The Challenge

Scaling Bag Production Across Sizes While Keeping Equipment Simple

To meet rising demand, the customer needed a flexible, high-speed bag-making system that could:

- Process a wide range of polyethylene thicknesses (1–6 mil)

- Produce bag widths from 8″ to 53″ and minimum lengths of 6″

- Run continuously with minimal operator supervision

- Maintain compliance with safety standards while delivering high output

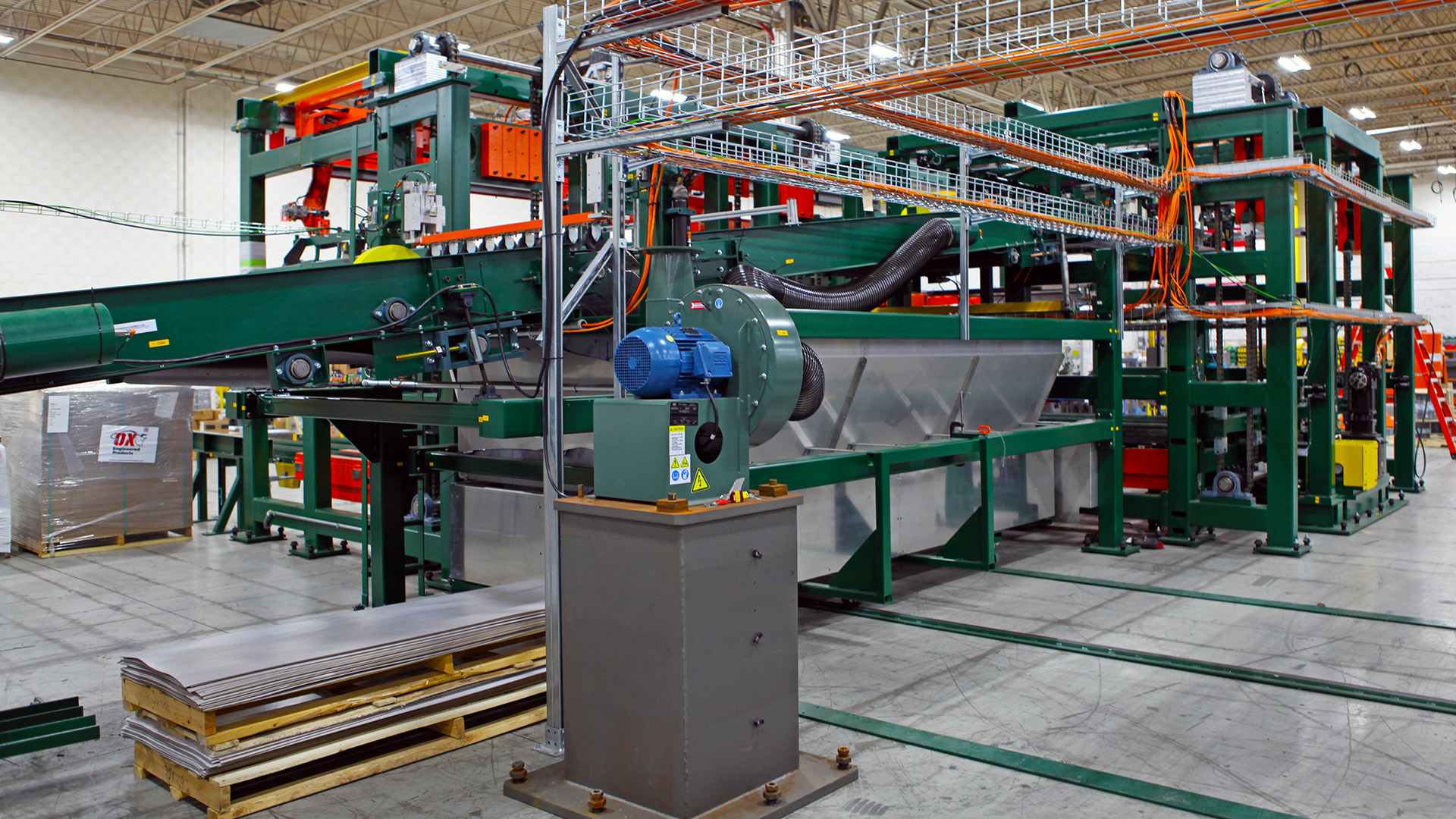

MWES was selected to engineer an advanced web-handling cell that supported multiple bag sizes and materials—all in a single machine footprint.

