The Challenge

Delivering Repeatable, Inert Lubrication Without Human Variability

Coating medical-grade injection devices demands extreme consistency and cleanliness to meet performance and regulatory standards. The customer needed automation to:

- Eliminate variation caused by manual coating techniques

- Ensure precise spray volumes and uniform coating coverage

- Integrate plasma treatments to enhance adhesion and performance

- Provide in-line quality verification and defect rejection

MWES was selected to design a zero-touch process that unifies coating, treatment, and inspection in a stable, repeatable workflow.

The Solution

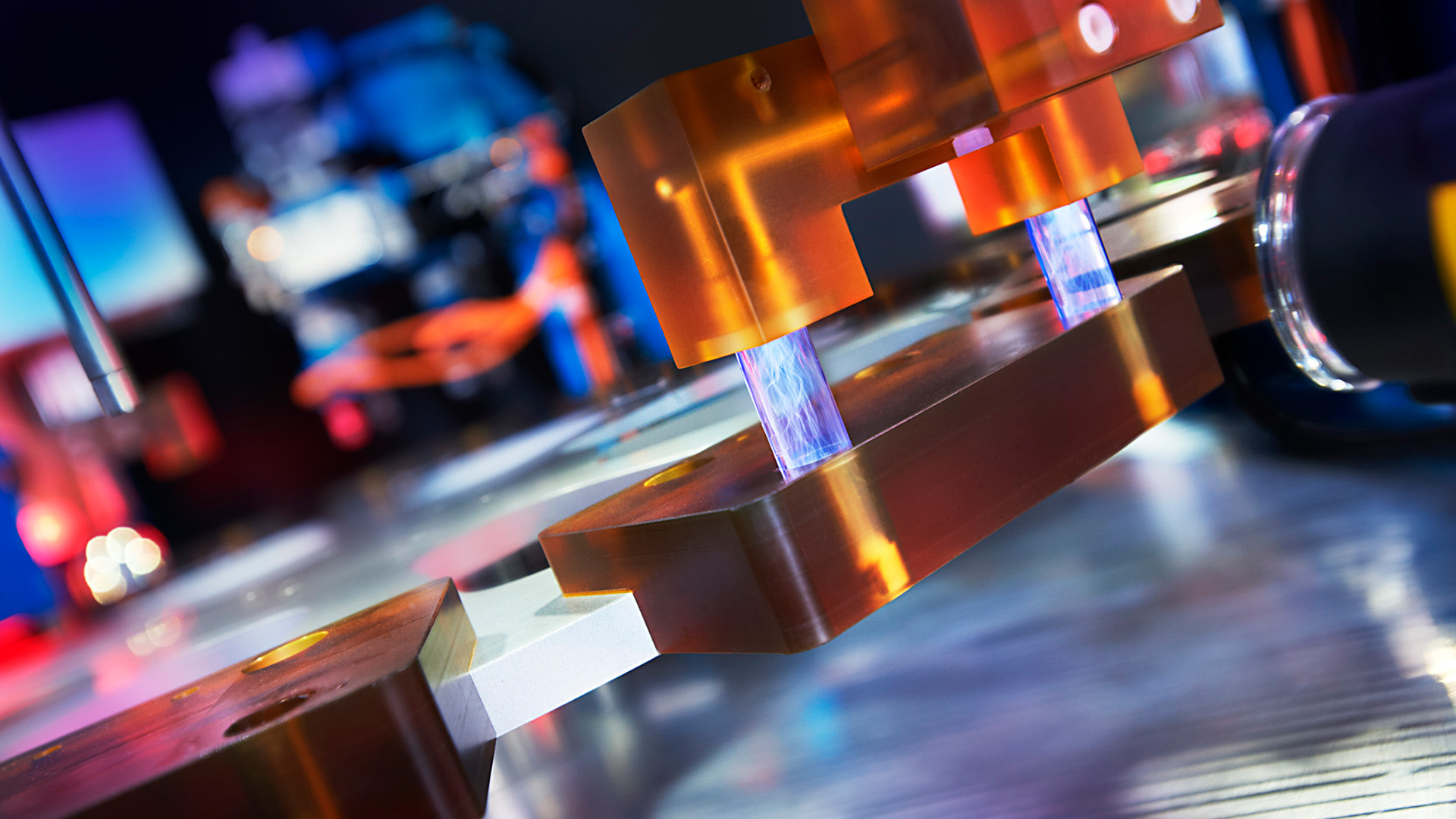

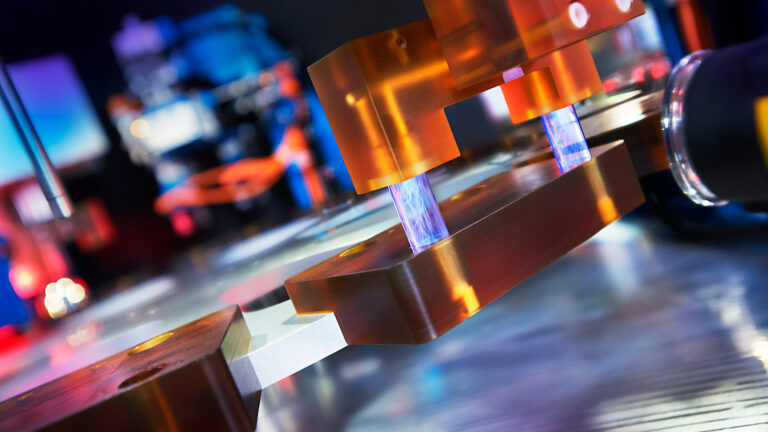

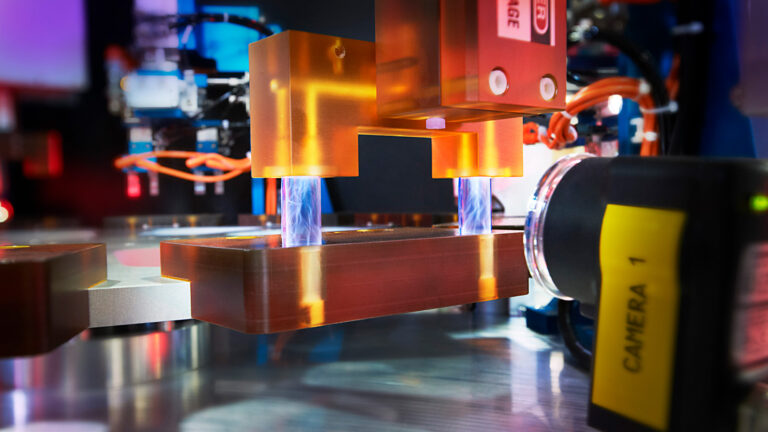

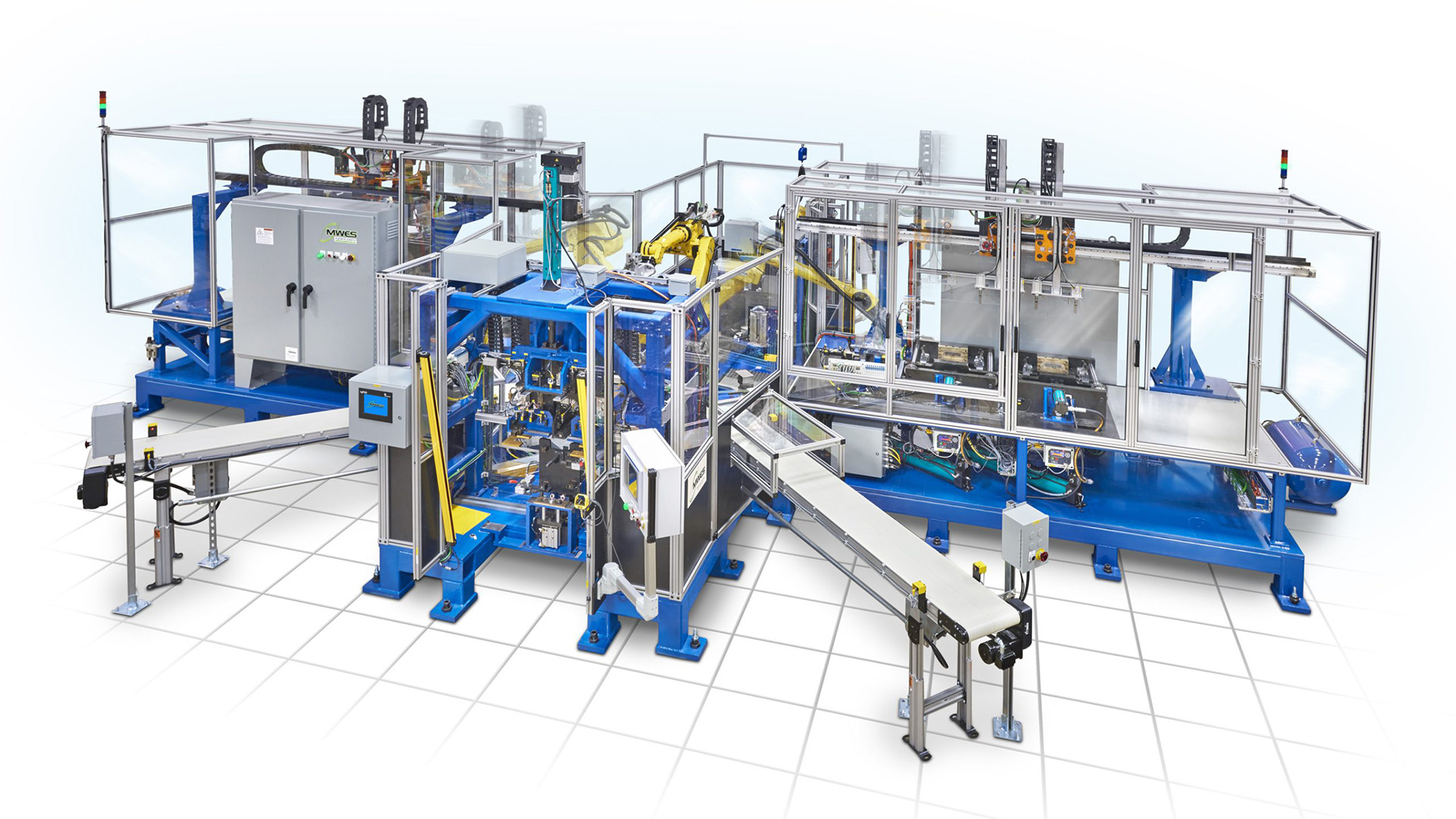

Six‑Station Rotary Machine with Plasma Treatment, Spray Coating & Vision QC

MWES developed a compact rotary coating cell featuring:

