Efficient, flexible, and reliable material handling is essential for today’s manufacturers. End-of-arm tools (EOAT) provide a versatile solution for pick-and-place, assembly, and machine tending applications, helping manufacturers boost productivity, reduce labor costs, and improve process consistency. At Midwest Engineered Systems (MWES), we integrate EOAT into custom robotic automation systems designed to meet your production needs..

What Are End-of-Arm Tools (EOAT)?

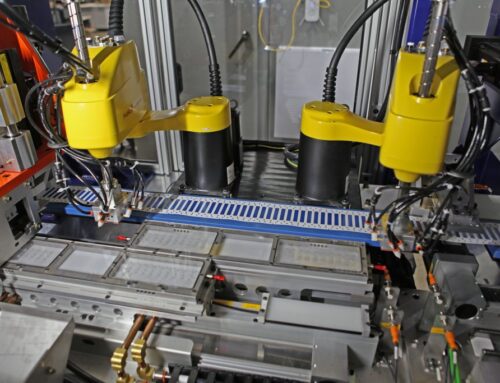

EOAT are advanced tools mounted on robotic arms that grip, hold, and manipulate parts safely and efficiently. Key types include:

- Electric Grippers: Provide adjustable gripping force for precision pick-and-place and assembly operations.

- Vacuum Grippers: Handle delicate, irregular, or lightweight products without causing damage.

- Collaborative Grippers: Engineered for safe human-robot collaboration, ideal for cobot applications.

- Adaptive Grippers: Automatically conform to part geometry, making them perfect for mixed-product production lines.

These EOAT are easy to integrate and configurable for fast changeovers, providing flexible deployment across multiple applications—perfect for manufacturers facing high-mix, low-volume production challenges.

The Challenge: Manual Handling Slowing Production

Manufacturers relying on manual handling often face:

- Inconsistent part placement, leading to defects or damage

- High labor costs for repetitive pick-and-place tasks

- Safety risks when moving heavy, sharp, or awkward components

- Production bottlenecks caused by slow manual processes

These challenges limit throughput, product quality, and operational efficiency, making EOAT automation solutions a strategic investment.

The MWES Solution: Custom Robotic Systems with EOAT

MWES designs custom robotic automation systems that leverage EOAT to:

- Automate repetitive tasks, reducing reliance on manual labor

- Increase precision, ensuring repeatable, accurate part handling

- Provide flexibility, accommodating diverse part sizes and geometries

- Boost throughput, minimizing cycle times and maximizing production capacity

- Enhance safety, reducing operator exposure to hazardous or heavy materials

Our engineers evaluate your workflow to select and integrate the right EOAT for your system, ensuring seamless operation and a fast return on investment.

Benefits of EOAT

- Higher Productivity: Automate labor-intensive handling across multiple stations

- Improved Part Quality: Reduce defects caused by inconsistent manual handling

- Labor Savings: Free operators from repetitive and physically demanding tasks

- Flexibility & Adaptability: Handle varied part geometries without extensive retooling

- Enhanced Safety: Reduce risk by letting robots handle heavy or hazardous components

Industries That Benefit

MWES EOAT solutions are ideal for:

- Electronics Assembly: Precision handling of small, delicate components

- Medical & Pharmaceutical Manufacturing: Safe, hygienic handling of sensitive products

- Automotive & Heavy Machinery: Efficient movement of large or irregular parts

- Food & Beverage Packaging: Consistent, hygienic handling for diverse products

- Industrial Equipment Fabrication: Streamlined material handling for high-volume production

Take Action: Optimize Your Material Handling

MWES partners with manufacturers to design, integrate, and deploy EOAT within custom robotic systems that:

- Automate repetitive and labor-intensive tasks

- Increase handling precision and reduce part damage

- Improve throughput and operational efficiency

- Provide flexible, scalable solutions for future production needs

Schedule a Consultation to see how EOAT and MWES automation expertise can transform your material handling operations and maximize ROI.

Conclusion

EOAT deliver precision, flexibility, and efficiency for modern manufacturing operations. By partnering with MWES, manufacturers can optimize workflows, enhance safety, and scale production, turning labor-intensive tasks into reliable, automated processes.