The Challenge

Automating Complex Rotor Welding with Precision and Consistency

Welding multi-vane rotor assemblies presented significant challenges due to part size, geometry, and quality requirements. The existing manual welding process was labor-intensive and difficult to standardize, resulting in variability and inefficiencies.

Key challenges included:

- Complex geometries requiring multi-axis positioning for precise weld placement.

- Consistency issues due to variations in manual welding techniques.

- High labor costs and difficulty finding skilled welders.

- Integration with existing fixtures and workflow to minimize downtime.

The customer required a robotic welding solution capable of delivering repeatable, high-strength welds while improving productivity, safety, and overall process control.

The Solution

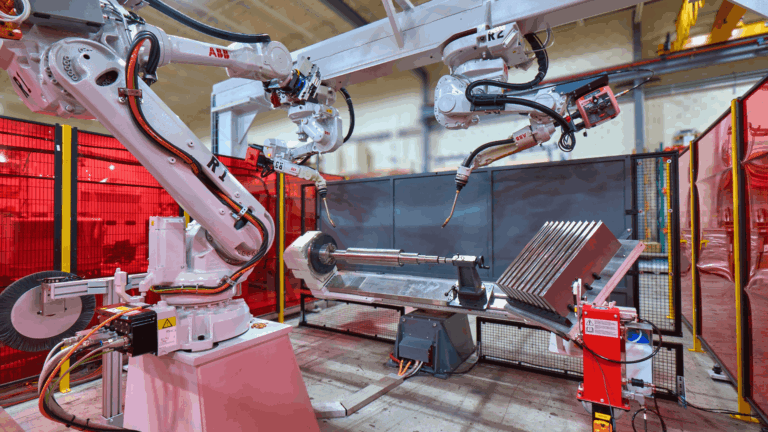

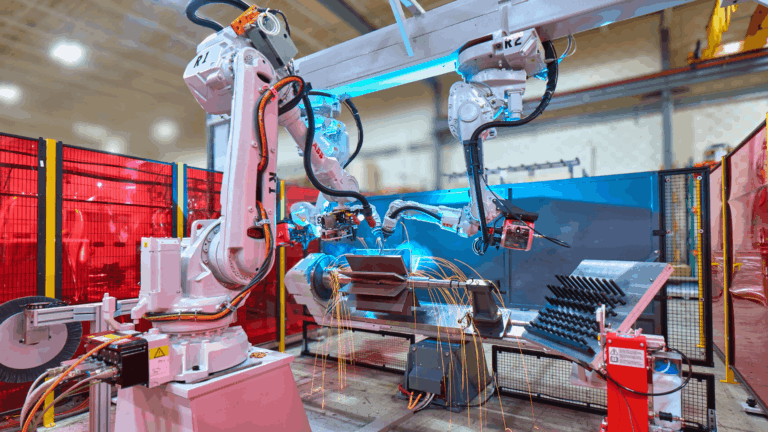

Servo-Tracked Robotic Welding Cell with Multi-Axis Part Manipulation

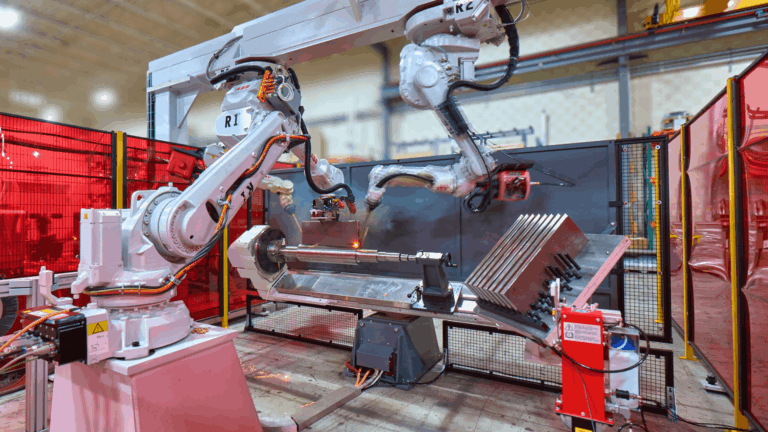

