In today’s high-speed manufacturing environment, efficient web handling is critical to keeping production lines running smoothly. Midwest Engineered Systems (MWES) recently helped a customer double their productivity with custom web handling equipment designed to improve material flow, reduce waste, and minimize downtime.

What is Web Handling?

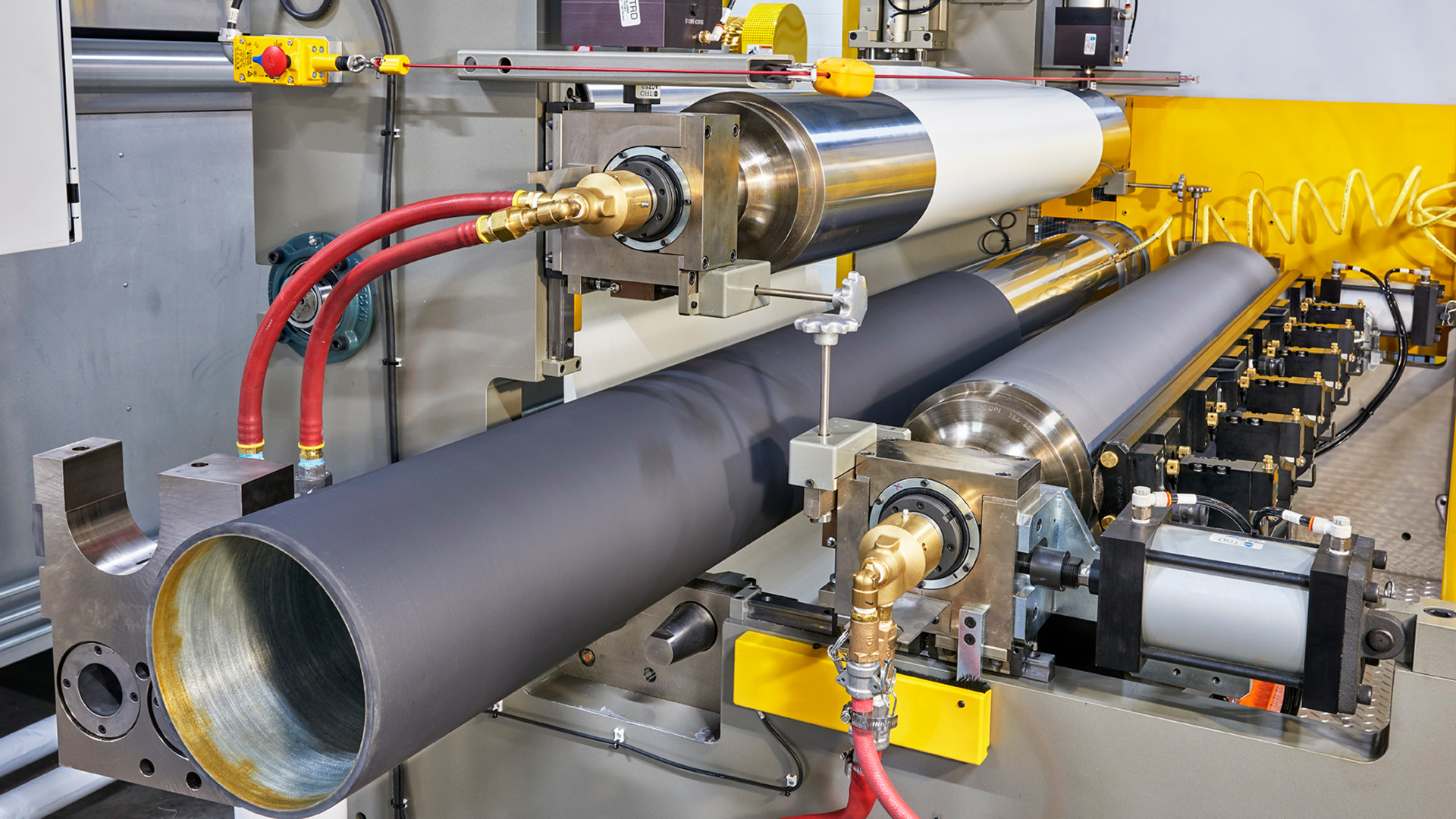

Web handling is the process of transporting thin, flexible materials—like films, foils, papers, textiles, or nonwovens—through a manufacturing process. These materials are typically shipped in rolls and require precise tension control, alignment, and handling to ensure high-quality finished products.

