The Challenge

Outgrowing Legacy Coating Capabilities Amid Rising Demand

As product demand and customer requirements evolved, the manufacturer’s existing coating equipment couldn’t keep up. MWES was brought in to deliver a future-ready solution that could scale performance and material flexibility.

- Legacy system limited to 36-inch web widths and 400 FPM speed

- Increasing demand for wider rolls and larger roll diameters

- Needed greater flexibility for varied substrates and coat weights

- Required inline printing and advanced drying to reduce equipment redundancy

The customer needed a more advanced, integrated system to improve throughput, flexibility, and coating quality—all while handling diverse substrates with high precision.

The Solution

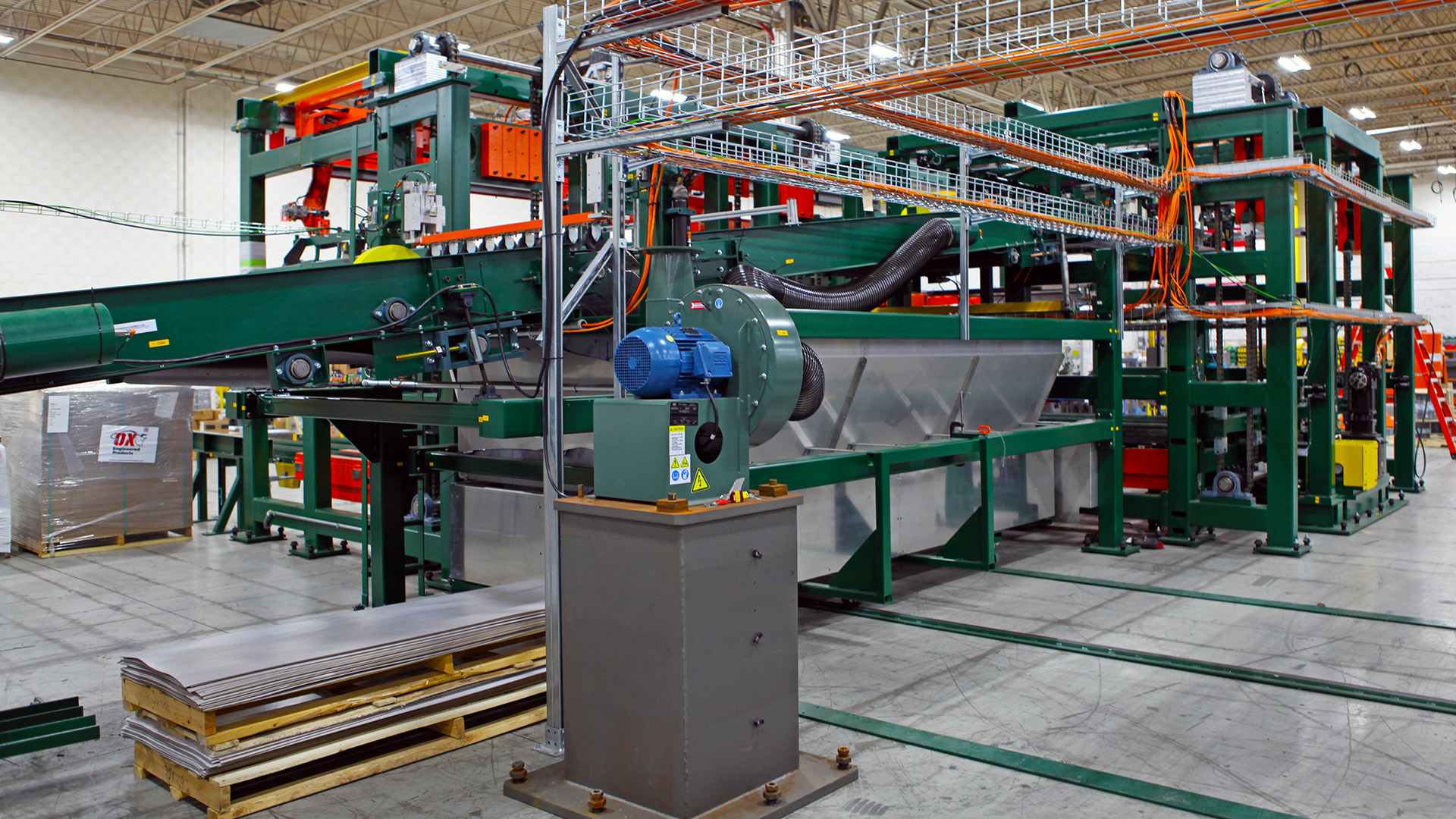

65-Inch Gravure Silicone Coating System with Integrated Flexo Printing & Advanced Web Handling

MWES engineered a complete coating line with best-in-class components and controls to deliver high-speed, high-precision performance across multiple substrate types and coating applications.

- Shaftless unwind handles rolls up to 5,000 lbs and 52″ diameter

- Integrated flexographic print module for inline backside printing

- Gravure coater with quick-change rolls and HMI-driven speed ratios

- Two-zone flotation dryer cures coatings at up to 450°F efficiently

- Chill rolls and CMS moisturizer reduce curl and control web temperature

- Precision rewind system supports up to 65-inch wide, 50-inch rolls

- Integrated shear slitting and Accuweb guidance ensure accuracy

- Allen Bradley vector drives and safety PLC provide control and diagnostics

Every stage—from unwinding through rewinding—was optimized for web tension control, coating consistency, substrate alignment, and speed.

The modular system architecture allows for recipe-driven operation, safe manual interaction, and long-term scalability.

The Results

2X Faster Production with Improved Substrate Versatility & Lower Labor Demands

MWES’s solution enabled the manufacturer to meet growing production demands while gaining new capabilities and greater operational efficiency.

- Doubled web speed from 400 FPM to 1,000 FPM

- Expanded web width from 36″ to 65″, increasing product flexibility

- Integrated inline printing, eliminating need for a separate machine

- Enhanced coat weight and substrate control through advanced tension systems

- Reduced curl, improved drying, and minimized manual intervention

This high-efficiency line delivered faster turnaround, better substrate handling, and higher coating quality—all key to staying competitive in a growing market.