Manufacturers today face a growing challenge: a generational skills gap that leaves critical roles unfilled and threatens production efficiency. As experienced workers retire, younger talent is harder to recruit and train. Midwest Engineered Systems (MWES) helps manufacturers bridge this gap with custom robotic automation solutions, enabling businesses to maintain productivity, reduce labor dependency, and ensure consistent quality.

The Challenge: A Shrinking Skilled Workforce

Across the U.S., manufacturers are experiencing:

- Retiring experienced workers with decades of specialized knowledge

- Difficulty attracting younger, skilled labor to technical roles

- Training bottlenecks, as new hires require extensive onboarding

- Production inefficiencies, resulting from inconsistent skill levels

- Rising labor costs due to scarcity of qualified workers

This skills gap threatens the ability to scale operations, maintain quality standards, and meet customer demands in an increasingly competitive market.

The MWES Solution: Robotic Automation That Fills the Gap

MWES provides custom automation systems designed to compensate for labor shortages and skill gaps:

- Collaborative Robots (Cobots): Work alongside human operators to handle repetitive or precise tasks, reducing reliance on highly specialized labor

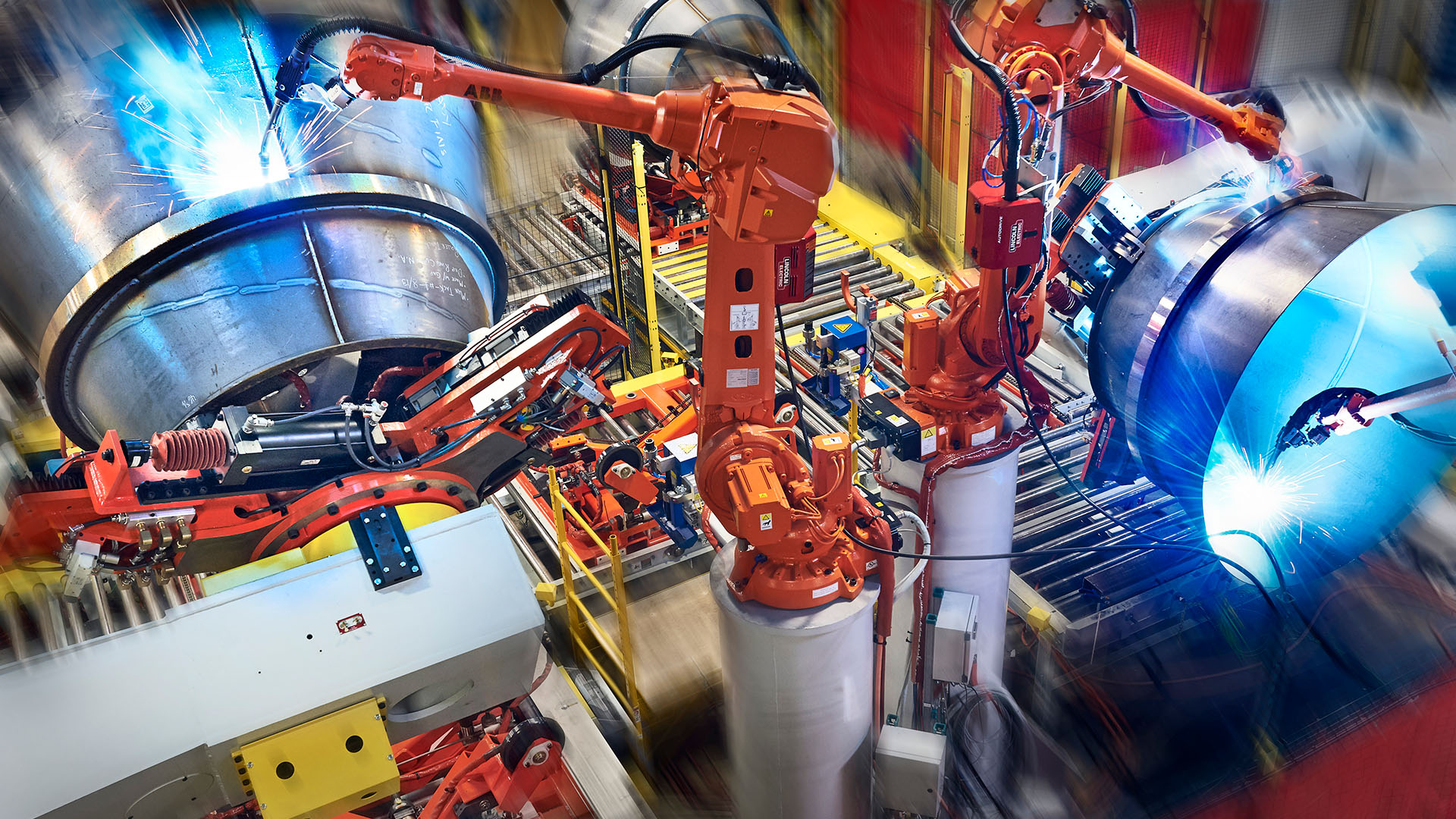

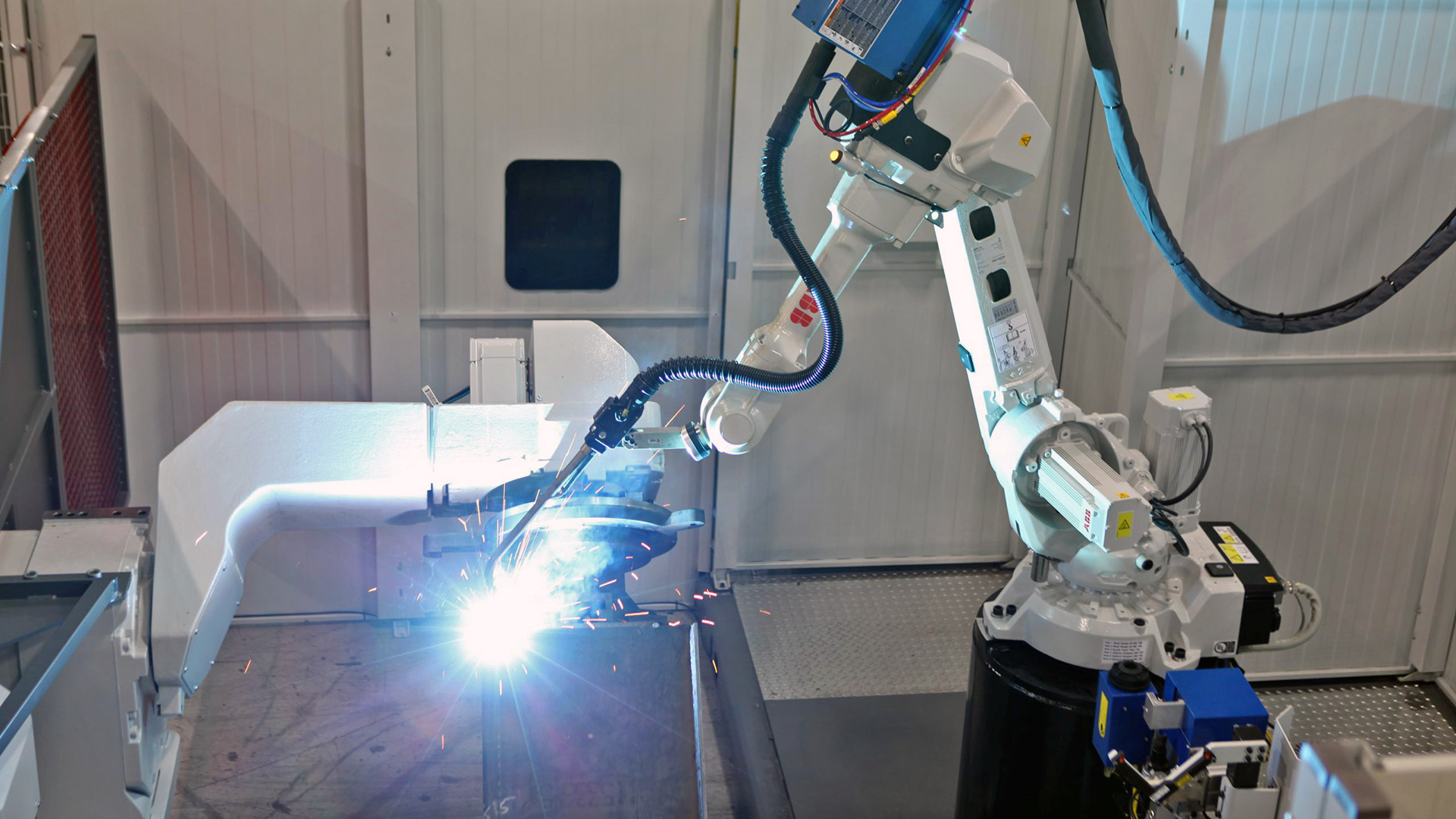

- Robotic Weld Cells: Maintain consistent quality and throughput even with fewer skilled welders

- Automated Material Handling: AGVs, AMRs, and conveyor systems streamline inventory movement and production line operations

- Integrated Training and Control Interfaces: User-friendly HMI and teach-button interfaces allow new operators to quickly manage complex systems

- Scalable Automation Solutions: Systems can be adapted as workforce availability and production needs evolve

