The Challenge

High Product Variety Strained Manual Assembly Capabilities

A manufacturer producing numerous hydraulic motor configurations needed a flexible assembly approach that could adapt to frequent part variation without sacrificing throughput or quality.

- Over a dozen hydraulic motor variants handled in a single line

- Manual switching between configurations increased operator errors

- Lack of in-process tracking made quality and progress monitoring difficult

- Existing process could not scale efficiently with demand

MWES was tasked with creating a manual assembly system capable of varying workflows, maintaining consistent quality, and accommodating future operational needs.

The Solution

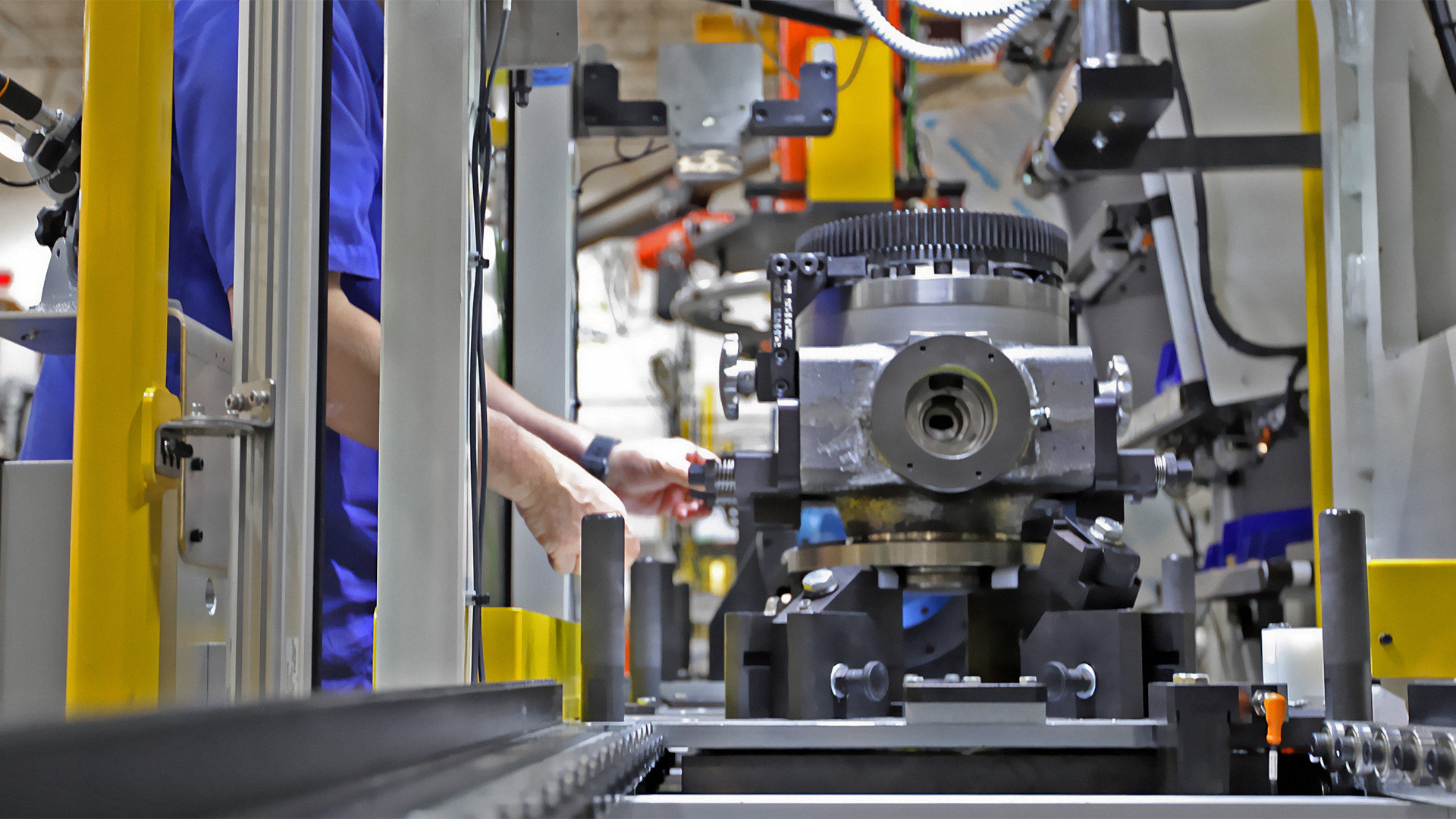

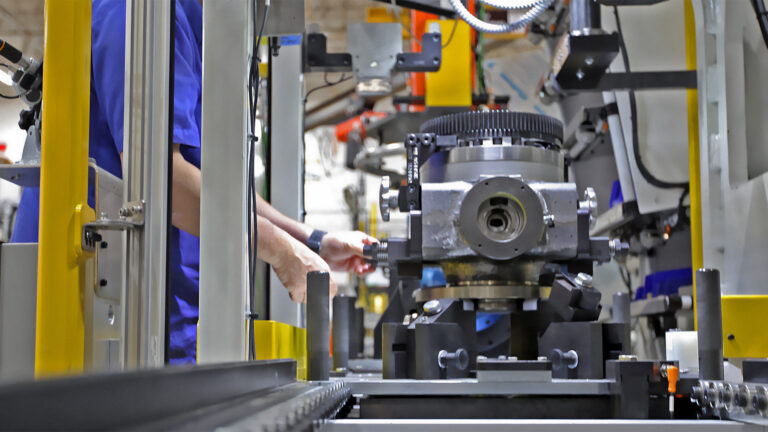

Vision-Guided Manual Assembly with Variant-Specific Workflow Integration

MWES designed a modular manual assembly line featuring dedicated subassembly stations, integrated vision-based tracking, and flexible operator choreography.

- Discrete workstations adapt workflow per motor variant

- Vision inspection monitors assembly progress and tooling accuracy

- Station logic guides operators through variant-specific steps

- Buffering and routing manage part flow efficiently

The organized cell layout, combined with automation-grade controls, delivered a structured manual process that scales across product variants.

The Results

Process Flexibility, Quality Control & Scalable Throughput

The resulting system successfully handled high mix without automation, improving assembly reliability and throughput consistency.

- Supported assembly of 12+ motor variants on one production line

- Enhanced quality control through vision-based monitoring systems

- Reduced operator errors and assembly variability

- Enabled scalable assembly throughput aligned with product demand

MWES helped the customer retain manual capabilities while securing the flexibility and consistency typically associated with robotic systems—ideal for high-mix, low-volume production.