The Challenge

Manual Deburring Was Labor-Intensive, Inconsistent, and Unsafe

To meet growing production demands and improve safety, the customer needed a more efficient, reliable, and less labor-dependent method of deburring large, heavy-duty engine blocks.

Post-processing massive 3500 hp industrial engine blocks is both labor-intensive and hazardous. Manual deburring and polishing require a large workforce and still result in inconsistent finishes. To improve throughput, consistency, and worker safety, this manufacturer sought to fully automate the deburring process with minimal operator involvement.

- Required a scalable, high-throughput alternative to manual deburring

- Needed to reduce worker exposure to hazardous, high-effort post-processing

- Aimed to improve consistency across large, complex engine blocks

- Desired reduced cycle time without sacrificing quality

By automating this task, the customer aimed to improve output, reduce labor strain, and ensure repeatable quality at scale.

The Solution

Dual-Robot Automation for High-Speed, Precision Deburring

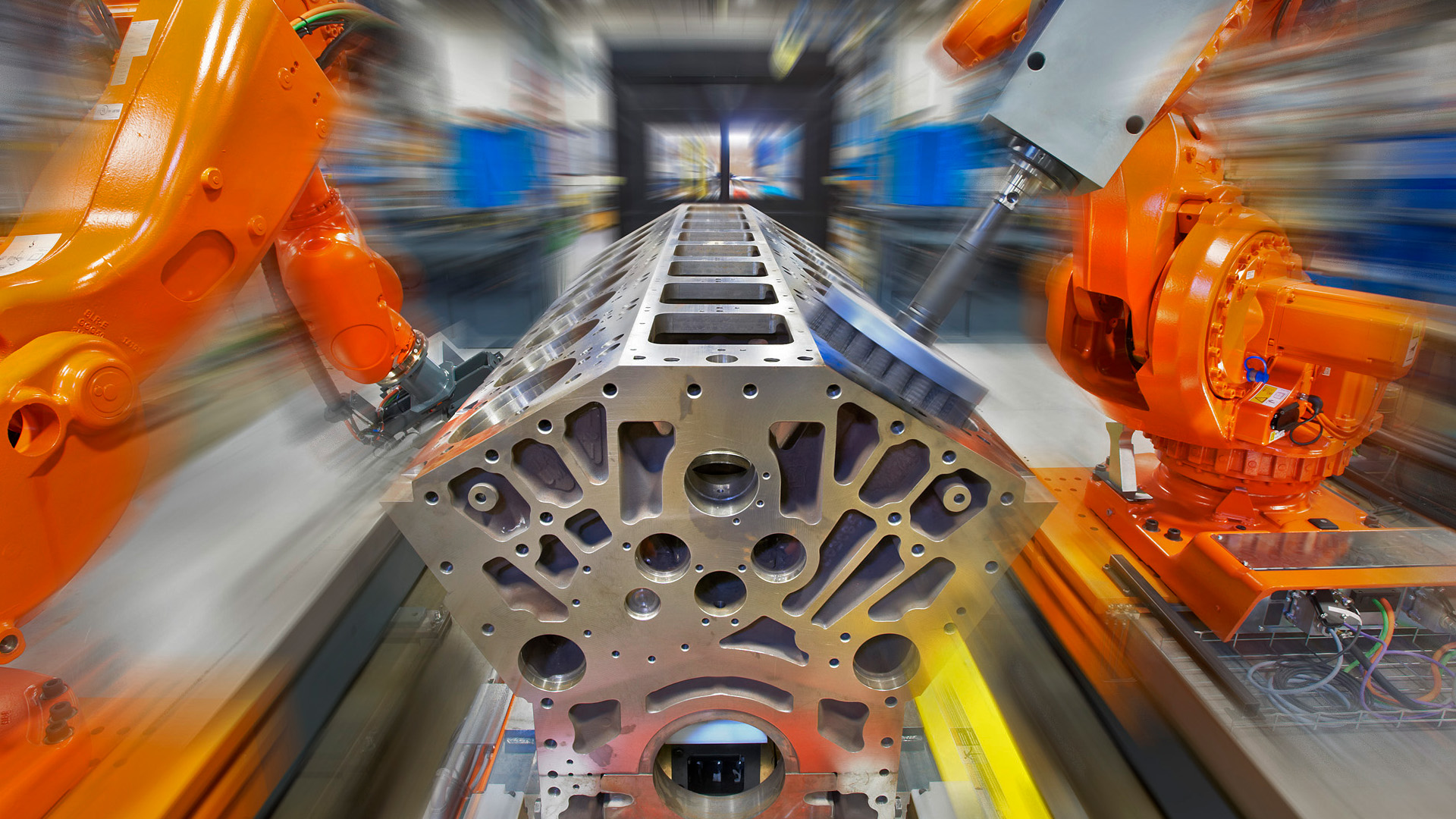

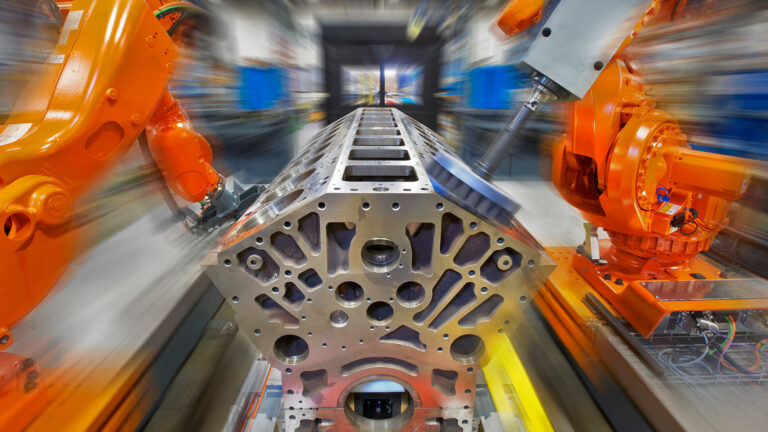

