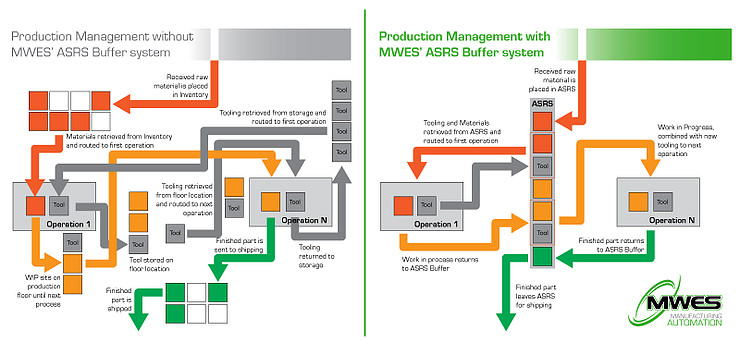

Maintaining consistent production flow across automated processes is a constant challenge for manufacturers. To address this, Midwest Engineered Systems has developed a new AS/RS buffer system that enhances throughput, improves material handling efficiency, and supports smarter production synchronization.

In modern manufacturing environments, AS/RS buffer systems play a critical role in balancing upstream and downstream operations. By intelligently staging and sequencing parts, buffers help eliminate bottlenecks caused by mismatched cycle times, equipment downtime, or process variability. The MWES AS/RS buffer system was engineered specifically to provide this flexibility while maintaining high levels of reliability and control.

Improving Flow with Intelligent Buffering

The MWES AS/RS buffer system enables manufacturers to decouple processes without sacrificing efficiency. By creating a controlled buffer between operations, the system helps maintain steady production flow even when individual machines or workcells operate asynchronously.

Key benefits include:

- Improved throughput by keeping downstream processes supplied with parts

- Reduced line stoppages caused by imbalanced cycle times

- Greater flexibility for high-mix, low-volume production environments

- Enhanced material flow visibility through integrated controls and software

This approach is especially valuable in complex manufacturing operations such as automated assembly, packaging, welding, and web handling, where uninterrupted flow is critical to overall equipment effectiveness (OEE).

Designed for Seamless Integration

The AS/RS buffer system is engineered to integrate seamlessly with existing automation infrastructure, including conveyors, robotic workcells, and material handling equipment. MWES designs each buffer solution to fit the customer’s specific layout, part characteristics, and production requirements—ensuring smooth communication and reliable operation across the entire system.

With real-time tracking and intelligent queue management, the system provides manufacturers with greater control over work-in-process inventory while supporting consistent, predictable output.

A Scalable Solution for Modern Manufacturing

As production demands evolve, flexibility becomes essential. MWES AS/RS buffer systems are designed with scalability in mind, allowing manufacturers to expand capacity, add stations, or adapt workflows without major disruption. This future-ready approach supports long-term growth while protecting automation investments.

Part of a Broader Automation Strategy

The AS/RS buffer system is one of many automation solutions delivered by MWES to help manufacturers optimize operations. With decades of experience in automation system integration, MWES combines material handling, robotics, controls, and software into cohesive solutions that improve efficiency, reliability, and ROI.

Manufacturers interested in learning how AS/RS buffering can improve production flow and reduce bottlenecks are encouraged to connect with the MWES team to discuss application-specific requirements.