The Challenge

Skilled Welder Shortage Impacting Production Capacity

Facing labor constraints and the rising costs of certified welders, the manufacturer needed a reliable automated solution that could maintain welding quality and scale with production demand.

- Limited availability of trained welders

- Increasing labor costs threatened profitability

- Manual welding introduced variability in quality

- Production needed to scale without expanding workforce

MWES was selected for its ability to deliver a reliable, cost-effective robotic welding cell that could integrate seamlessly with the customer’s production process.

The Solution

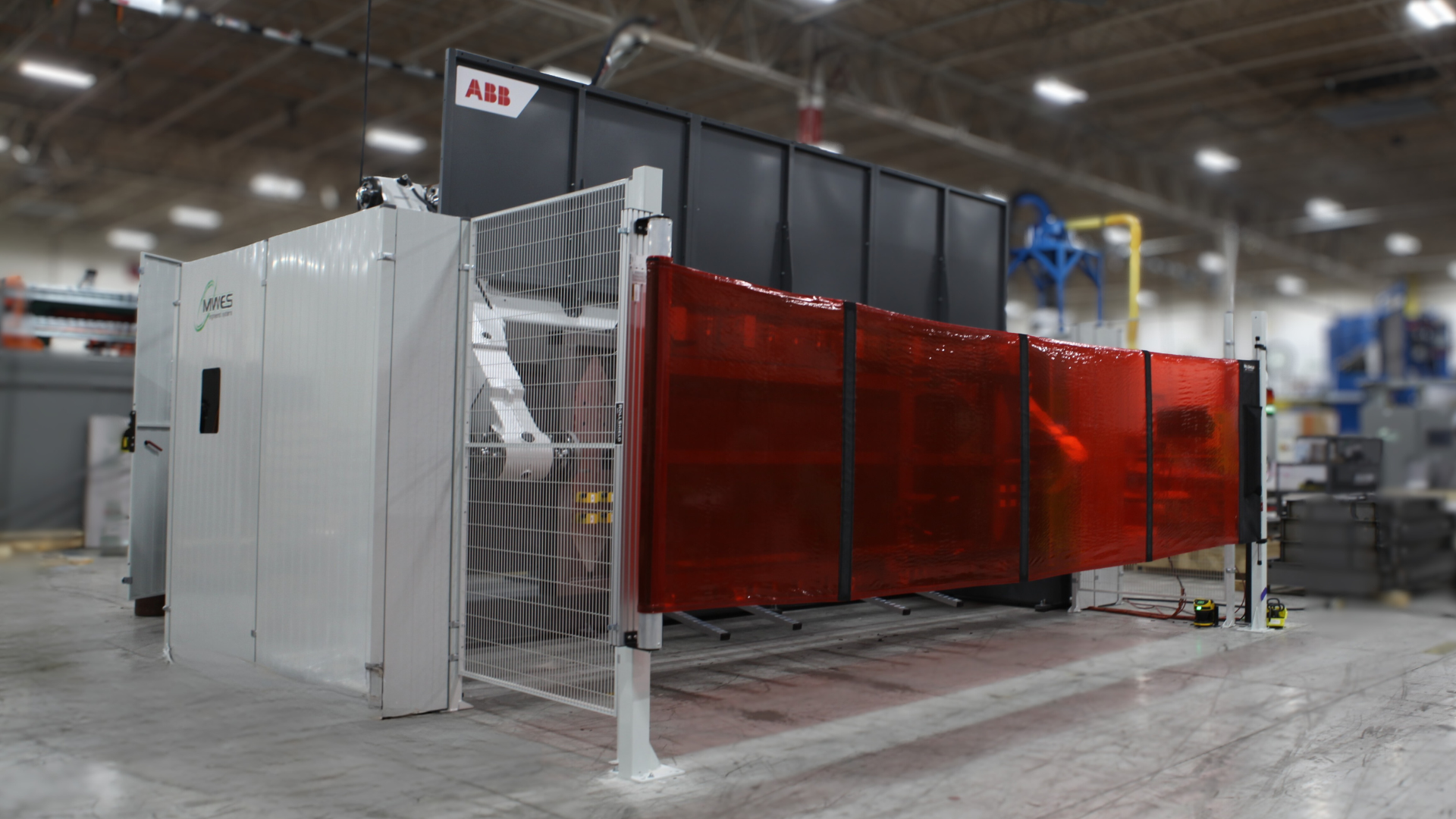

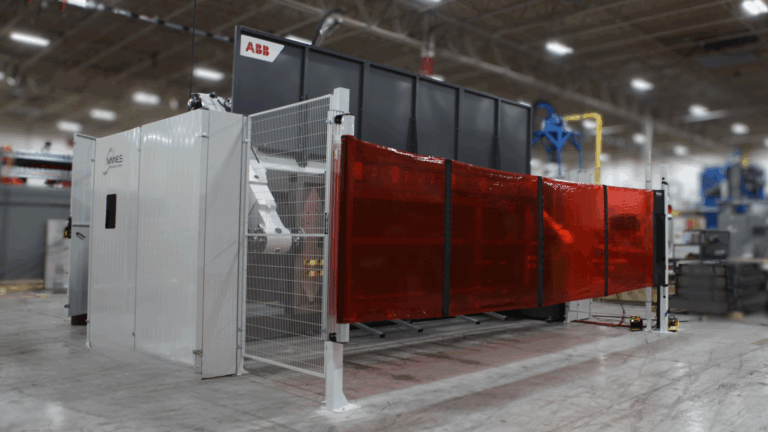

Standard Ferris Wheel Welding Cell with Custom Fixturing

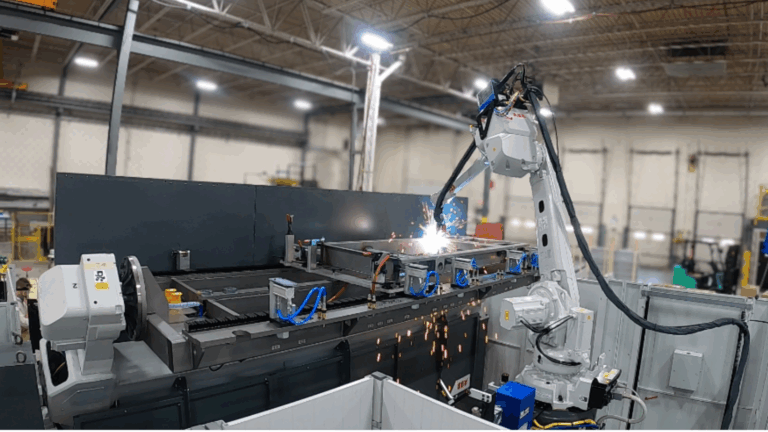

MWES engineered and installed a Standard Ferris Wheel Welding Cell featuring a 2-sided positioner, industrial robotic welder, and barcode-based part recognition system for seamless operator interaction.

- 2-sided Ferris wheel positioner enables continuous load/unload cycles

- Barcode scanner triggers robot to call correct welding program

- Custom fixturing ensures consistent part positioning and weld quality

- Integrated operator workflow allows for safe tack welding and system prep

This semi-automated system enables parallel processing—robot welding on one side while the operator loads and preps the next part on the other—drastically reducing downtime.

The Results

Higher Throughput, Lower Rework, and Safer Operations

The automated welding cell provided measurable improvements in operational efficiency, safety, and product quality.

- Doubled throughput compared to manual welding processes

- Reduced rework and increased part consistency through precision robotic control

- Lowered injury risk and operator fatigue by minimizing manual weld exposure

- Maximized uptime through efficient part handoff between operator and robot

By automating the welding of large base frames, MWES helped the customer meet growing demand without expanding their workforce or sacrificing quality.