Bringing a product from concept to production is complex and full of potential pitfalls. Ensuring your designs are manufacturing-ready is crucial for reducing costs, shortening time-to-market, and avoiding costly rework. Midwest Engineered Systems (MWES) helps manufacturers assess product readiness, streamline processes, and integrate automation to maximize efficiency and quality.

What Does “Manufacturing-Ready” Mean?

A product is manufacturing-ready when it can be produced efficiently, consistently, and at scale. Key factors include:

- Design for Manufacturability (DFM): Optimized for assembly, minimal handling, and reduced material waste

- Material Selection: Using materials that meet performance, cost, and production requirements

- Process Compatibility: Ensuring parts can be fabricated and assembled using existing or automated production processes

- Quality Assurance Considerations: Features designed to minimize defects and simplify inspection

- Automation Feasibility: Parts designed for robotic assembly, welding, or material handling where applicable

A product that meets these criteria can move quickly from prototype to production, saving both time and money.

The Challenge: Product Designs That Fall Short

Many companies face delays and cost overruns because designs aren’t fully prepared for manufacturing. Common issues include:

- Parts that are difficult to handle manually or with robots

- Designs that require excessive machining or assembly steps

- Materials that don’t perform reliably in production environments

- Features that cause quality defects or rework

- Poor integration with automated systems, limiting efficiency

These challenges can lead to bottlenecks, increased labor costs, and extended time-to-market.

The MWES Solution: Assess, Optimize, Automate

MWES works with manufacturers to ensure products are ready for production at scale. Our approach includes:

- Comprehensive Product Evaluation: Review designs for manufacturability, material selection, and automation readiness

- Process Optimization: Recommend changes to simplify assembly, reduce labor, and improve consistency

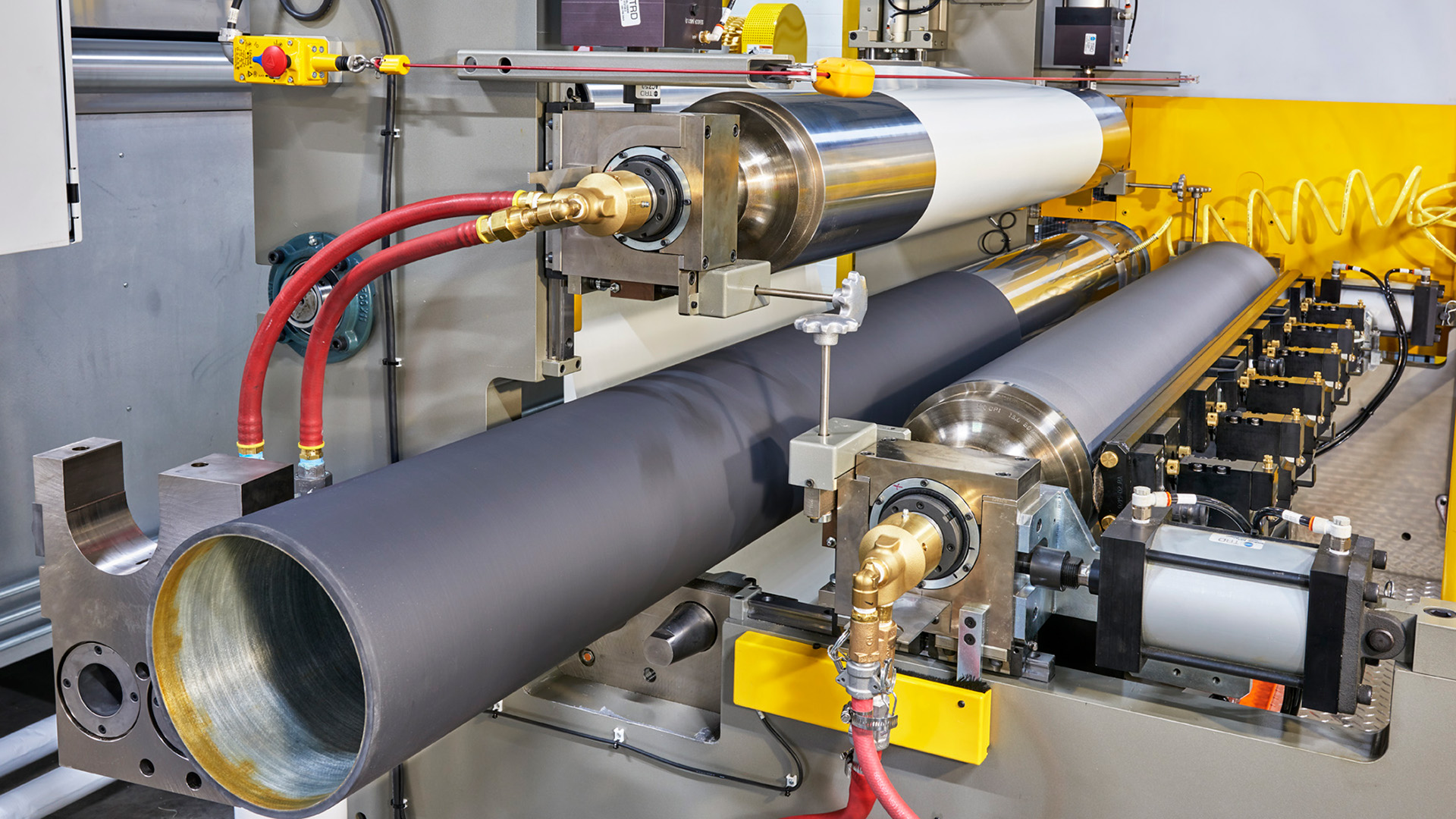

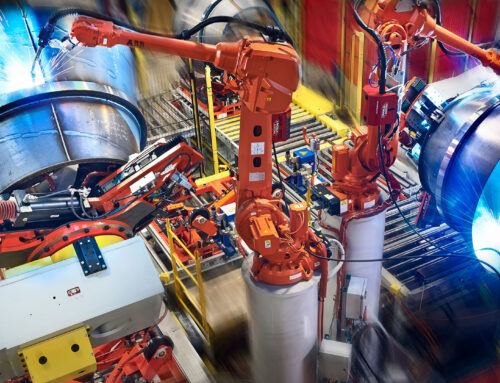

- Automation Integration: Identify opportunities for robotic assembly, material handling, welding, and inspection

- Prototyping & Testing: Validate the design under production conditions to minimize risk before full-scale manufacturing

By addressing these areas upfront, MWES helps manufacturers avoid costly errors, accelerate production, and improve ROI.

Benefits of Manufacturing-Ready Products

- Reduced Time-to-Market: Streamlined processes enable faster production ramp-up

- Lower Production Costs: Efficient designs minimize labor, rework, and material waste

- Improved Product Quality: Fewer defects, better consistency, and enhanced reliability

- Scalability: Designs ready for automated production systems support higher volumes

- Risk Mitigation: Early identification of design and process issues reduces costly delays

Take Action: Prepare Your Products for Manufacturing

Whether you’re launching a new product or improving an existing one, MWES can help ensure your designs are production-ready. Our team of experts will evaluate, optimize, and integrate automation to streamline your manufacturing processes.

Schedule a Consultation today and ensure your products are ready for efficient, scalable, and high-quality production.

Conclusion

Designing products for manufacturing requires careful planning, evaluation, and optimization. With MWES’s manufacturing readiness services and expertise in automation and custom production systems, you can reduce costs, accelerate production, and achieve consistent quality for every product you produce.