The Challenge

Upgrading a Legacy Laminating Line Without Full Replacement

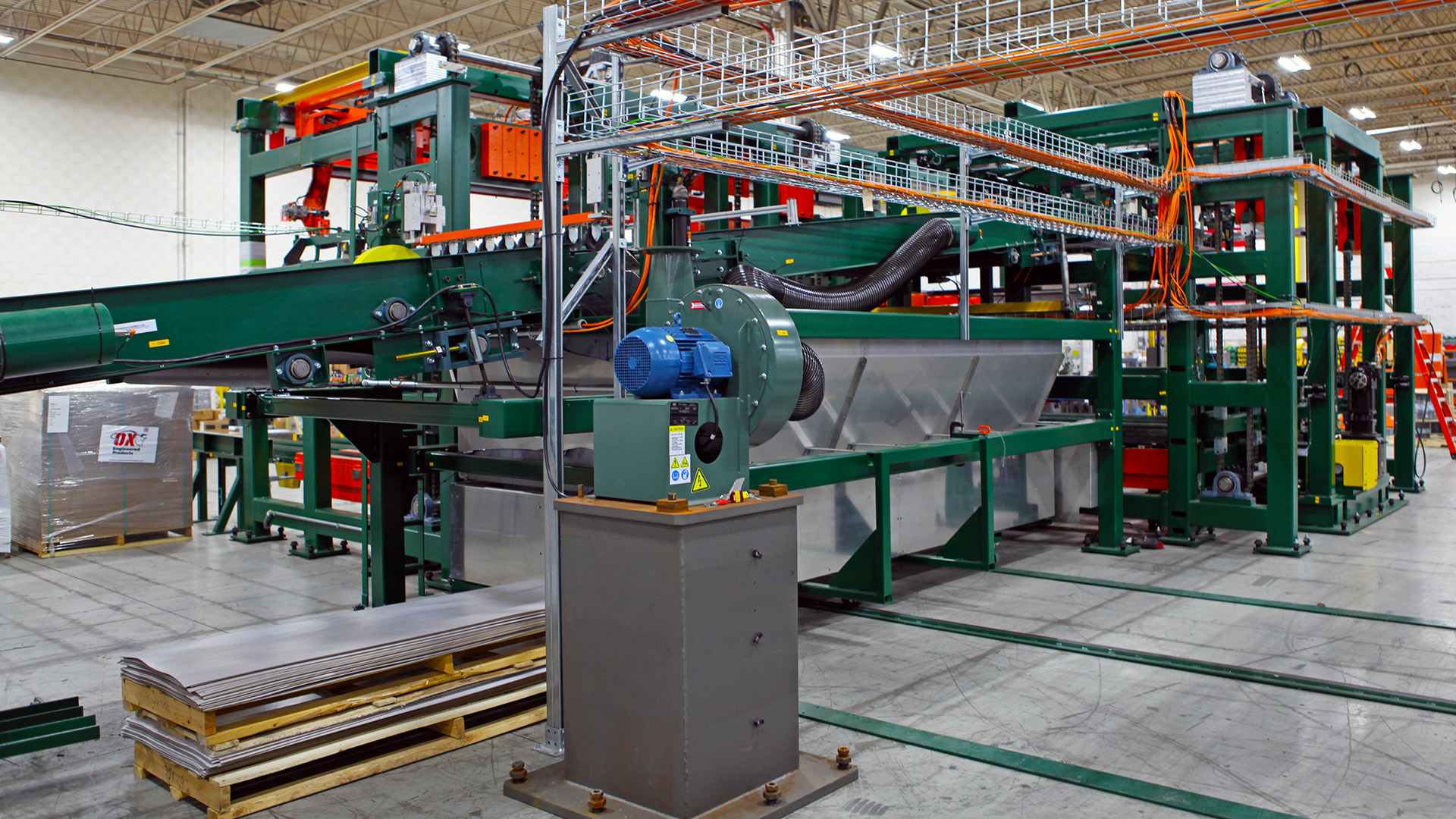

Enhancing an existing coating-laminating line presented multiple integration obstacles. The customer needed a solution to:

- Add new unwind and rewind capability to the line

- Install hoist rails and upright support structures for additional idlers

- Seamlessly integrate with existing SSI 90 slitter and main drive systems

- Maintain consistent tension, alignment, and control across new and legacy equipment

MWES was chosen for its expertise in retrofitting web-handling systems and adding capabilities to live production lines.

The Solution

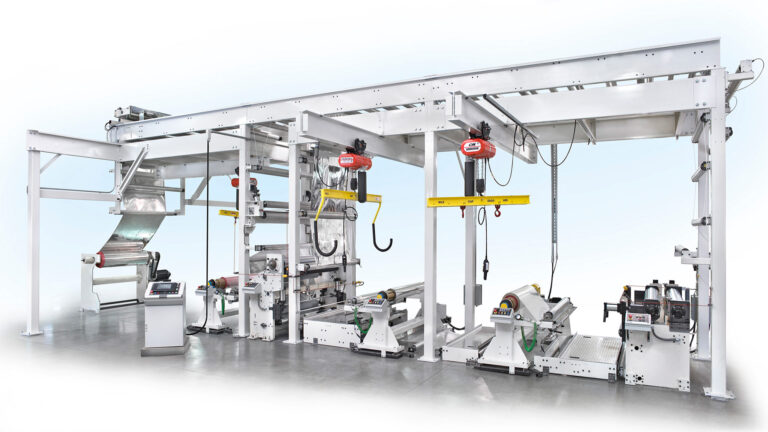

Modular Web Handling Additions Integrated with Legacy Lamination System

MWES delivered a retrofit package featuring:

- Two new unwind/rewind modules mounted on hoist rails supported by I‑beam structures

- Four upright supports carrying 18 idler rollers and two stripping units

- Retained customer-supplied SSI 90 Slitter and main drive cabinet integration

- Allen-Bradley PLC with PanelView HMI to unify operator interface and control

This solution extended line capability without disruption: the new unwind, rewind, rail, and support structures integrated smoothly with existing lamination sections and control systems.

The Results

Improved Throughput, Lower Cost & Extended Equipment Life

The upgrade delivered immediate operational gains:

- Increased total line throughput without a full system rebuild

- Added components operated under existing control and drive infrastructure

- Enhanced system flexibility and capacity with minimal capital expense

- Improved ROI by maximizing the value of installed equipment

By strategically extending the existing line, MWES helped the customer scale production efficiently, reduce upgrade costs, and maintain process consistency within their established lamination workflow.