The Challenge

Automating Complex Welds While Reusing Legacy Equipment

This medical equipment manufacturer needed to improve production of large MRI components by automating a precise welding process. The key goals were:

- Replacing skilled manual welding with robotic precision

- Handling large OVC (Outer Vacuum Chamber) shells with minimal operator input

- Reusing existing components already installed at the customer’s facility

- Ensuring weld consistency across carbon and stainless steel joints

MWES was selected to deliver a solution that could automate a difficult weld process while maximizing existing asset utilization.

The Solution

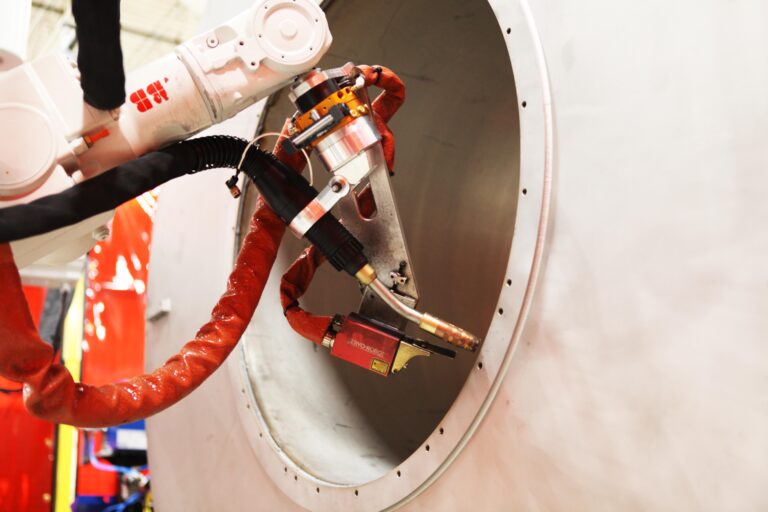

Track-Mounted ABB Robot with Torch Switching, Scanning & Cleaning

MWES provided a turnkey robotic welding cell featuring:

- An ABB IRB800 robot mounted on a floor track to reach the full weld envelope

- Automated tool changing between carbon steel and stainless steel torches

- Laser scanning to verify joint and part features before each weld

- Integrated torch maintenance station for in-cycle cleaning

- Operator-guided part loading with HMI verification and cycle initiation

- Smart program logic to handle multiple weld types and part positions

The robotic system uses sensors and scanning to ensure positional accuracy before initiating welds—enabling the entire welding cycle to be completed with minimal operator intervention.

The Results

Skilled Weld Replacement with Minimal Labor and Fast ROI

This fully automated system delivered strong results for the customer:

- Replaced labor-intensive welding with precise, repeatable robotic automation

- Reduced skilled welder dependence in a competitive labor market

- Enabled a single operator to run the full process safely and efficiently

- Increased throughput while maintaining high weld quality

- Reused existing carts and infrastructure for cost-effective integration

MWES helped the customer achieve greater productivity, reduced labor reliance, and a faster return on investment by automating a key manufacturing step in MRI machine production.