The Challenge

Repositioning Heavy Weldments Without a Crane

The manufacturer previously relied on overhead cranes and manual repositioning to weld large parts—a method that was slow, inconsistent, and posed safety risks. They needed a durable device capable of:

- Handling parts between 600–1,000 lbs reliably

- Providing full 360° rotation and part access without crane use

- Coordinating part motion with robotic welding

- Ensuring safer, faster weld positioning compared to manual handling

MWES was selected to design a high-capacity positioner that would eliminate crane use and operator repositioning.

The Solution

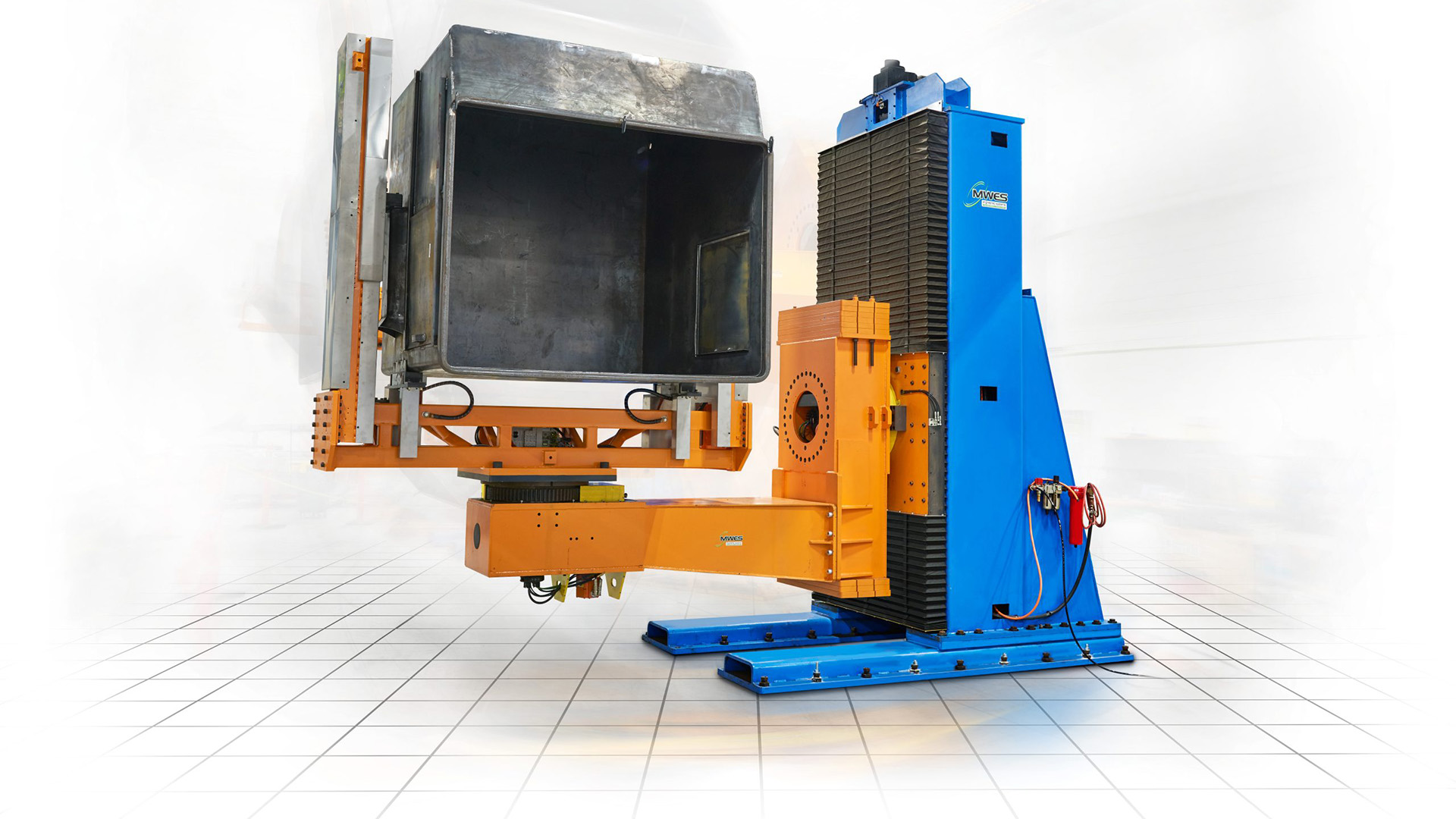

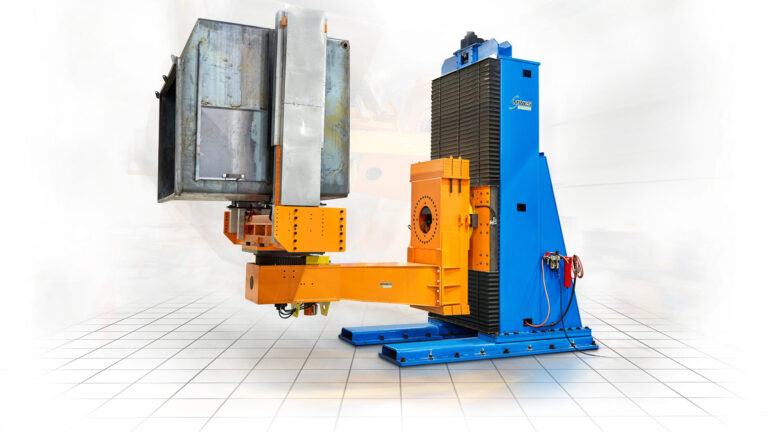

Skylift 3‑Axis Servo Positioner with Robotic Integration

MWES engineered and deployed a floor-mounted Skylift positioner featuring:

- Up to 8,000 lb payload capacity on the platter axis

- Up to 60 in of vertical lift travel and 180° arm rotation combined with continuous platter rotation

- Integrated auxiliary axis control for a welding robot, enabling coordinated motion with the part

- Through-center routing of cabling and tubing for optimal movement reliability

This positioner eliminated the need for overhead cranes, enabling safe and precise part manipulation for robotic welding. In summary, the Skylift offers flexible, high-capacity orientation of heavy weldments—enabling weld-quality improvement and operator safety.

The Results

Faster Setup, Greater Safety, and Weld Consistency Without Crane Use

The implemented positioner cell delivered immediate benefits:

- Eliminated overhead crane usage and associated safety risks

- Cut material handling time in half and improved cycle speed

- Enabled consistent part orientation for cleaner, repeatable welds

- Removed operator lift certification requirements and avoided hoist-related ergonomics

By integrating this standard Skyhook positioner, MWES helped the customer boost welding throughput, reduce labor complexity, and improve quality—all with safer, more ergonomic operations.