- Vibratory bowl feeder to orient and load parts into nests

- Six-station servo-driven rotary dial guiding parts through the process

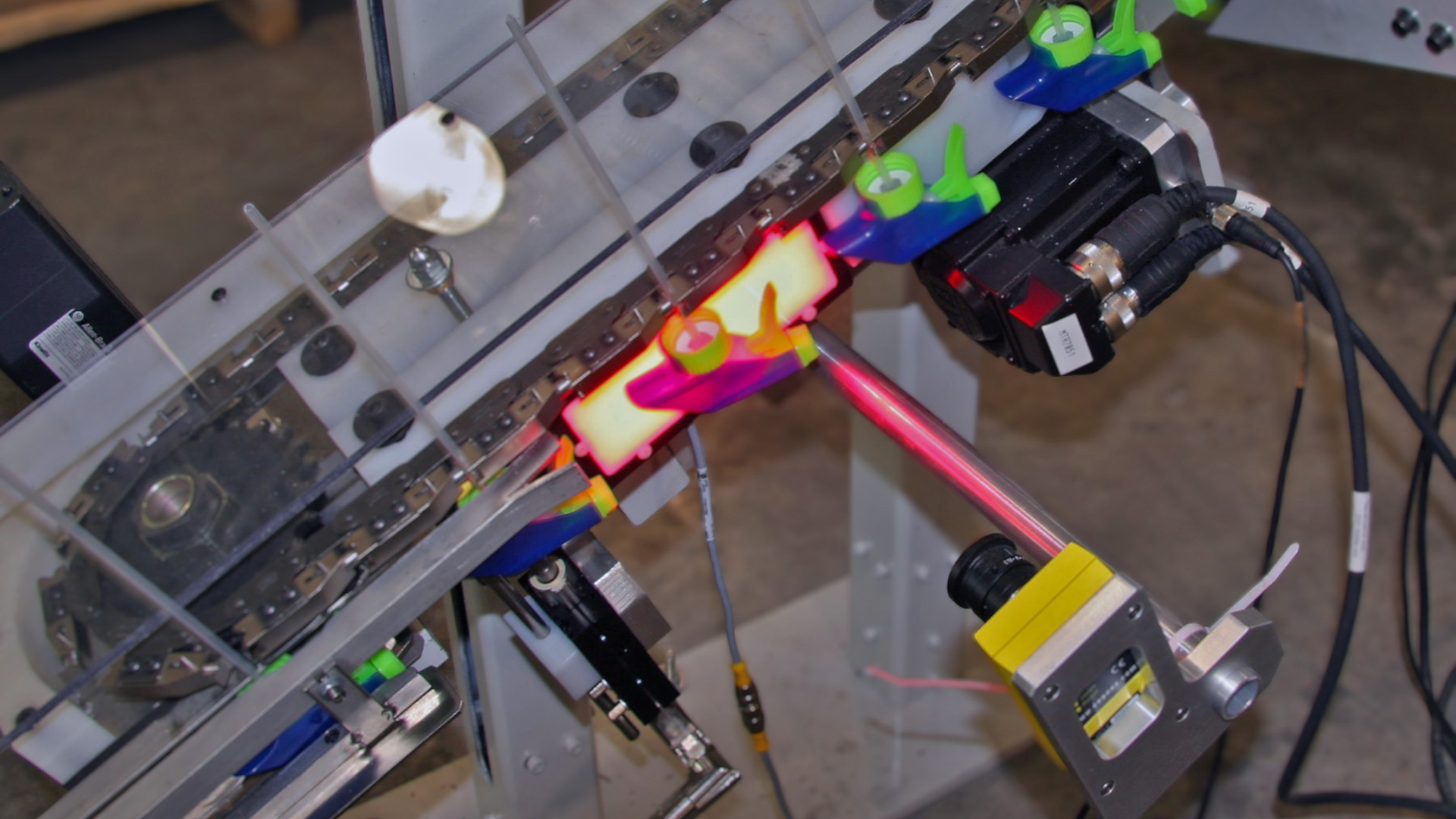

- Pre-plasma treatment to ionize and clean surfaces before coating

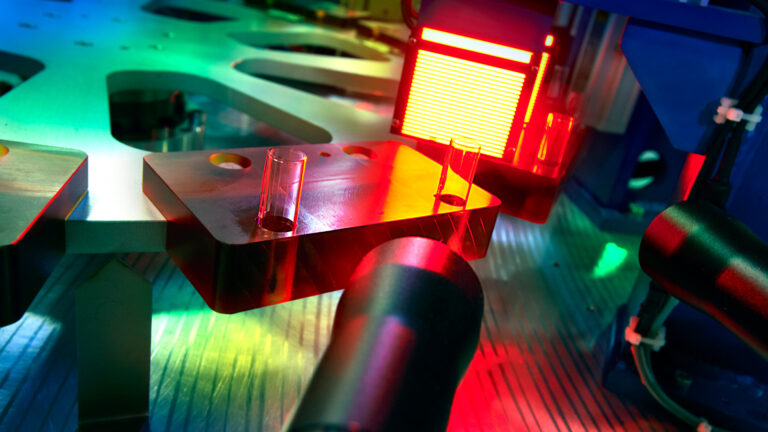

- Precision spray coating with proprietary lubricant using fluid dispensers

- Vision inspection to verify coating uniformity and part presence

- Post-plasma treatment to finalize lubrication properties

- Reject chute for out-of-spec parts detected during vision inspection

The result is a fully automated coating line that feeds, treats, coats, inspects, and rejects parts across all operations with minimal operator touch.

In summary, the rotary system automates all critical stages—preparation, coating, inspection, and rejection—enabling reliable, repeatable coating performance without human intervention.

The Results

Scalable Surgical-Grade Coating with Traceable Quality and Rapid Scale‑Up

The MWES system delivered measurable benefits across throughput, quality, and compliance:

- Enabled volume-scalable coating to meet customer demand growth

- Maintained consistent lubricant distribution on critical medical components

- Reduced operator error and variation through automated, closed-loop inspection

- Met performance and repeatability requirements essential for medical device manufacturing

By merging inert lubrication, plasma adhesion, and machine-vision quality verification in one cell, MWES enabled a reproducible, scalable coating process for medical-grade parts—meeting the customer’s demand for high throughput and consistent quality.