The Challenge

Automating Large Welds on Heavy Transformer Covers

Ultimately, the customer needed to eliminate repetitive welding inconsistencies and cut reliance on manual labor for handling large housings. Their requirements included:

- Welding top covers onto transformers ranging from 1,000 to 3,750 KVA

- Achieving high repeatability and precision in weld seams

- Eliminating dependence on manual tacking and welding labor

- Maintaining high throughput without sacrificing quality

MWES was selected for their expertise in robotic weld cells capable of handling large transformer weld applications reliably.

The Solution

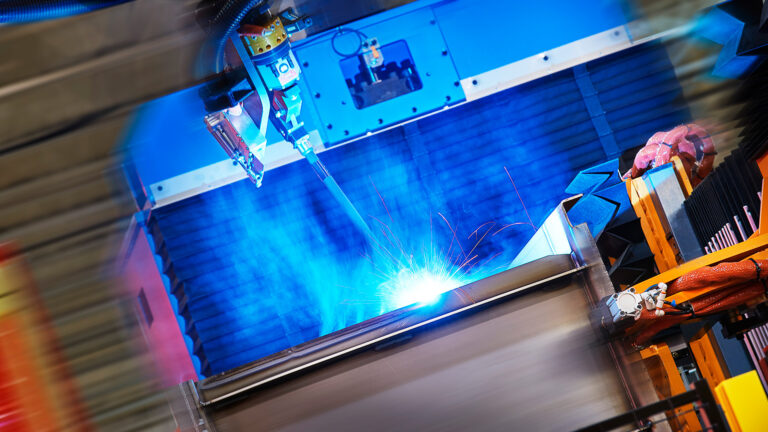

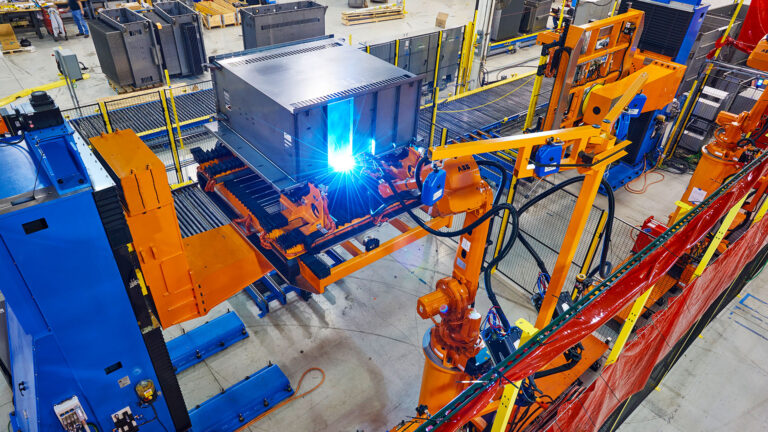

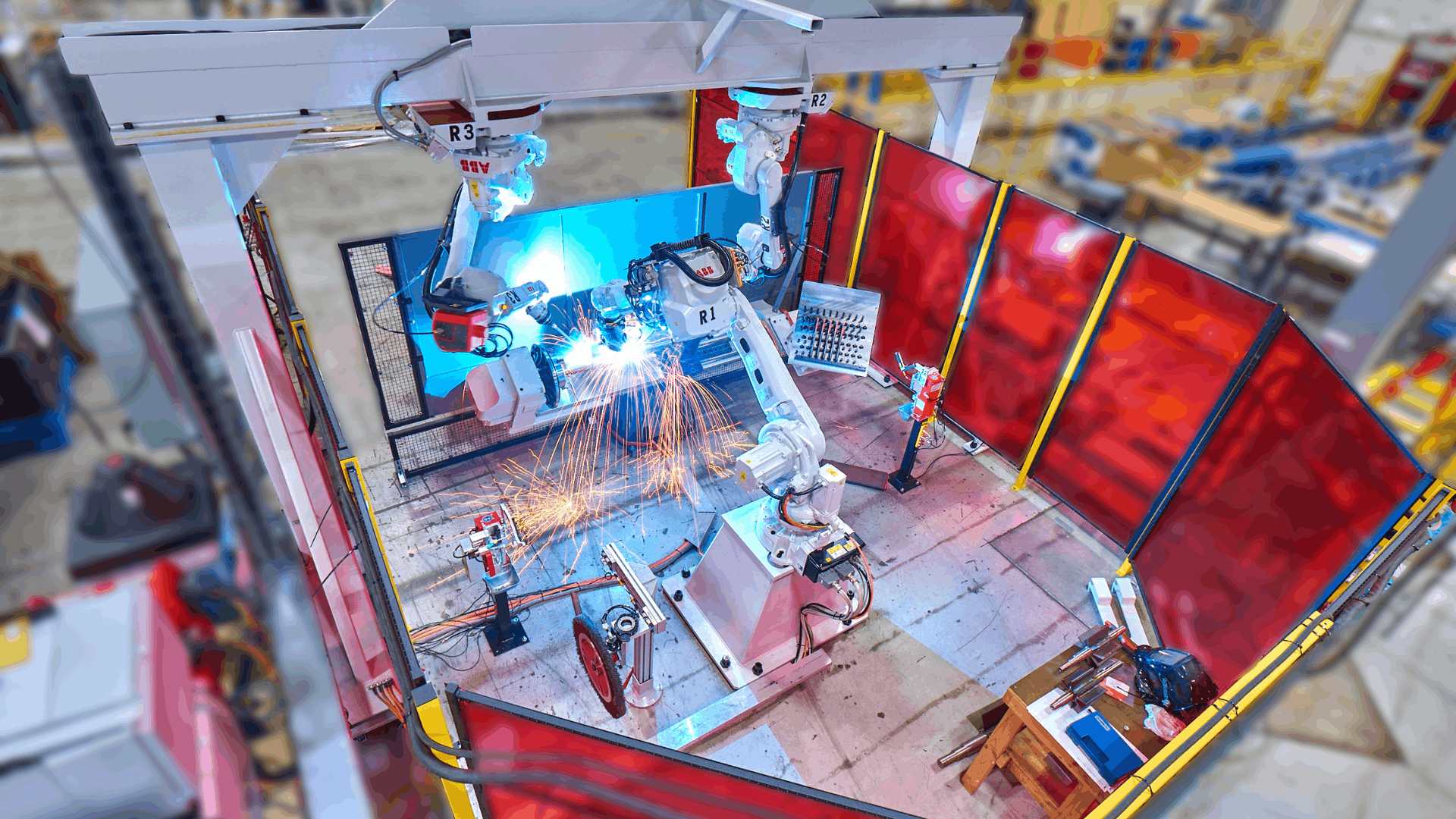

IRB4600 Robot on Riser with Laser Seam-Finding & Parametric Control

MWES delivered a turnkey cell featuring:

- ABB IRB4600 robot mounted on a riser to access all weld areas while transformer remains stationary

- Fronius TPS 5000 weld package with dual-wire feeders for switching between mild and stainless steel seamlessly

- Laser-guided seam finder to adapt welding paths based on actual seam locations

- Conveyor and light curtain centering system to position transformer within 1–2 in of accuracy

- Automatic torch maintenance routines integrated into the welding cycle

As part of process automation, the cell automatically selects torch programs based on transformer data and uses laser tracking to dynamically adjust for seam alignment—resulting in precise and efficient welding operations.

The Results

25-Minute Cycle Time with Enhanced Quality and Reduced Rework

The automation delivered:

- Fully robotic weld cycle time of approximately 25 minutes per transformer

- Elimination of manual welding inconsistencies and rework

- Improved first-pass weld quality and repeatability

- Seamless integration with upstream tack stations and downstream conveyor steps

By automating large-envelope welding with precision tracking and parametric control, the customer gained consistent quality, throughput reliability, and significant operator labor reduction.