The Challenge

Precision Spot Welding With Minimal Labor Dependency

This manufacturer needed a repeatable spot welding process but lacked the skilled labor to execute it manually. Their goals included:

- Automating spot welding for left- and right-hand fork tube covers

- Eliminating the need for skilled welders in this stage of production

- Creating a system that’s safe and easy for a single operator to run

- Simplifying machine controls for minimal operator training

MWES was chosen to deliver a compact, intuitive welding machine that would meet quality standards while reducing labor dependency.

The Solution

Single-Operator Spot Welding Cell With Configurable Fixturing

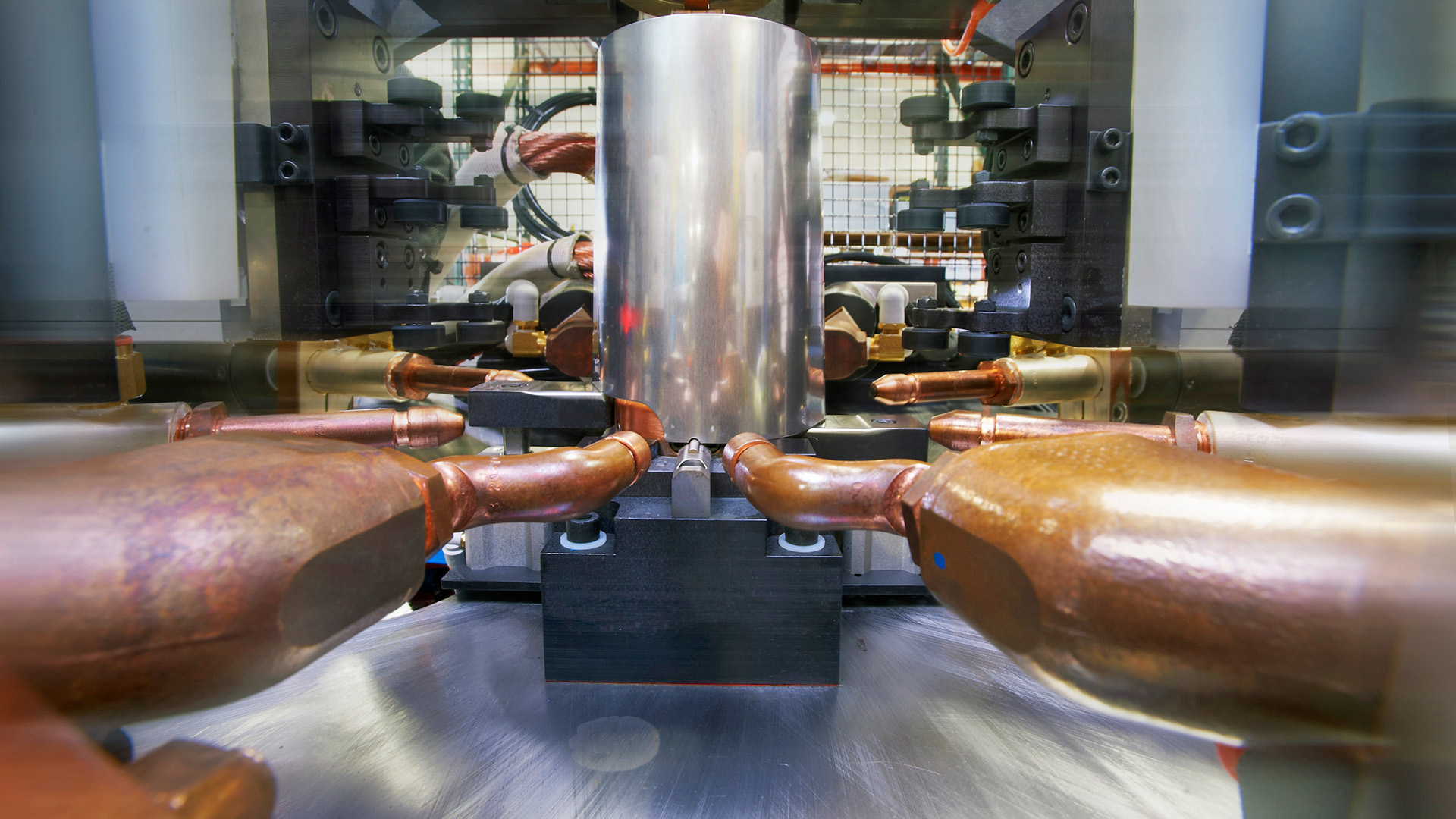

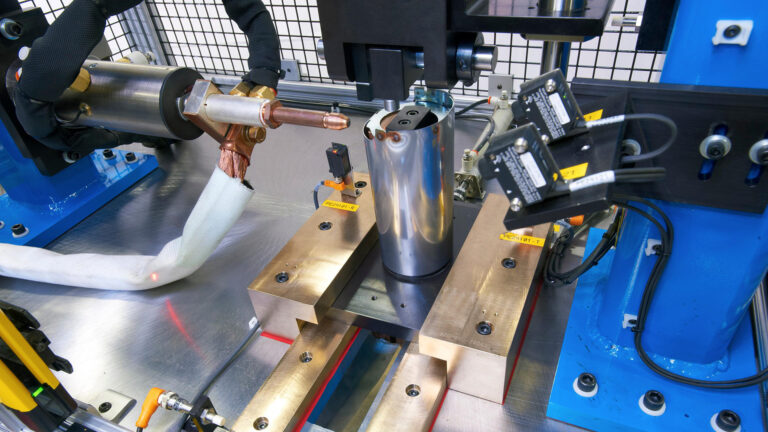

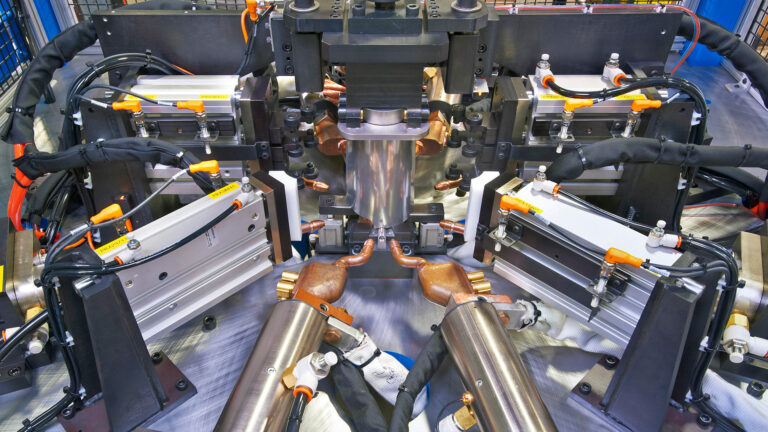

MWES designed a self-contained automated spot welding system capable of welding both left- and right-hand versions of the fork tube covers. Key system features included:

- Pneumatically actuated tooling to clamp and support the can and wrapper

- Eight weld cylinders performing sequential welds in two separate sets

- Configurable engagement based on part orientation (LH or RH)

- Seam welding system that slides and performs multiple welds automatically

The operator simply loads the parts, presses start on the HMI, and removes the completed assembly—achieving safe, repeatable results with minimal input.

The Results

Consistent Welds, Simplified Operation, and Labor Efficiency

The automated welding system delivered the following benefits:

- Enabled consistent and accurate spot welds on both part variants

- Reduced labor requirements to a single operator per shift

- Improved safety with fully enclosed fixturing and hands-free welding

- Simplified operations with intuitive HMI control and fast training curve

By automating a critical assembly task, MWES empowered this customer to scale production efficiently while maintaining high quality standards.