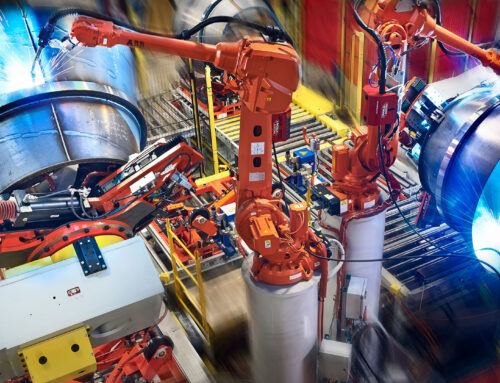

Manufacturing is evolving rapidly, and the transition from manual labor to robotic automation presents both opportunities and risks. Companies that successfully implement robotics can increase productivity, reduce labor costs, and improve safety, but poorly planned transitions can lead to downtime, employee resistance, and costly errors. MWES helps manufacturers navigate this shift with proven strategies and customized automation solutions.

The Challenges of Transitioning to a Robotic Workforce

Manufacturers face multiple risks when moving from manual to robotic processes:

- Employee Resistance: Staff may fear job loss or struggle to adapt to new roles

- Process Downtime: Mismanaged integration can disrupt production

- Training Gaps: Operators may lack experience with robotics and automation systems

- System Compatibility: Robots and software must seamlessly integrate with existing equipment

- ROI Uncertainty: Without careful planning, automation may not deliver expected productivity gains

Understanding these challenges upfront is critical to ensuring a smooth, cost-effective transition.

How to Mitigate Risks During Automation Adoption

- Comprehensive Planning and Assessment

Evaluate existing processes, production goals, and workforce needs to identify where automation adds the most value.

- Employee Engagement and Training

Involve employees early in the transition and provide hands-on training to reduce resistance and empower staff to work alongside robots.

- Phased Implementation

Start with pilot projects or semi-automated systems to test workflows, identify bottlenecks, and refine integration strategies before scaling.

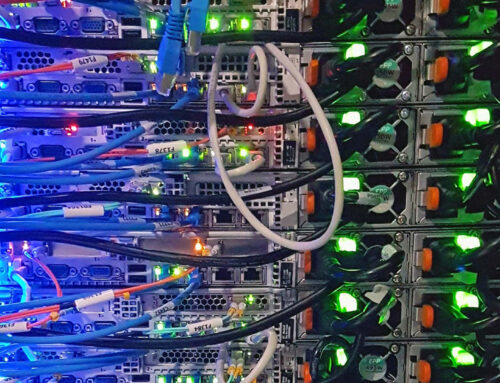

- Integration with Existing Systems

Ensure robotic systems seamlessly connect with conveyors, assembly lines, and software platforms to minimize disruption and maximize efficiency.

- Continuous Monitoring and Optimization

Leverage data-driven insights and AI to fine-tune robotic operations, reduce downtime, and maintain consistent quality.

Benefits of a Successful Transition

When implemented effectively, transitioning to a robotic workforce offers measurable advantages:

- Increased Productivity: Robots handle repetitive, high-volume tasks faster and more accurately

- Labor Cost Savings: Reduce reliance on manual labor while upskilling employees for higher-value work

- Improved Safety: Robots manage physically demanding or hazardous tasks

- Enhanced Quality and Consistency: Automation reduces human error and ensures repeatable results

- Scalability: Flexible automation solutions grow with production needs

MWES’ Approach to Robotic Workforce Integration

MWES partners with manufacturers to de-risk automation adoption:

- Custom Automation Solutions: Tailored robotic systems designed for your workflow and production goals

- Employee-Focused Training: Ensuring operators can safely and efficiently work with robots

- Seamless Integration: Systems that work with your existing equipment and software

- Support and Optimization: Ongoing maintenance, programming, and process improvement

- ROI-Focused Design: Automation solutions that deliver measurable cost savings and efficiency gains

Take Action: Make Your Automation Transition Smooth

The shift from manual labor to robotic automation doesn’t have to be disruptive. With MWES’ expert guidance and custom automation solutions, you can maximize efficiency, reduce risk, and empower your workforce for the future.

- ✅ Schedule a Consultation

- ✅ Discover how MWES can design and integrate robotics to match your production needs

- ✅ Learn how to train and transition your workforce effectively

Conclusion

Transitioning to a robotic workforce is a strategic move that can boost productivity, reduce costs, and improve workplace safety. By partnering with MWES, manufacturers can mitigate risks, ensure seamless integration, and achieve lasting operational improvements.