The Solution

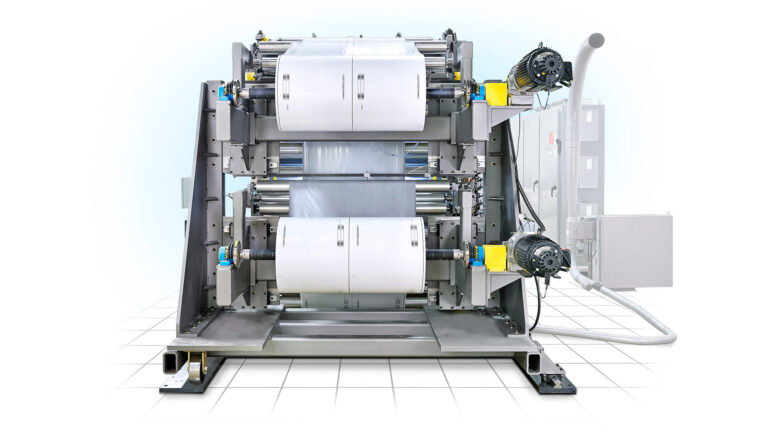

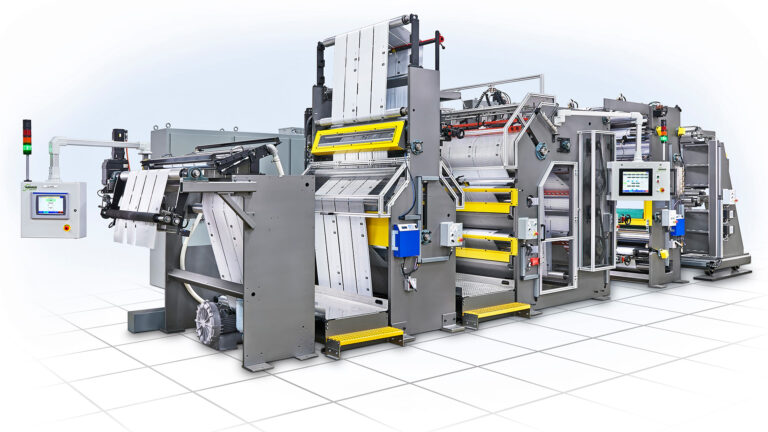

Automated Web Handling System with Inline Bag Forming and Cutting

MWES delivered a complete bag-making cell featuring:

- Web unwinding, joining, and trimming for polyethylene sheets up to 56″ wide

- Dynamic sealing and cutting systems to produce defined-length bags

- Variable controls to accommodate 1–6 mil film thickness and bag size flexibility

- Automated collection of finished bags into containers for downstream operations

The system runs at speeds of up to 93 feet per minute, producing 42–132 bags per minute, depending on bag width—fully automating production and minimizing manual intervention.

In summary, the machine integrates web handling, trimming, sealing, and bag collection into a single high-speed process—providing a scalable solution for varied polyethylene bag production.

The Results

High Capacity, Operator-Efficient Bag Making with Clean Output

This turnkey system delivered measurable benefits including:

- Output rates of 42–132 bags per minute based on width

- Reduced manual handling with only one operator needed per shift

- Reliable operation across varied film thicknesses and bag sizes

- Improved uptime and throughput over legacy OEM equipment

By designing a versatile, high-speed web handling cell, MWES enabled the customer to modernize polyethylene bag production—dramatically increasing output and reducing labor demands.