Waukesha, WI — Midwest Engineered Systems, Inc. (MWES) has announced its registration with the Bakery Equipment Assessment Group (BEAG), reinforcing its ongoing commitment to advancing hygienic equipment design within the baking industry. The announcement precedes MWES’s exhibition at the upcoming International Baking Industry Exposition (IBIE) in Las Vegas.

The Bakery Equipment Assessment Group is a not-for-profit organization that collaborates with equipment manufacturers to evaluate conformance with the latest American National Standards Institute (ANSI) standards for hygienic design. Their mission is to strengthen the baking industry’s commitment to safe, sanitary, and hygienic equipment practices.

“We’re excited to be part of BEAG as they build awareness of ANSI standards for baking equipment,” said Chuck Sena, Food Solutions Business Unit Manager at MWES. “As an equipment supplier, our contribution to food safety is delivering automation systems that are easy to clean, sanitize, and maintain—helping prevent contamination and protect the integrity of our food supply.”

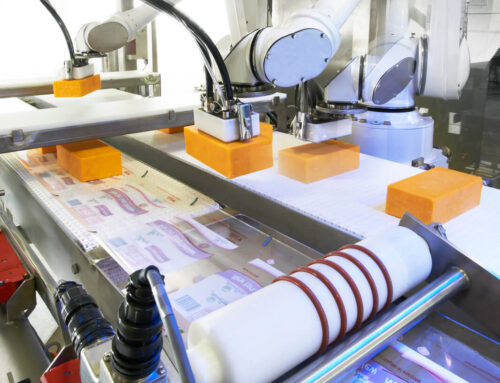

MWES’s registration with BEAG reflects the company’s dedication to designing and building food-grade automation solutions that meet the highest safety and sanitation standards. The MWES Food Solutions Group focuses on robotic and automation systems for the food and beverage industry that improve labor efficiency, reduce waste, increase throughput, and enhance food safety across production lines.

In addition to BEAG, MWES actively participates in other key food industry associations, with company representatives serving on the Board of Directors and Bakery Council of the Food Production Solutions Association (FPSA), as well as the CCE Coordinating Committee for 3-A Sanitary Standards. MWES is also a proud supplier member of the Wisconsin Cheese Makers Association (WCMA) and the Retail Bakers of America.

“This collaboration with BEAG builds on MWES’s long history of automating complex manufacturing processes in the food industry,” added Sena. “Our ability to deliver solutions—from single operations to fully integrated, turnkey systems—helps food processors of all sizes enhance safety, productivity, and profitability.”

For more than 30 years, Midwest Engineered Systems Inc. (MWES) has been a leader in automation system integration, delivering over 8,000 solutions worldwide. From robotic welding and material handling to food-grade automation and large-scale production lines, MWES designs, builds, and services automation systems that drive innovation, quality, and efficiency across industries.