The Challenge

Achieving Pharma-Level Cleaning & Coating Speed Without Sacrificing Cleanliness

The customer needed fast, repeatable processing of injection-molded components to stringent pharmaceutical standards, while minimizing contamination risk and maximizing output. Their needs included:

- High-speed washing and coating of plastic vials and cartridges

- Precise interior and exterior cleaning via multi-jet systems

- Consistent, closed-loop curing of commercial coating agents

- Compact footprints, cleanroom-grade enclosure, and traceable cycle times

MWES was selected for its ability to design cleanroom automation systems with tight cycle control and durable part cleanliness.

The Solution

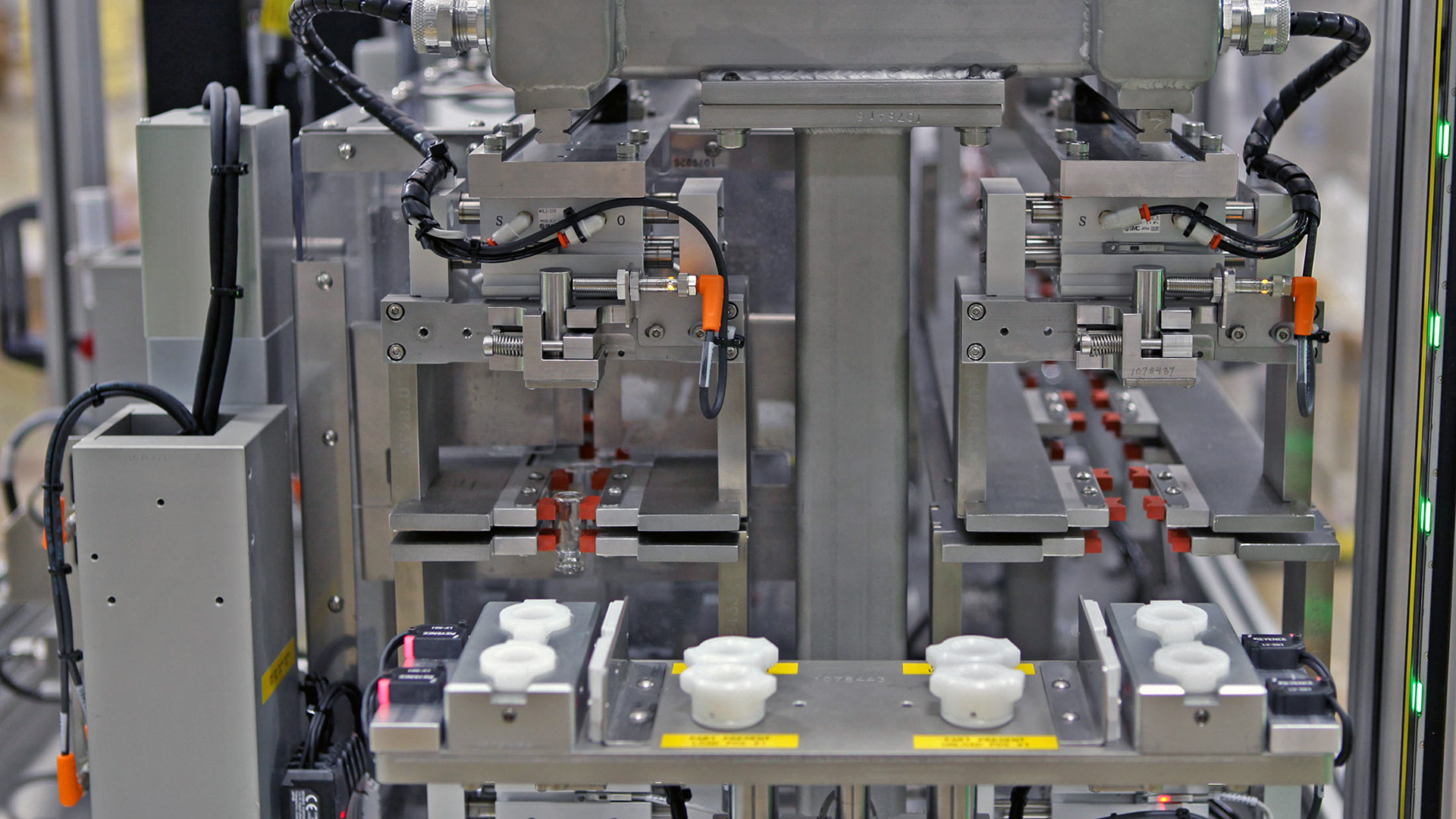

Five-Stage Cleanroom Cell with Wash, Dry, Coat & Cure Functionality

MWES engineered a sealed automation cell that integrates sequential processing steps within an ISO‐rated enclosure:

- Exterior and interior high-pressure water jets for deep cleaning

- Dual-stage forced-air drying (external and internal) to eliminate residual moisture

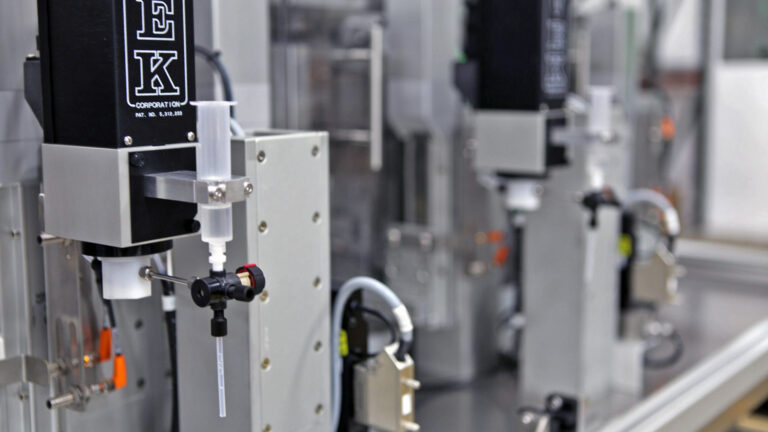

- Proprietary coating spray module to uniformly apply treatment agent

- Curing stage with controlled temperature management via closed-loop feedback

- Positive-pressure cleanroom enclosure for contamination protection and compact footprint (< 10 ft wide)

The highly integrated design combines precision cleaning and coating flow with environmental controls to meet clean processing standards.

The Results

12-Second Cycle Time per Part, High Repeatability & Cleanroom Compliance

Post-installation benefits include:

- Consistent processing cycle of approximately 12 seconds per part

- Reduced contamination risk via fully enclosed and pressurized cell

- Improved coating uniformity and drying consistency across runs

- Minimized manual steps, maintaining operating benefits in clean-room environment

By automating the full component preparation and coating process, MWES helped the customer boost throughput, achieve medical-grade cleanliness, and deliver repeatable part quality—without operator-dependent variability.