The Challenge

Reducing Risk While Maintaining Throughput in Extreme Heat

Manual labor in high-temperature environments presents critical safety risks and workforce challenges. This customer needed a robotic solution to:

- Eliminate worker exposure to hazardous furnace conditions

- Load and unload dual 36″ steel shafts with precision

- Automate processing across furnace, quench, and temper lines

- Operate continuously with minimal human involvement

They needed an experienced partner to engineer a robust, multi-station automation cell built for their demanding foundry environment—and MWES delivered.

The Solution

Track-Mounted Robotic Cell Integrates Furnace, Quench, and Temper Stations

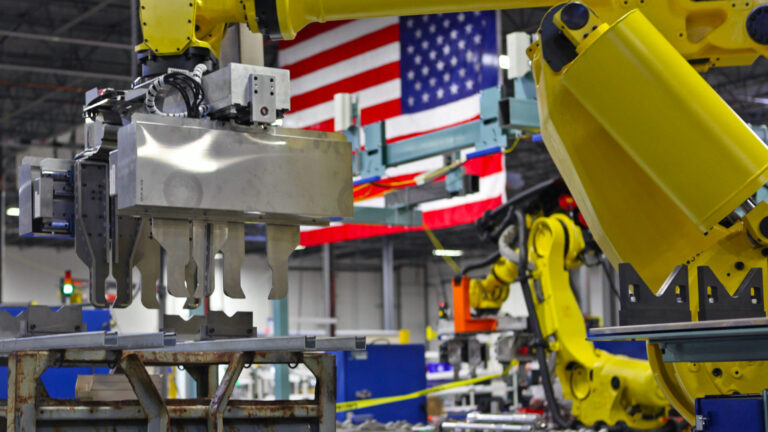

MWES designed and installed a fully integrated robotic system featuring two Fanuc industrial robots—one stationary and one track-mounted—to handle the entire shaft heat-treatment process from infeed to final cooling.

- Fanuc R-2000iB/210F: Stationary robot for furnace loading

- Fanuc R-900iA/350: Floortrack-mounted robot handles transfers to quench and temper stations

- Custom EOAT: Gripper automatically adjusts to shaft width based on HMI part number input

- Full System Integration: Includes infeed conveyor, v-block cooling, and forced-air cooling for safe handling

- Straightener Integration: Supports additional shaft processing between tempering and final coolin

This turnkey solution streamlined the entire shaft processing operation, significantly reducing manual intervention in hazardous zones.

The Results

Enhanced Worker Safety and Streamlined Multi-Station Heat Treating

The installed robotic cell transformed a dangerous, labor-intensive process into a streamlined, fully automated operation. Key outcomes included:

- Reduced safety risks by eliminating operator exposure to extreme heat

- Achieved consistent robot load rates of <90 seconds per shaft

- Enabled consistent, hands-free handling of variable shaft sizes

- Improved process consistency across quench and temper stages

- Reduced labor dependency for a hard-to-fill operational role

By automating this hazardous application, MWES helped the customer improve worker safety, streamline multi-step processes, and reduce operational liability.