The Challenge

Eliminating Manually Intensive Pallet Breakdowns in a High-Volume DC

Distribution center operators were overwhelmed by manual unloading of stacked cases from pallets. With labor shortages and high throughput expectations, the facility needed automation to:

- Extract full layers of cases—regardless of case dimensions or pallet configuration

- Handle up to 540 lb layers measuring 54″ × 54″

- Feed downstream conveyors with consistently oriented cases

- Maintain high throughput amid fluctuating incoming shipments

MWES was selected to design and integrate a flexible, high-capacity depalletizing solution tailored to the customer’s dynamic logistics needs.

The Solution

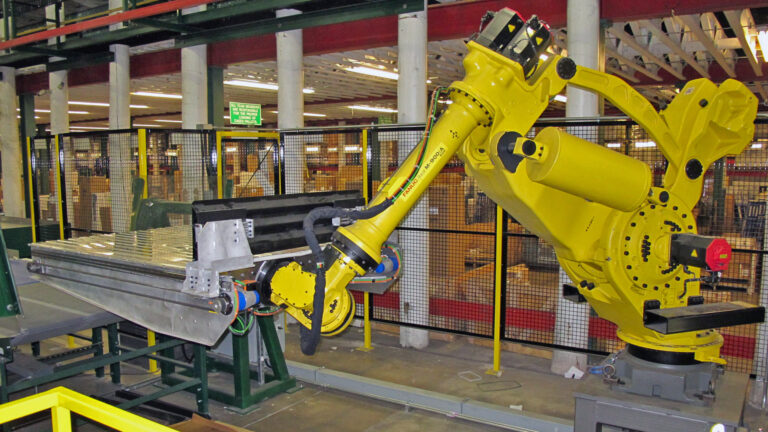

Layer-Gripper Depalletizer & Descrambler Cell with Layer Loading & Conveyor Integration

MWES delivered a turnkey automation system that uses a Schmalz vacuum layer depalletizer and custom Descrambling EOAT:

- Picks entire layers from full pallets—using vacuum-equipped layer gripper capable of handling 540 lb loads

- Transfers layers to an outfeed descrambling conveyor for de-stacking and case sorting

- Accommodates varying case sizes and pallet patterns with recipe-driven robot logic

- Integrates seamlessly with existing conveyor infrastructure and DC workflows

This solution enabled high-speed, hands-free handling of incoming pallets, preparing mixed-size cases for consistent downstream flow with minimal operator involvement.

The Results

High-Throughput, Reduced Labor & Reliable Continuous Operation

The MWES system delivered strong operational gains:

- Achieved an average layer pick rate of one layer per 15 seconds (≈ 4 layers per minute)

- Eliminated manual pallet breakdown labor in depalletizing operations

- Improved throughput consistency and reduced labor burden

- Scalable solution deployed across multiple distribution centers

By automating a traditionally labor-intensive and inconsistent process, the customer dramatically improved distribution center efficiency while reducing safety risks and labor demands.