The Challenge

Eliminating Labor Constraints in High-Volume Track Seal Production

Manual assembly of track cans and lips was labor‑intensive and limited scale. The customer needed to:

- Rapidly assemble track seal parts at high volume

- Ensure precision fitting of polycarbonate components

- Include part inspection to catch defects in real time

- Reduce reliance on manual labor amid tight labor markets

MWES was selected to deliver a turnkey robotic cell capable of inspection-integrated assembly and end-of-line packaging.

The Solution

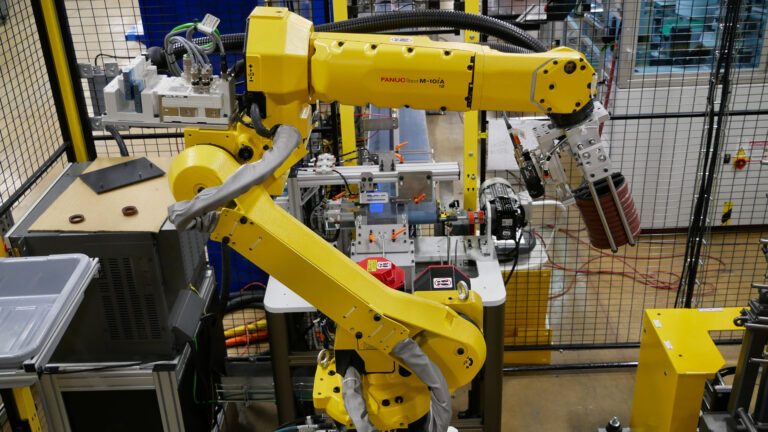

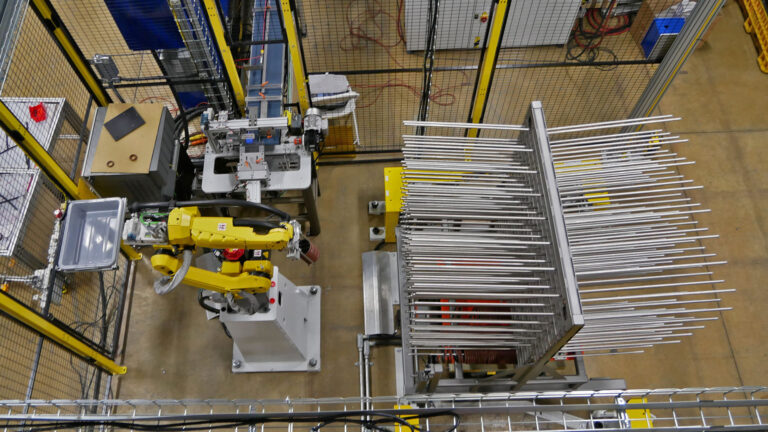

Integrated Vision Inspection & Assembly Robot Cell Feeding Packaging Station

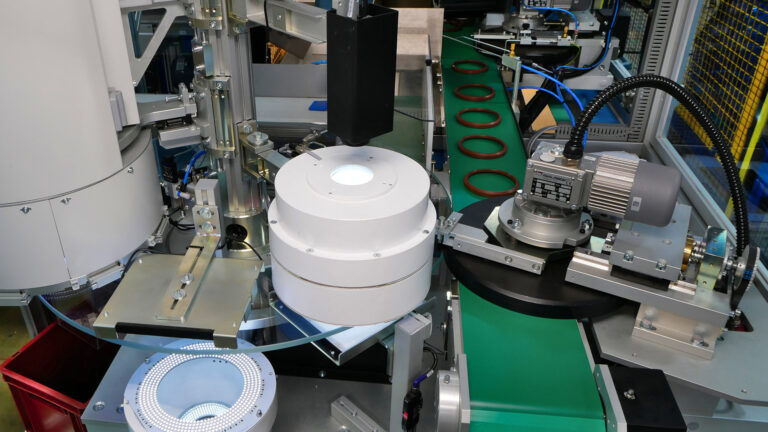

MWES engineered a fully automated system featuring:

- Bulk feeders and bowl hoppers for cans, lips, and rings

- Dial table staging parts for sequential inspection via cameras and laser sensors

- Vision-guided robotics assembling components after passing quality checks

- Synchronized conveyors and order-specific packaging flow

This turnkey assembly cell automates inspection, component mating, and packaging in a continuous flow—requiring minimal operator intervention and eliminating manual reject sorting.

The Results

Higher Throughput, Consistent Quality, and Reduced Labor Dependency

Implementation of this automated line delivered key benefits:

- Achieved fast assembly and packaging throughput for track seals

- Ensured consistent part quality by catching defects early via inspection station

- Reduced manual labor and eliminated reliance on multiple assembly workers

- Enabled stable production flow with minimal handling and high yield

By merging automated vision inspection with robust assembly and packaging automation, MWES helped the customer scale track seal production with improved accuracy, speed, and worker safety.