The Challenge

Manual Packing & Palletizing Was Slow, Labor-Intensive, and Inconsistent

The customer needed a scalable, flexible automation solution to replace heavy manual labor in case handling:

- Automatically erect and seal cases using pre-glued RSC cartons

- Pack product parts into boxes with bubble wrap and instruction sheets

- Handle multiple case sizes and product types without downtime

- Interface seamlessly with existing pallet stuffing and staging areas

MWES was selected for its ability to deliver a fully integrated, modular packaging and palletizing solution with minimal staffing requirements. YouTube+5Midwest Engineered Systems+5Midwest Engineered Systems+5Midwest Engineered Systems+1Midwest Engineered Systems+3Kawasaki Robotics+3Midwest Engineered Systems+3

The Solution

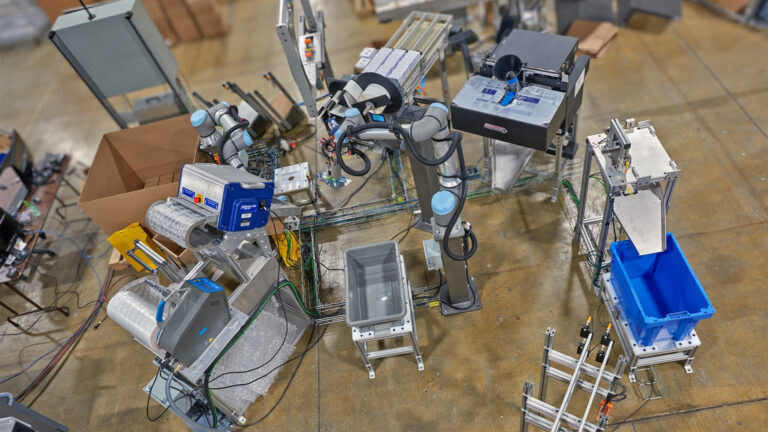

Two‑Cobot Packaging Cell Integrated with Labeling & Palletizing Automation

MWES provided a streamlined robotic packaging and palletizing solution featuring:

