In modern manufacturing and warehousing, pallet quality is critical. Defective pallets can lead to product damage, worker injuries, and operational delays, making quality inspection an essential step in any material handling process. Midwest Engineered Systems (MWES) provides custom automation solutions that improve pallet inspection, enhance efficiency, and ensure the safety and reliability of your operations.

The Importance of Pallet Quality

Pallets are more than just a platform for transporting goods—they are a key component of the supply chain infrastructure. Poor-quality pallets can result in:

- Damaged products due to uneven surfaces, broken boards, or nails

- Safety hazards for warehouse staff during lifting, stacking, or transport

- Downtime and operational inefficiency when pallets fail during automated handling

- Increased costs from rejected shipments or replacement pallets

Ensuring pallet quality protects both products and people, while maintaining smooth and uninterrupted workflows.

Automation in Pallet Quality Inspection

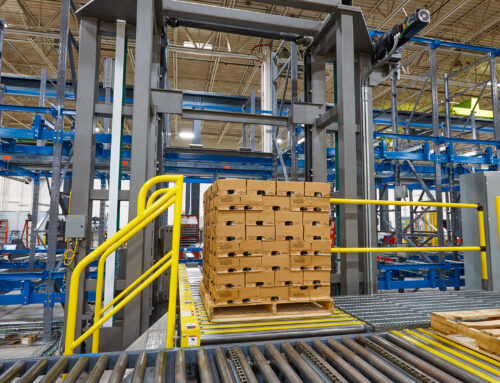

Traditional pallet inspection is manual, slow, and prone to human error. MWES integrates robotic and automated systems to enhance inspection processes:

- Vision Systems: Cameras and sensors detect cracks, splits, warping, and other defects in real time

- Automated Scanning: High-speed conveyors move pallets through inspection stations for consistent and accurate analysis

- Data Logging & Reporting: Every pallet is tracked, and defects are recorded for quality management and traceability

- Integration with Material Handling: Inspected pallets can be automatically sorted, routed, or rejected, minimizing manual handling

Automation not only improves accuracy, but also reduces labor costs and increases throughput, helping your operation run more efficiently.

Benefits of MWES Pallet Inspection Solutions

- Higher Safety Standards: Prevent injuries by removing defective pallets from circulation

- Improved Product Protection: Reduce damage to goods during storage and transport

- Consistent Quality Control: Eliminate human error with repeatable automated inspection

- Operational Efficiency: Speed up inspection and integrate seamlessly with existing material handling systems

- Data-Driven Insights: Track trends, identify recurring issues, and make informed decisions for pallet procurement

MWES: Your Partner in Automated Pallet Inspection

MWES designs custom pallet inspection systems that fit your warehouse or production facility’s unique needs. Our solutions combine robotics, vision technology, and conveyor automation to deliver:

- Automated detection of pallet defects

- Real-time monitoring for quality assurance

- Seamless integration with existing conveyors, sorters, and warehouse systems

- Scalable solutions for high-volume operations

Whether your facility handles food and beverage, medical, consumer goods, or industrial products, MWES ensures your pallets meet the highest quality and safety standards.

Take Action: Automate Your Pallet Quality Inspection

Don’t let defective pallets slow down your operations or compromise safety. MWES can help you implement advanced automated pallet inspection solutions that improve efficiency and protect your products and staff.

- Schedule a Consultation

- Discover custom pallet inspection systems for your operation

- Learn how automation can increase throughput and reduce costs

Conclusion

Automated pallet inspection is a critical step for modern warehouses and manufacturing facilities. With MWES, you can ensure safety, efficiency, and consistent quality in your material handling processes, while leveraging automation to optimize your operations.