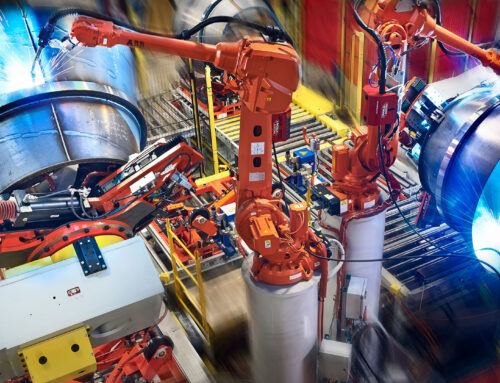

In modern manufacturing, precision, speed, and reliability are critical. Cartesian, gantry, and rectilinear robots provide manufacturers with highly accurate, repeatable automation solutions for material handling, assembly, and production tasks. Midwest Engineered Systems (MWES) specializes in designing and integrating these systems to maximize efficiency, reduce labor dependency, and improve product quality.

Understanding Cartesian, Gantry, and Rectilinear Robots

These robot types are often used interchangeably in industrial automation but have unique characteristics:

- Cartesian Robots: Move along the X, Y, and Z axes in a straight line. Ideal for pick-and-place tasks, assembly, and packaging.

- Gantry Robots: Large-scale Cartesian systems that span a work area. Commonly used for heavy payload handling and large-part assembly.

- Rectilinear Robots: Focused on linear motion in one or more axes, typically used in precision cutting, welding, or material transport.

All three types offer high repeatability, scalable performance, and easy integration into existing production lines.

The Challenge: Manual Processes Slowing Your Production

Many operations still rely on:

- Labor-intensive pick-and-place tasks

- Inconsistent assembly processes

- Limited throughput due to human handling

- High operational costs and inefficiencies

These challenges lead to production delays, quality variability, and increased labor dependency, limiting growth potential

MWES Solutions: Custom Cartesian & Gantry Automation

MWES designs and integrates custom robotic systems to:

- Automate repetitive tasks: Reduce manual labor and improve consistency

- Increase precision: Linear motion ensures repeatable, accurate operations

- Expand scalability: Gantry robots can cover large work areas for multiple stations

- Improve throughput: Speed up pick-and-place, assembly, and material handling processes

- Enhance flexibility: Systems can be reprogrammed or reconfigured for evolving production needs

By integrating Cartesian, gantry, or rectilinear robots, manufacturers can achieve higher productivity, lower costs, and superior quality.

Benefits of Cartesian, Gantry, and Rectilinear Robots

- High Precision and Repeatability: Minimize errors and maintain consistent quality

- Increased Production Efficiency: Robots perform repetitive tasks faster and more reliably than humans

- Enhanced Safety: Automates heavy, hazardous, or ergonomically challenging tasks

- Reduced Labor Dependency: Free up staff for higher-value work

- Flexible and Scalable: Systems can be adapted as production needs grow

Take Action: Maximize Your Manufacturing Potential

MWES partners with manufacturers to design, integrate, and support Cartesian, gantry, and rectilinear robot systems that:

- Improve throughput and production efficiency

- Reduce human error and enhance product quality

- Automate repetitive or hazardous tasks

- Provide scalable solutions for future growth

Schedule a Consultation today to see how MWES automation solutions can optimize your manufacturing operations and unlock your facility’s full potential.

Conclusion