EasyArc™ Cobot Weld Carts

Advantages to Cobot welding Carts

Boost Productivity

Automate Repetitive Tasks and Increase Throughput

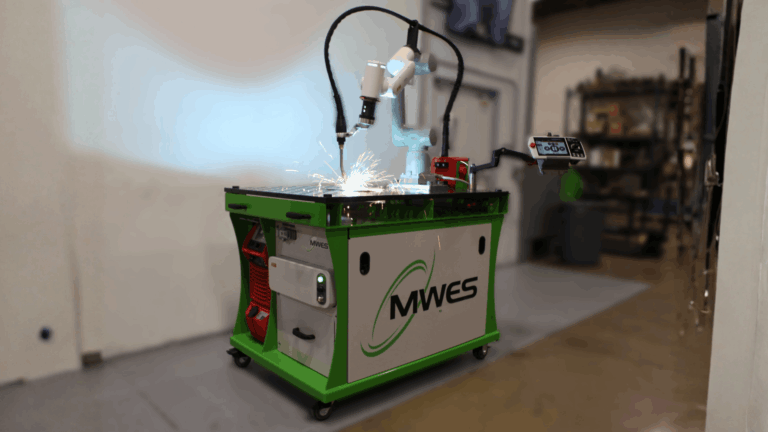

Collaborative robots can weld faster and more consistently than manual labor, dramatically reducing rework and increasing production uptime. Free up skilled welders for complex tasks while the cobot handles the routine, high-volume work.

Improve Weld Quality & Consistency

Deliver Repeatable, High-Precision Welds

Cobots maintain a consistent weld path every time, minimizing variation, improving joint strength, and ensuring quality across both short and long runs. Ideal for manufacturers seeking to minimize defects and meet stringent tolerance standards.

Easy to Program

User-Friendly Interface—No Coding Required

Teach new parts and weld paths quickly with drag-and-drop interfaces or by manually guiding the robot. Operators of all skill levels can deploy and adjust programs without advanced robotics experience—getting you up and running in less time.