MWES engineered two fully automated deburring and polishing systems tailored to the customer’s specific engine block production process. Each system includes two track-mounted ABB robots equipped with advanced sensing and deburring tools.

- Dual-robot system with track-mounted ABB robots working in unison on either side of each block

- Automated conveyor systems move engine blocks through enclosed deburring and inspection zones

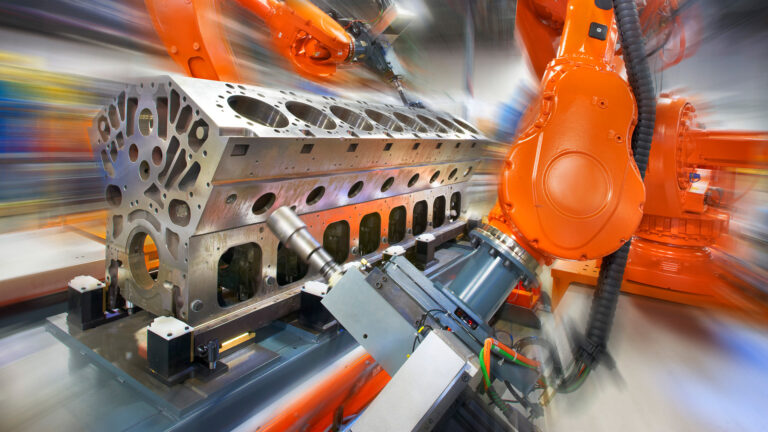

- High-performance deburring/polishing spindles with 10 hp servo control for a wide range of tools

- RFID-equipped tool change stations for seamless, intelligent tool switching with real-time wear detection

By combining advanced sensing and automation, MWES delivered a turnkey system that handled complex part geometries and minimized operator input.

The Results

High Throughput and Reduced Manual Labor Risks

The completed automation solution dramatically improved the customer’s production performance while enhancing workplace safety and operational efficiency.

- Increased finished engine block output to 14–16 per day

- Reduced deburring cycle time from 4 hours to 20 minutes

- Lowered operator involvement from 8 hours to just 2

- Removed workers from high-risk grinding environments

MWES’s automated system helped the customer scale production while improving consistency, safety, and cost-efficiency.