The Challenge

Applying Durable Coatings on Diverse Substrates at High Speed

Meeting the demand for labels with UV- and frost-resistant adhesives presented multiple constraints:

- Uniformly apply hot melt adhesive to substrates including paper, film, liners, and metallized materials

- Control web handling and coating quality across variable widths and high line speeds

- Avoid substrate distortion by precise tension and chill control

- Handle heavy rolls up to 2,500 lb without downtime or safety risks

MWES was selected to build an integrated coating system capable of processing varied materials with consistent coating performance.

The Solution

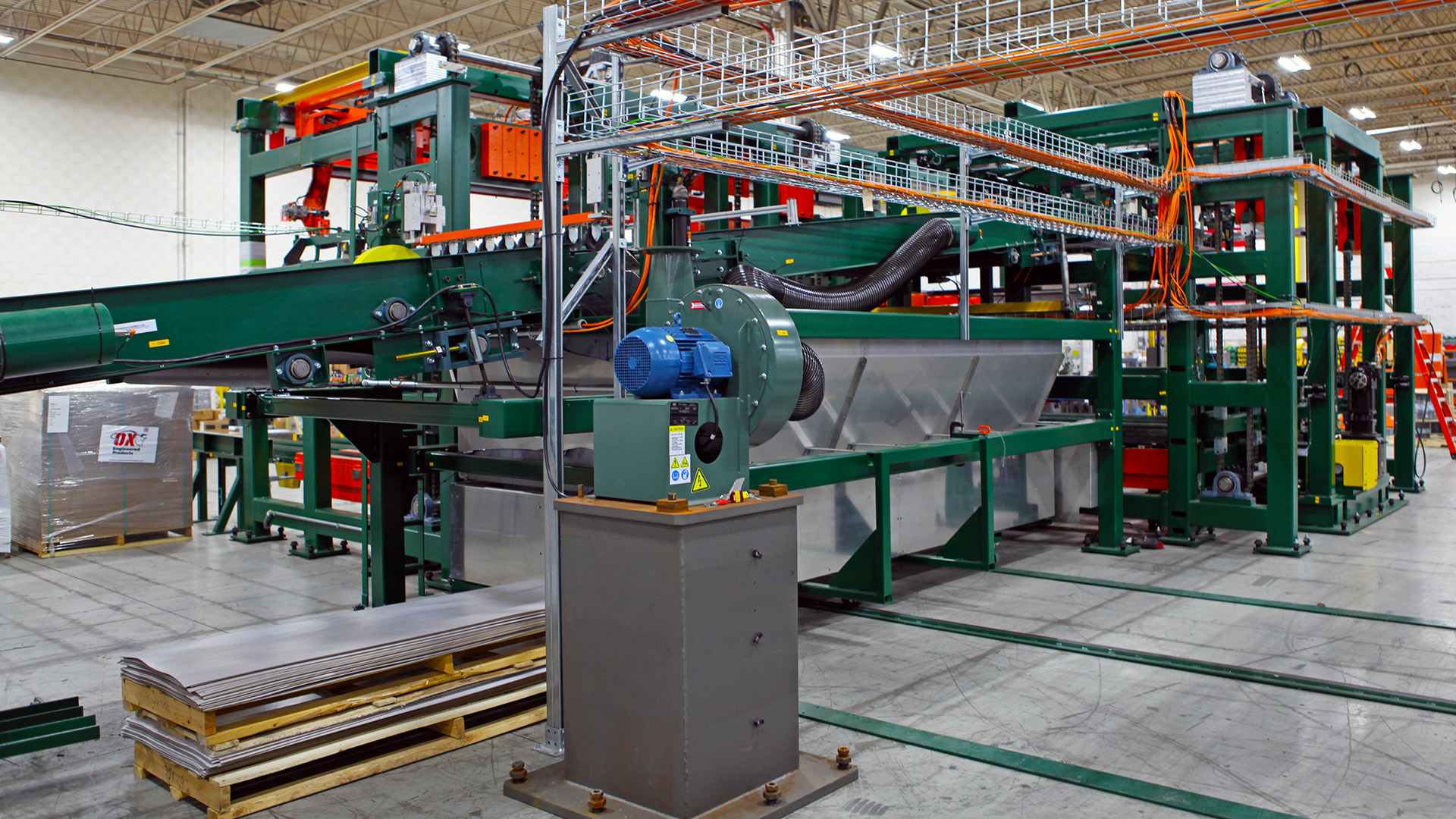

Custom Hot Melt Coating Web Line with Nordson Coating & Rexroth Control

MWES delivered a full coating and web handling solution, including:

- Dual unwind spindles and infeed pull-nip for stable web feed

- Nordson Coating System with precise thermal melt application

- Die coater backing roll paired with chill roll for immediate adhesive solidification

- Full rewind assembly powered by Bosch‑Rexroth AC drives with HMI touch interface

- Line configuration supporting 27–40 in web widths and operating speeds from 50 to 500 FPM

- Ability to process rolls up to 2,500 lb to minimize changeovers and improve roll life

This turnkey installation automates adhesive coating on multiple substrates at high speed, while maintaining web stability and operator safety.

The Results

Wide-Substrate Capability, High Throughput & Durable Adhesive Performance

The new system delivered significant enhancements:

- Enabled coating of various materials—paper, film, liners, and metalized substrates

- Process speeds from 50 up to 500 FPM without sacrificing adhesive quality

- Eliminated substrate distortion through optimized chill and tension control

- Increased production capacity and supported harsh-environment label output

By integrating coating, chill, and rewind modules, MWES empowered the customer to produce high-performance adhesive labels at scale—with consistency, speed, and substrate flexibility.