The Challenge

Balancing Quality, Flexibility & Safety in Heavy-Part Bending Operations

For this leading fabricator, the need for repeatable, high-quality output was matched only by the demand for flexibility and safe handling of large, heavy parts in a high-mix environment.

- Required a system capable of bending a wide variety of metal parts

- Needed to accommodate part weights exceeding 500 lbs

- Required precision multi-bend operations on single parts

- Needed to reduce physical strain and safety risks for operators

MWES was selected for its expertise in developing safe, flexible, and high-performance robotic machine tending systems that can adapt to complex forming requirements.

This project demanded a robust, intelligent automation system capable of transforming a labor-intensive process into a scalable, repeatable, and safe operation.

The Solution

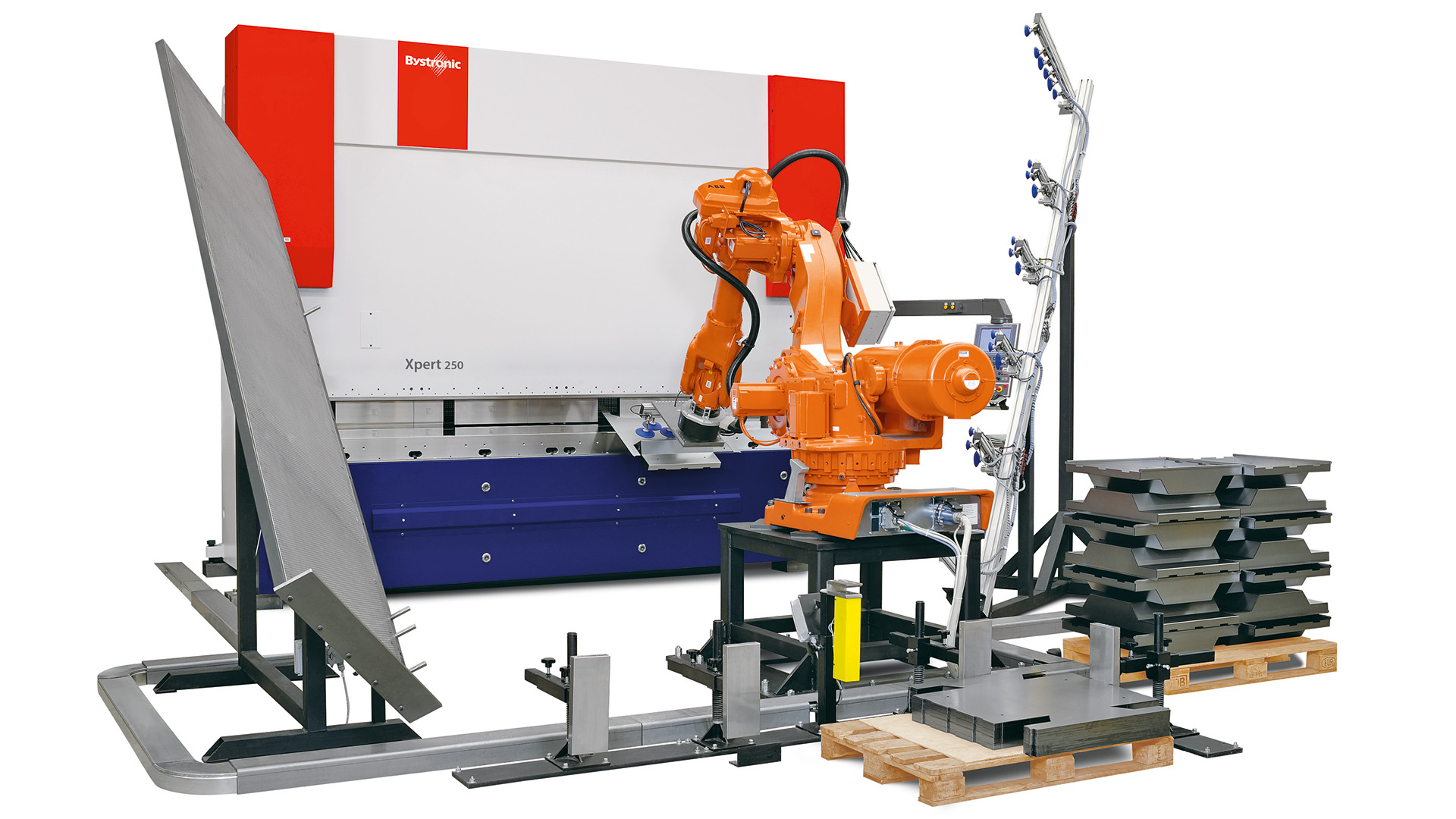

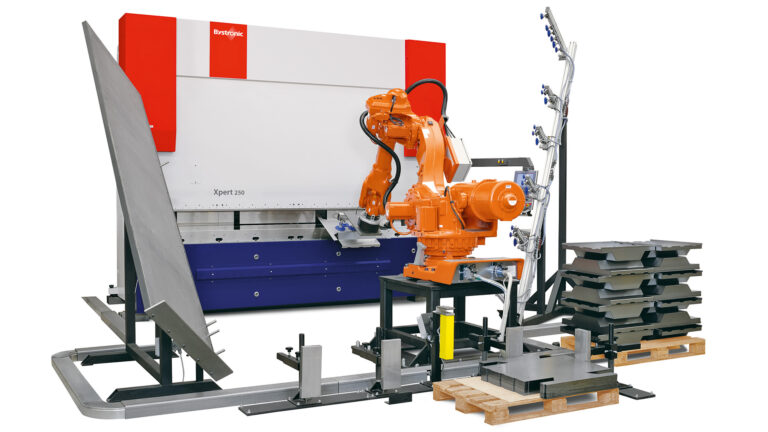

Robotic Press Brake Work Cell with Smart Handling & Flexibility

MWES delivered a fully automated press brake cell featuring a multi-tool robot, advanced part-handling fixtures, and intuitive operator controls—engineered for both power and precision.

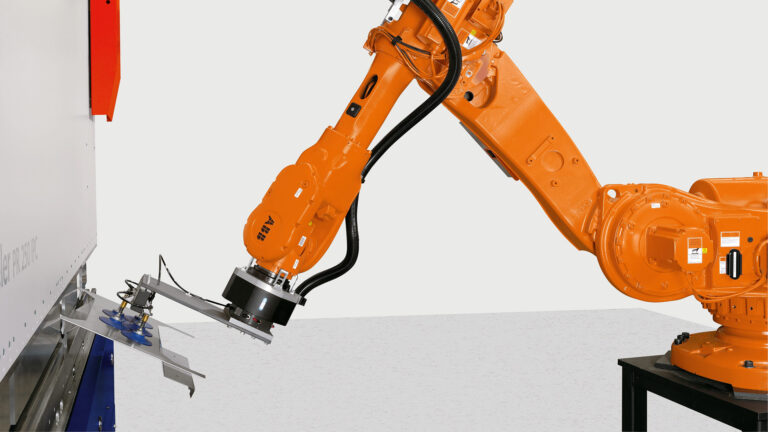

- Integrated ABB robot with 3 automatic end-of-arm tooling changers

- Custom squaring station and re-grip unit for precise part alignment

- Bystronic Xpert 250 press brake integrated with BendWare programming

- Forklift-loadable infeed station and operator-accessible outfeed zone

With intuitive operation via the IRC5 FlexPendent, the system enables seamless loading, bending, and unloading. Regrip capabilities ensure exact positioning for multiple bends, even on complex geometries.

Designed for minimal operator involvement and maximum repeatability, the system keeps the process efficient, ergonomic, and consistent.

The Results

Increased Productivity, Better Quality & Safer Working Conditions

MWES’s solution delivered measurable improvements in throughput, safety, and part quality—transforming the manufacturer’s forming capabilities.

- Boosted productivity with fully automated multi-bend workflows

- Minimized manual lifting of 500+ lb parts, enhancing worker safety

- Reduced part-to-part quality variation through precision handling

- Enabled remote system access for better process control & oversight

This flexible press brake automation system has elevated both operator experience and manufacturing consistency—unlocking greater capacity and capability for the customer’s future operations.