The food industry faces unique challenges—labor shortages, high turnover, strict hygiene standards, and the need for consistent product quality. Collaborative robots (cobots) are transforming food production by automating repetitive tasks while working safely alongside human operators. Midwest Engineered Systems (MWES) provides custom cobot solutions designed specifically for the food and beverage sector to increase efficiency, reduce errors, and ensure food safety compliance.

The Challenge: Modern Food Production

Food manufacturers struggle with:

- Labor shortages that slow production

- Repetitive, physically demanding tasks causing ergonomic injuries

- Strict sanitary requirements that must be maintained at all times

- Variable product sizes and packaging formats that require flexibility

- High demand for fast, consistent output without sacrificing quality

Traditional manual processes are increasingly unsustainable in today’s competitive and fast-moving food market.

How Cobots Solve Food Industry Challenges

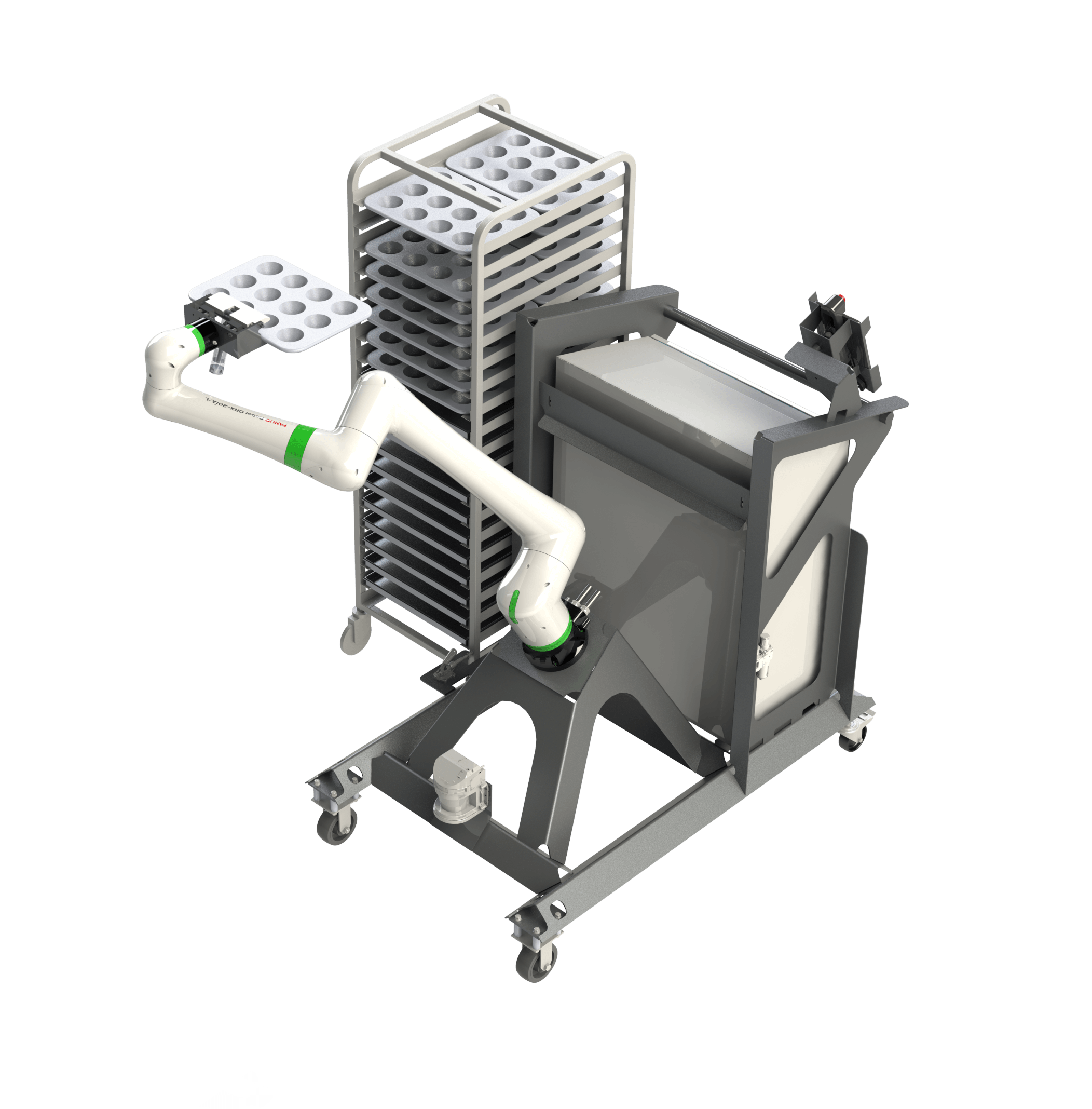

MWES integrates collaborative robots into food production lines, delivering solutions that enhance productivity and safety:

- Repetitive Task Automation: Cobots handle packaging, sorting, depanning, palletizing, and portioning—reducing fatigue and labor costs

- Safe Human Collaboration: Designed to work alongside employees without requiring extensive safety cages, following strict food-safe standards

- Flexible Programming: Quick recipe changes allow cobots to handle different products, packaging sizes, or batch runs

- Hygienic Design: Stainless-steel frames and smooth surfaces for easy cleaning and sanitation

- Integration with Existing Equipment: Cobots seamlessly work with conveyors, ovens, and packaging machines to maintain continuous flow

By leveraging cobots, food manufacturers increase throughput, maintain consistency, and protect workers from repetitive strain injuries.

Benefits of Cobots in Food Applications

- Increase Production Efficiency: Automate repetitive tasks while maintaining fast cycle times

- Ensure Product Consistency: Repeatable, precise movements reduce errors and waste

- Improve Worker Safety: Cobots handle heavy, repetitive, or ergonomically challenging tasks

- Enhance Flexibility: Easily adapt to new products, packaging, or recipes

- Maintain Food Safety Standards: Cleanable, hygienic designs meet strict regulatory requirements

Applications of Food Industry Cobots

MWES cobots are used across baking, confectionery, dairy, beverage, frozen foods, and ready-to-eat operations for tasks such as:

- Rack loading and unloading

- Depanning and portioning

- Packaging and labeling

- Palletizing and depalletizing

- Sorting and quality inspection

Each solution is custom-engineered to fit your line layout, product type, and production goals.