOAT can also be paired with automatic tool changers, allowing a single robot to switch between multiple tools—such as grippers, inspection devices, or process tools—without manual intervention. This capability increases system flexibility and maximizes robot utilization.

EOAT Across Real-World Applications

MWES integrates robotic end effectors and EOAT across a wide range of automation systems, including:

- Material handling and palletizing

- Robotic welding and fabrication

- Assembly and machine tending

- Packaging and case handling

- Inspection, vision, and quality verification

By combining deep automation expertise with application-specific EOAT design, MWES delivers robotic systems that perform reliably in real-world manufacturing environments.

Unlock Automation Performance with the Right EOAT

In robotics, the end effector is where automation meets reality. The right EOAT transforms robotic motion into productivity, quality, and measurable results.

Whether you need standard grippers, vacuum tooling, custom end-of-arm tooling, or advanced inspection EOAT, MWES designs and integrates solutions engineered around your process—not the other way around.

Explore MWES robotic automation systems and learn how the right EOAT can elevate your production performance.