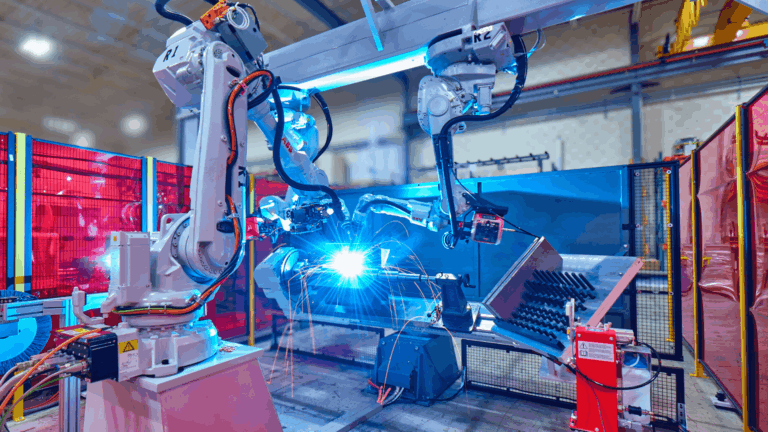

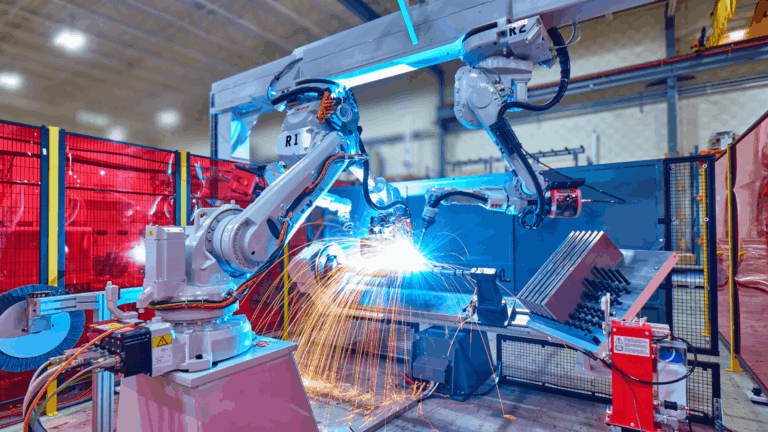

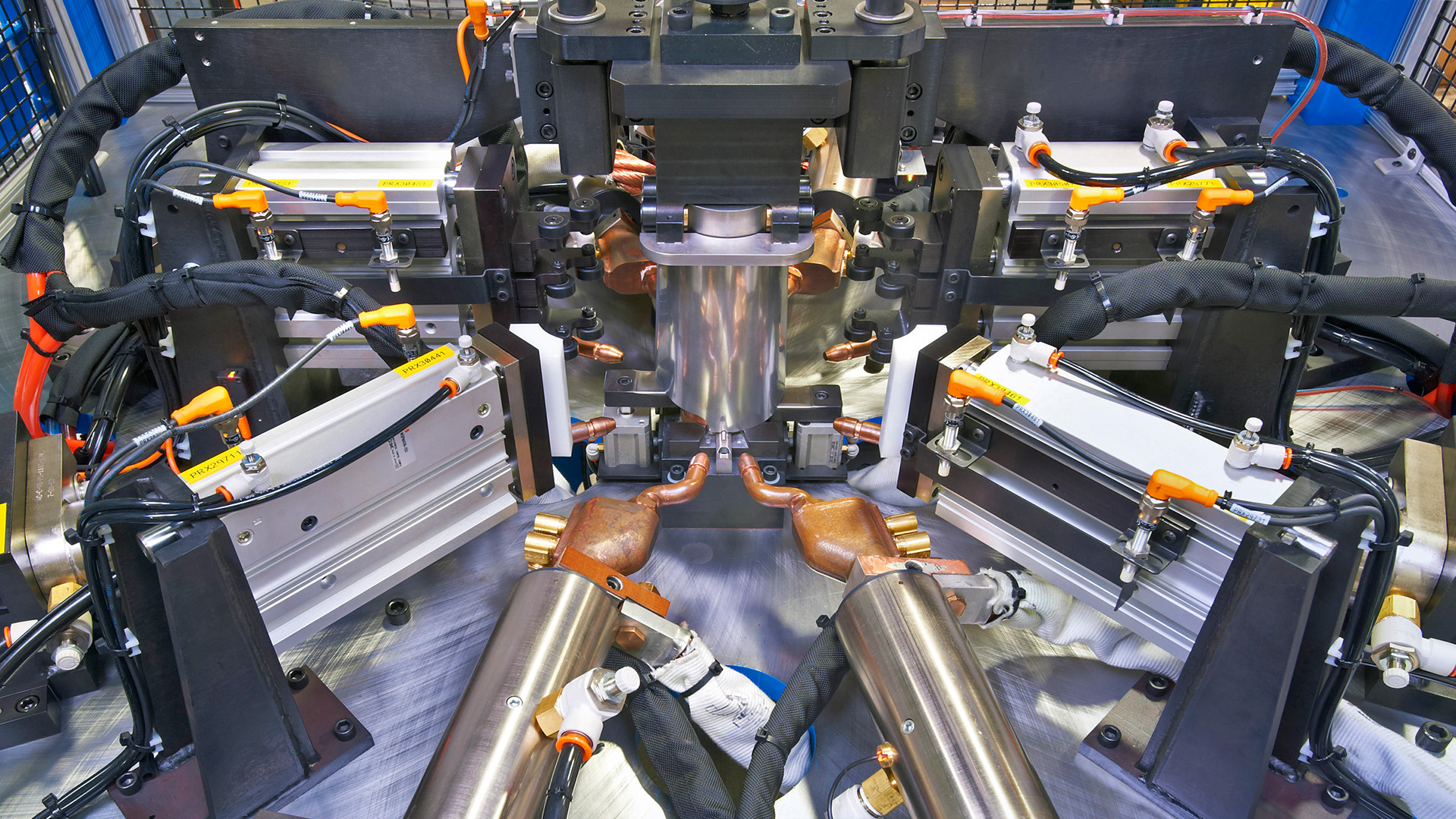

MWES designed a custom robotic welding cell built around an ABB IRB 800 industrial robot mounted on a servo-driven track, providing extended reach across large rotor assemblies. Dual-axis servo positioners precisely manipulate each part, ensuring optimal weld angles and consistent penetration at every joint.

Key system features include

- Dual-Axis Servo-Driven Positioner – Fully manipulates the part for optimal weld angles.

- Precision MIG Welding System – Ensures consistent, high-strength welds across all joints.

- Advanced Safety Features – Including light curtains, operator load stations, and interlocked access points.

- HMI Interface – Allows operators to load part programs, verify components, and monitor cycle progress.

- Integration with Existing Equipment – Designed to work with the customer’s current handling and inspection systems.

Once the part is loaded and verified via sensors, the system automatically executes the full weld sequence—coordinating robot motion, part positioning, and weld parameters for consistent results across every assembly.

The Results

High-Quality, Repeatable Welding with Reduced Labor and Faster ROI

Implementation of the custom robotic welding solution delivered measurable operational improvements:

- Up to 40% Increase in Throughput through consistent, automated cycle times

- Significant reduction in scrap and rework due to improved weld consistency

- Lower Labor Dependence, with a single operator overseeing the entire process

- Improved Workplace Safety by minimizing exposure to heat, fumes, and repetitive strain

- Rapid ROI driven by labor savings, reduced variability, and increased production capacity

By integrating servo-controlled robotics, advanced positioning, and safety systems into a single turnkey solution, MWES delivered a robust welding automation platform capable of meeting strict industrial and aerospace manufacturing standards.