The Challenge

Manually Loading Heavy, Random Parts into Heat-Treat Systems

The customer faced a hazardous, labor-intensive workflow logging parts manually from multiple bins into a heat-treat operation. Goals included:

- Automating part retrieval from disorganized bins

- Identifying and orienting mixed metal part types automatically

- Safely handling sharp and heavy components

- Improving throughput and bypassing labor shortages

MWES was chosen to design a vision‑guided robotic solution capable of handling heavy, random parts with precision and safety.

The Solution

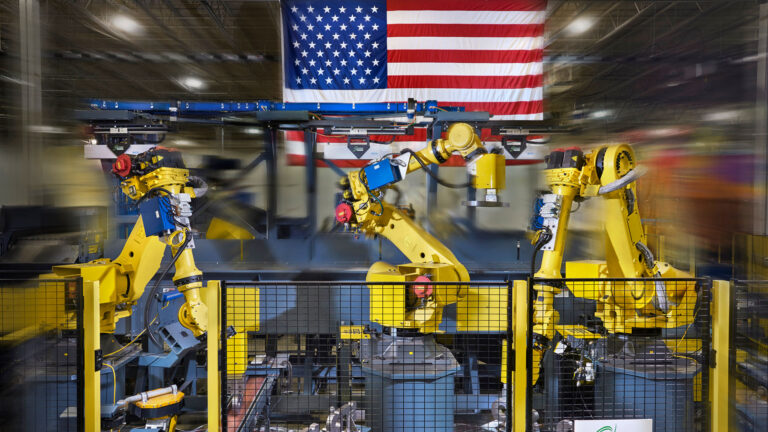

3-Robot PLB Vision-Guided System with Bin Conveyor Feeding

MWES engineered a system integrating 3D vision with Fanuc robots, conveyors, and RFID-controlled workflows:

- CDLR conveyors deliver full bins and automatically loop empty bins out of the pick station

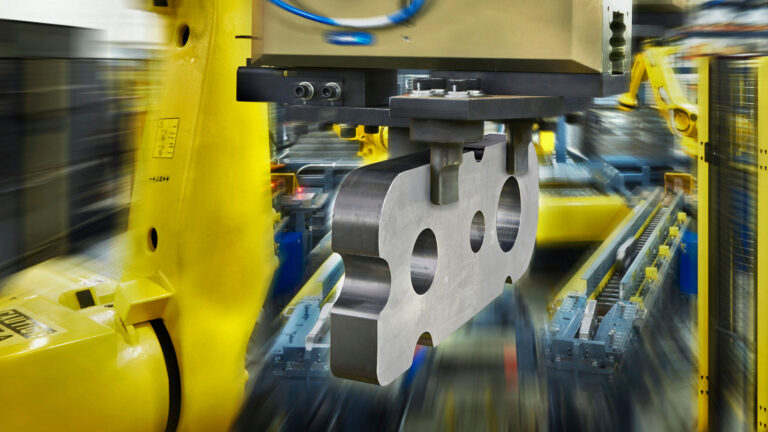

- Three Fanuc robots with magnetic EOATs pick parts and reposition them for conveyor loading

- SICK PLB 3D vision sensors identify part orientation and determine optimal pick points

- Secondary pick station optimizes sample orientation for downstream placement

- Cell controller (ControlLogix + Oracle transaction manager) manages part recipes, tracking, and cell coordination

This holistic system autonomously pulls parts from bins and feeds them into the heat treat line—minimizing manual labor and complexity.

The Results

Increased Throughput, Reduced Risk & Fast ROI

MWES delivered significant operational benefits for the customer through automation:

- Achieved ≤ 1 part every 6 seconds loading rate

- Increased productivity by 10–20% over manual operation vision-systems.com+10roboticstomorrow.com+10manufacturingtomorrow.com+10mwes2018.wixsite.com

- Eliminated worker exposure to hot, sharp parts and repetitive motion

- System achieved ROI in under 2 years

- Consistent part handling with zero part-number or debris errors

By combining advanced vision with robotic automation, MWES helped the customer enhance safety, throughput, and process reliability.