The Challenge

Outdated Controls Causing Poor Tension Management and Reliability

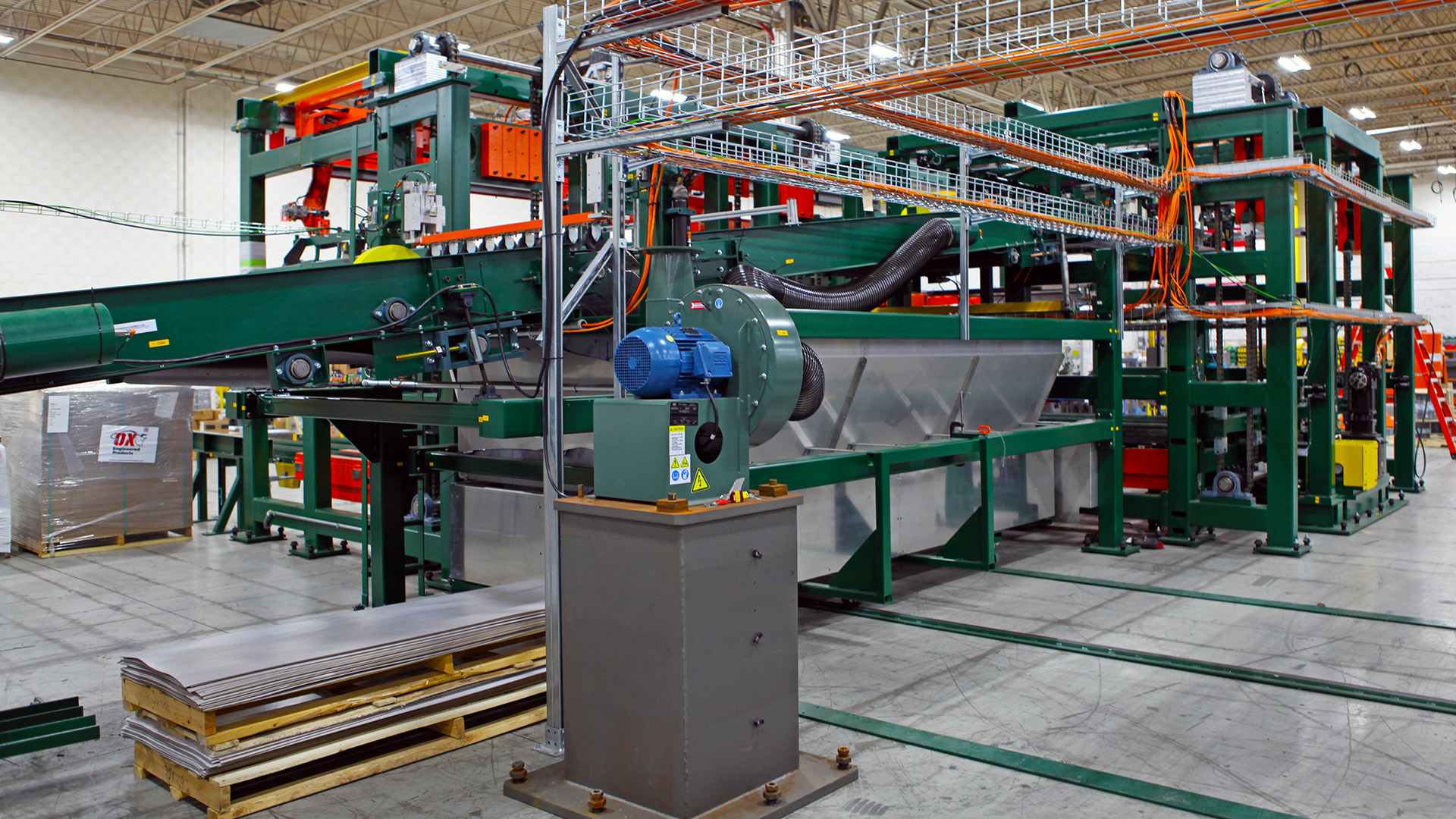

Their existing system relied on obsolete Eurotherm AC drives and standalone temperature controllers. The line lacked modern safety integration and risked unplanned downtime. Upgrading was essential to:

- Replace aging drives with current, maintainable technology

- Integrate control of oven temperature zones and line speed

- Enhance safety through modern interlocks and PLC-controlled e-stop systems

- Maintain uptime and improve process consistency without full replacement

MWES was selected to perform a full retrofit to modernize drive systems and controls while minimizing downtime and capital expense.

The Solution

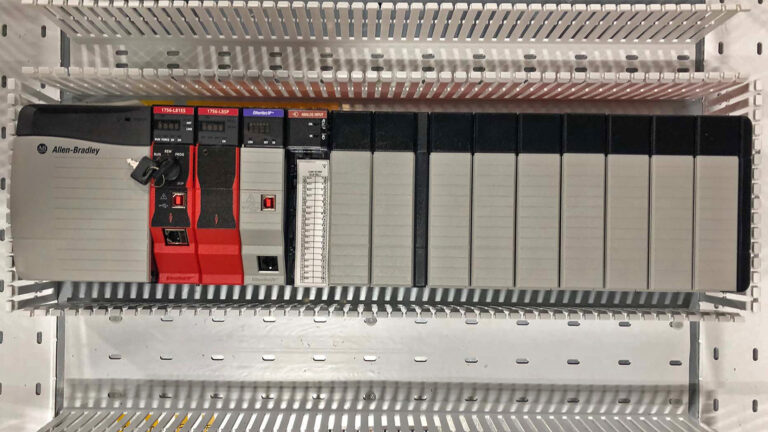

Allen-Bradley & Siemens Drives Safety PLC Upgrade with New Control Cabinets

MWES delivered a complete controls modernization including:

- Replacement of legacy Eurotherm AC drive systems with Siemens S120 and G120 variable-speed drives

- Installation of new machine-area control cabinets and air conditioning units for drive cooling

- Integration of an Allen-Bradley ControlLogix GuardLogix Safety PLC, also assuming multi-zone oven temperature control

- Wiring replacement for all safety devices, e-stops, and interlocks

- New guarding, safety pushbuttons, bump strips, and operator interface mapping

This retrofit modernized the entire drive and control ecosystem, allowing coordinated motion and temperature control while improving operator safety and diagnostics.

The Results

Rebuilt Reliability, Enhanced Safety, and Extended Service Life

The mechanical upgrade delivered tangible benefits:

- Restored line reliability with supportable, field-tested drive technology

- Integrated safety system minimised operator risk and aligned with modern standards

- Temperature and motion controls consolidated into a single, programmable system

- Extended useful life of the existing web line at a fraction of a total rebuild cost

By transitioning to modern drives and PLC control, MWES helped the customer preserve a proven system while improving safety, reliability, and maintainability for years to come.