Key components of a web handling system include:

- Unwind and Rewind Stations: Smoothly feed and collect material rolls

- Web Accumulators: Maintain tension and allow for continuous production

- Roll Handling Equipment: Safely move and store large or heavy rolls

- Anti-Wrinkle and Spreading Systems: Ensure defect-free material transport

The Challenge: High-Speed Production Bottlenecks

The customer faced several production challenges:

- Frequent material jams and wrinkles, causing downtime

- Manual handling of large rolls, creating safety concerns and inefficiencies

- Difficulty maintaining consistent tension, leading to defects

- Limited scalability to support increasing production demands

These challenges were limiting output and preventing the customer from meeting delivery goals.

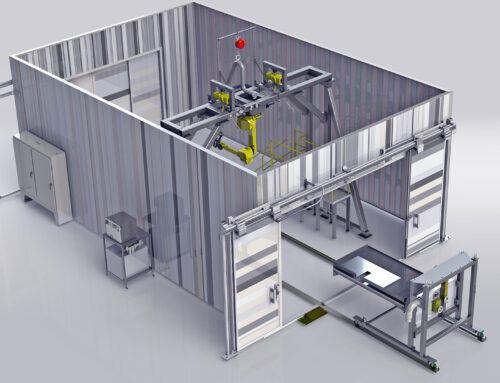

The MWES Solution: Custom Web Handling Automation

MWES engineers designed a custom web handling system tailored to the customer’s production needs. Key improvements included:

- Automated Unwind/Rewind Modules: Simplify roll changes and reduce operator intervention

- Integrated Web Accumulators: Maintain consistent tension across the entire line

- Anti-Wrinkle and Spreading Technologies: Prevent material defects at high speeds

- Enhanced Roll Handling Solutions: Reduce manual labor and improve safety

By implementing these solutions, MWES enabled the customer to streamline their process, reduce downtime, and increase throughput—ultimately doubling overall productivity.

Benefits of MWES Web Handling Systems

- Increased Production Efficiency: Faster, smoother material flow reduces downtime

- Consistent Product Quality: Eliminates wrinkles, tension inconsistencies, and defects

- Labor Savings: Automated systems reduce manual roll handling

- Scalable Solutions: Designed to adapt to evolving production requirements

- Enhanced Safety: Minimize the risk of injury with automated roll handling

Industries That Benefit

MWES web handling solutions serve a wide range of industries:

- Printing & Packaging: Consistent web feed for high-volume printing and laminating

- Flexible Electronics: Precise handling of delicate films and foils

- Textiles & Nonwovens: Smooth processing of woven and nonwoven materials

- Medical & Pharmaceutical: Reliable handling of sensitive materials

- Industrial Laminates & Coatings: Accurate processing for high-quality finishes

Take Action: Upgrade Your Web Handling

MWES provides custom web handling automation systems designed to maximize productivity, minimize waste, and improve operational efficiency. Our team works closely with customers to assess their process, design the optimal system, and implement solutions that deliver measurable results.

Request a Consultation today to learn how MWES can double your production efficiency and optimize your web handling operations.

Conclusion

Advanced web handling equipment can transform manufacturing workflows, improving both product quality and throughput. With MWES’s expertise in custom automation and web handling solutions, manufacturers can eliminate bottlenecks, reduce labor costs, and achieve scalable production growth.