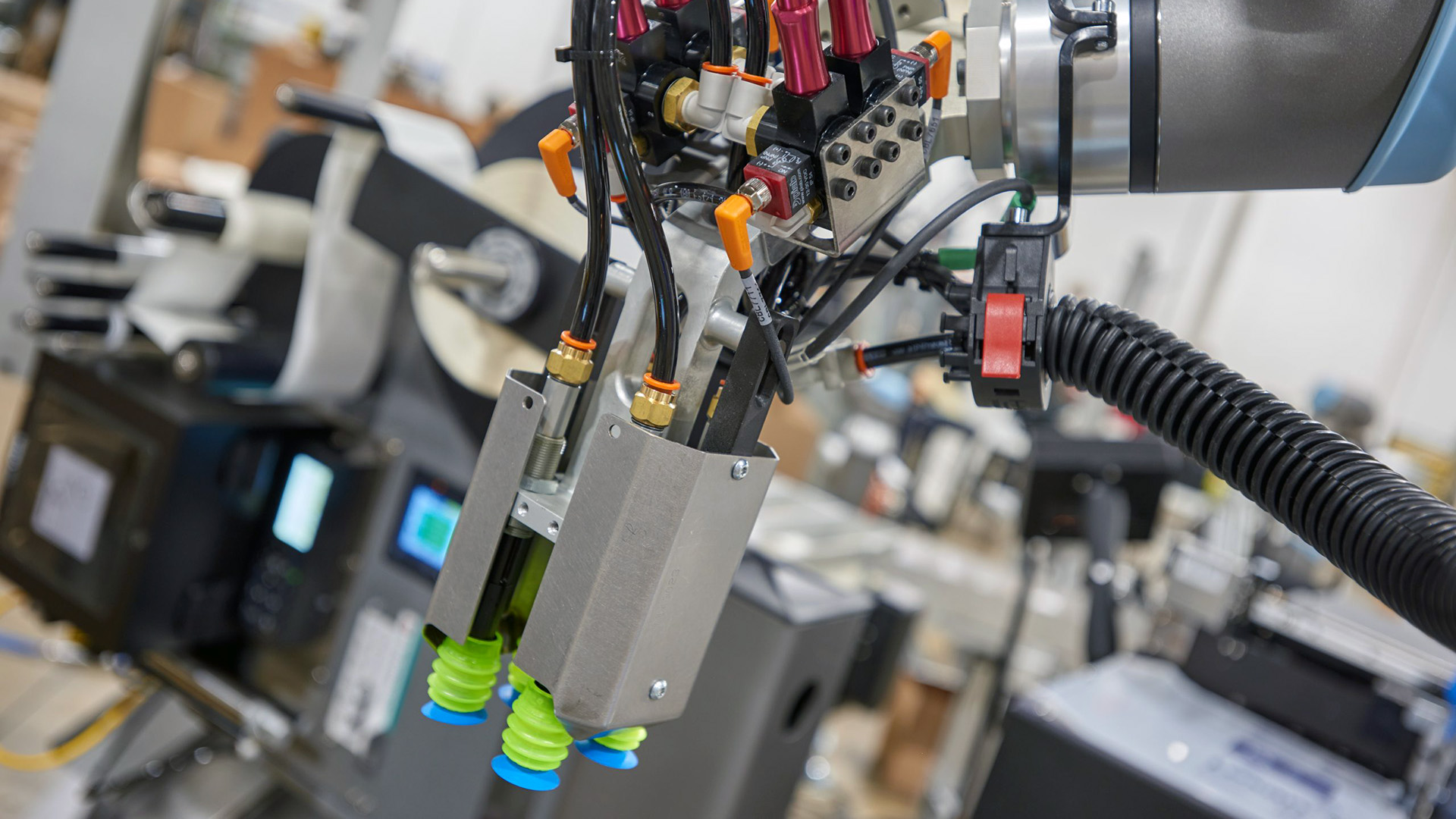

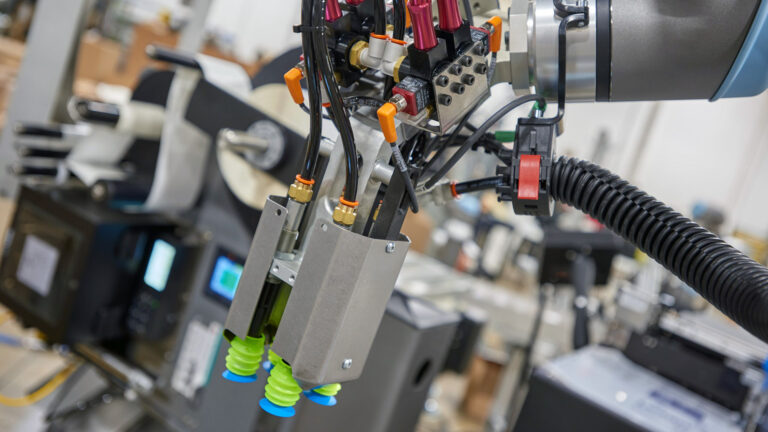

- Dual Universal Robots (UR10e): one for box erection and sealing, one for part insertion and finalization

- Integrated carrier disassembly, manual insertion, and label print-and-apply stations

- Real-time vision inspection and barcode scanning for product validation

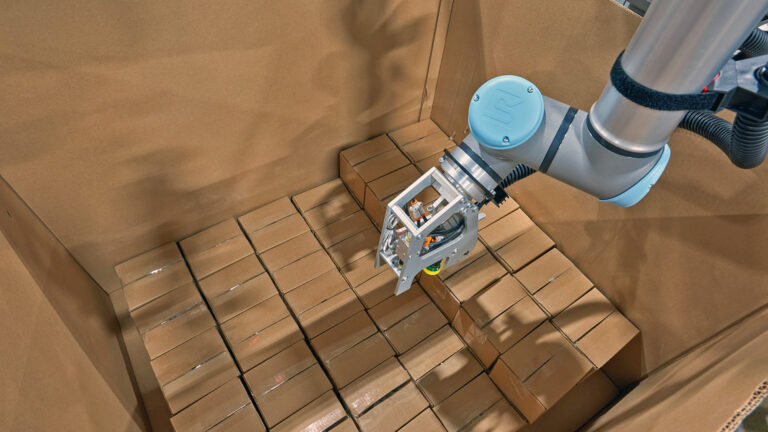

- Vacuum-driven palletizing cobots loading packed boxes into a large-format Gaylord

- Compact, forklift-movable cell requiring only basic utilities and HMI recipe selection Packaging Strategies+15Midwest Engineered Systems+15Midwest Engineered Systems+15Midwest Engineered Systems+2Midwest Engineered Systems+2

This solution automates both case packing and pallet stacking in a small footprint—with cobot collaboration enabling safe and flexible operation.

Summary: This high-precision dual-cobot cell combines retail packaging and palletizing, delivering a compact, scalable solution with minimal operator oversight.

The Results

Efficient Operation, Improved Workforce Allocation & High Throughput Rates

The turnkey automation delivered immediate production and labor improvements:

- Achieved 56-second cycle per part (≈ 64 packs/hour) YouTube+3Midwest Engineered Systems+3Midwest Engineered Systems+3Midwest Engineered Systems

- Eliminated manual packing and palletization labor—operators now support other value-added tasks

- Supported multiple case styles and product types consistently via HMI recipe control

- Improved accuracy and ergonomics using collaborative robot automation

By integrating packaging and palletizing in one seamless robot cell, MWES enabled faster output, higher accuracy, and reduced labor dependence—while maintaining flexibility for part mix changes.