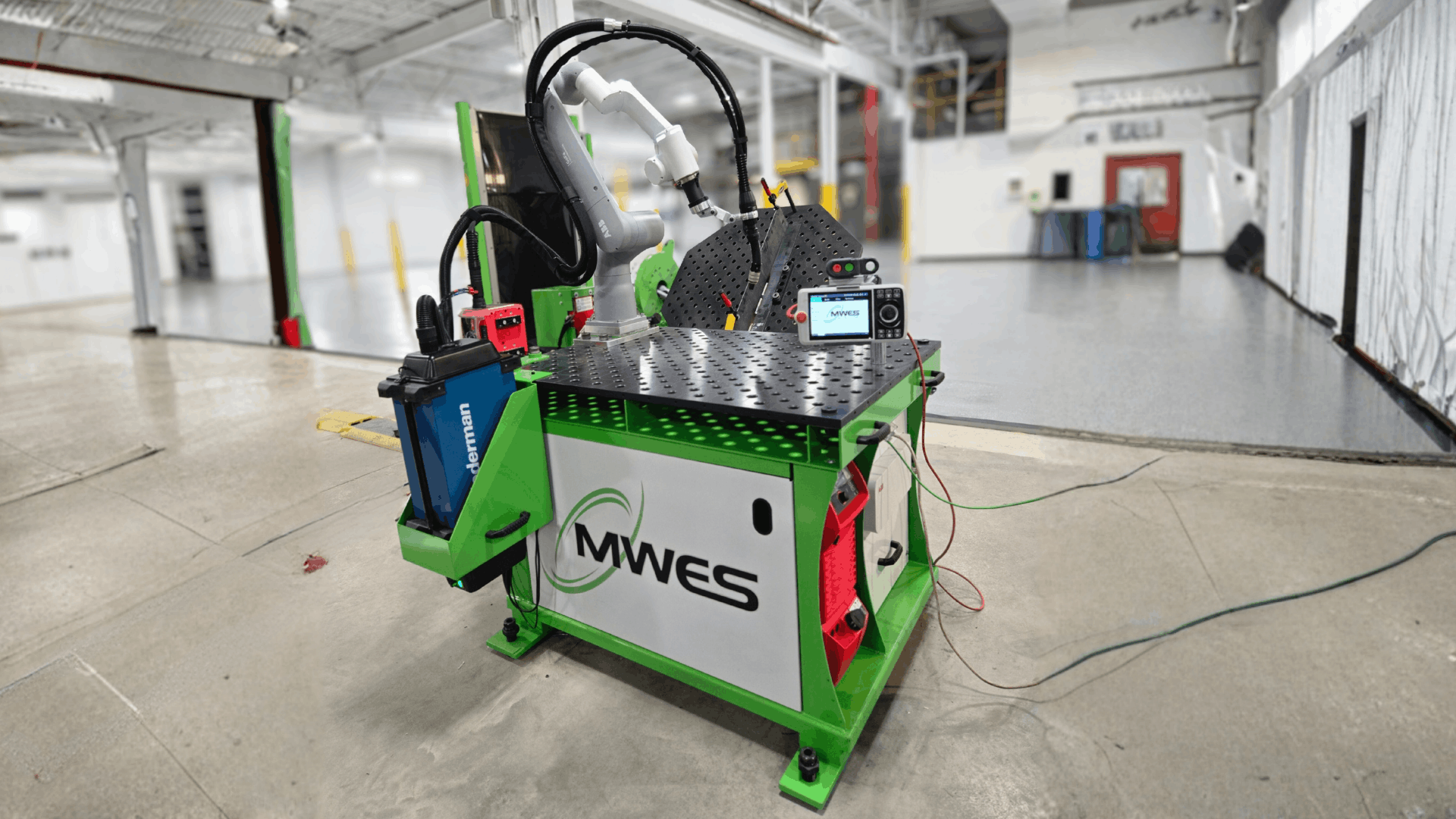

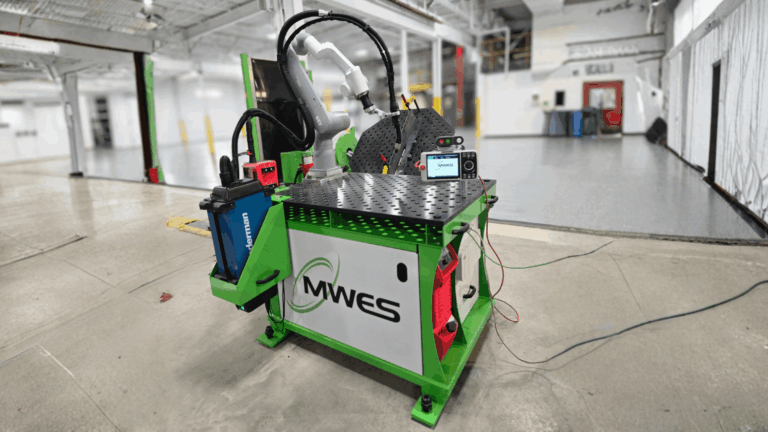

Harness collaborative robotic welding innovation with EasyARC by MWES. This entry‑level cobot welding cart delivers higher weld quality, lower downtime, and enhanced operator safety—without the need for cages or extensive floor modifications.

Simplify Welding with Automation

The EasyArc™ welding cart is a plug-and-play collaborative welding solution that combines ABB’s GoFaTM robot with Fronius® welding technology. Designed to complement skilled welders, this cart-based system makes it simple for any shop to automate welding tasks – without fences or complex programming.

Whether you’re entering automation for the first time or expanding your welding capabilities, EasyArc is built to get you up and running fast with consistent, high-quality results.

Standard System Specs

EasyArc Cart

- Powder-coated steel frame for durability & mobility

- Integrated wire spool holder

- Swing-arm mount for FlexPendant

- Houses both the controller and the welder in a compact layout

- Locking casters for easy repositioning on the shop floor

- Requires only one 480V 3-phase power drop

- Expandable control for future accessories or welding upgrades

- 1-year warranty included

ABB GoFa™ CRB 15000 Cobot

- Safe, rounded design with no pinch or trap points

- Safety certified to Category 3, PL d

- Up to 2.2 m/s TCP speed—faster than others in its class

- Integrated torque sensors for precise, safe motion control

- 1050mm reach—12% longer than comparable 5kg cobots

- Powered by ABB’s OmniCore controller for energy-efficient,

- high-performance motion (up to 20% energy savings)

- Optional upgrade to Long Arm Cobot with 10kg payload and

- 1.62m reach for larger parts and extended workspaces

Fronius TPS 320i Standard Welding Package

- 320A push system, water-cooled MIG welding package

- Innovative, user-friendly touch display

- Easily adaptable to individual welding needs & parameters

- Includes standard Fronius weld package for versatile applications

- Upgrade to 400A or 500A MIG welding capacity for heavy-duty applications

Bluco Modular Tabletop

- 1000mm x 1400mm workspace

- Precision modular fixturing system designed for robotic welding

- Achieves ±0.005” repeatability when paired with EasyArc cobot welding solutions

- Ideal for high-mix or precision applications requiring consistent setups

MWES EasyArc Software

- Weld Cart Controls

- Intuitive interface for fast part teaching and production setup

- No advanced programming skills required—ideal for all operator levels