By leveraging robotics, companies can maintain productivity levels while reducing training burdens and retaining operational knowledge in automated systems.

Benefits of Robotic Automation in Addressing the Skills Gap

- Increased Productivity: Automation performs repetitive, precise tasks reliably and continuously

- Reduced Dependence on Highly Skilled Labor: Machines handle complex operations, freeing skilled employees for high-value work

- Faster Training: User-friendly interfaces allow new operators to control systems efficiently

- Improved Quality and Consistency: Robots deliver repeatable performance, reducing defects and rework

- Long-Term Workforce Stability: Automation preserves operational knowledge and mitigates the impact of retirements

Industries That Benefit

MWES automation solutions support manufacturers in:

- Aerospace and defense

- Automotive and heavy machinery

- Medical device and pharmaceutical manufacturing

- Food and beverage production

- Industrial equipment and material handling

Any industry facing labor shortages or a retiring skilled workforce can benefit from strategic robotic automation.

Take Action: Close the Skills Gap with MWES Automation

MWES partners with manufacturers to design and implement automation systems that:

- Reduce dependency on scarce skilled labor

- Maintain consistent production quality

- Streamline training and onboarding

- Ensure long-term operational efficiency

Schedule a Consultation to see how robotic automation can bridge your workforce skills gap, improve throughput, and future-proof your manufacturing operations.

Conclusion

By embracing custom robotic automation, MWES helps manufacturers overcome the generational skills gap, optimize production, and retain operational knowledge. Automation solutions deliver reliable performance, consistent quality, and scalable productivity, ensuring businesses remain competitive in a changing labor landscape.