The Challenge

Manual Die-Cast Machine Tending Was Inefficient and Risky

The customer needed to significantly reduce manual operator involvement in dangerous, repetitive processes. Their objectives included:

- Eliminating manual extraction of hot castings from die-casting machines

- Automating part transfer into a trim press when required

- Achieving a rapid cycle time to maintain production flow

- Improving scrap recovery and error handling

They required an automation partner that could deliver a safe, high-speed solution to tend the die-cast process with minimal operator oversight.

The Solution

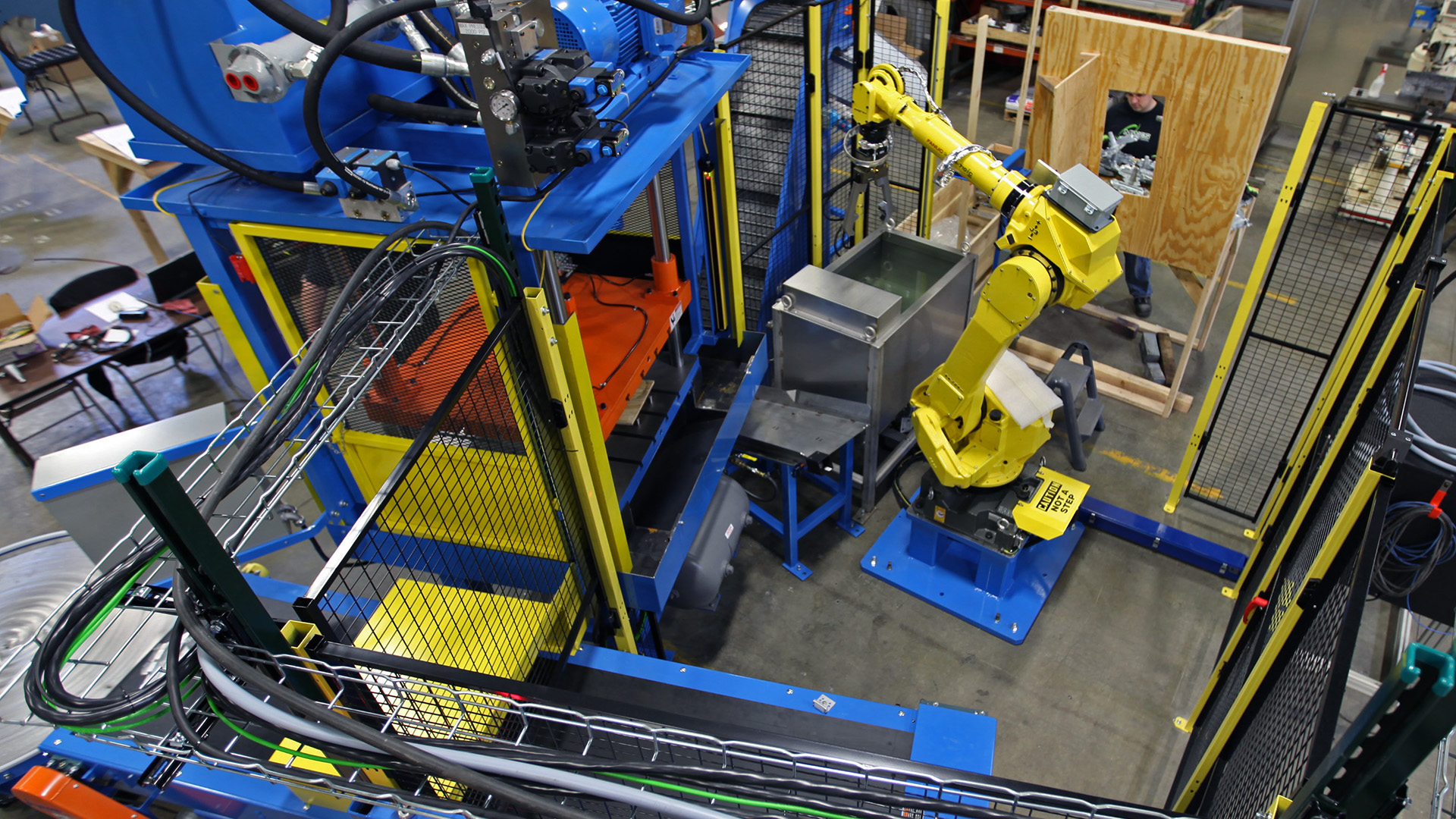

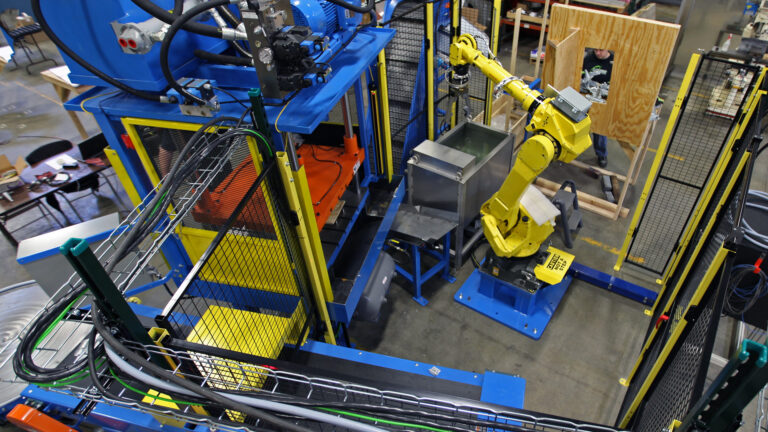

Robotic Tending Cell with Integrated Quench and Trim Operations

MWES provided a fully integrated machine tending system that included:

- Fanuc M-710iC/50 robot with R-30iB Mate controller and pneumatic EOAT

- Part verification stand to confirm successful pickup before processing

- Dunk quench tank with heat exchanger and pump for rapid part cooling

- Motorized turntable for part accumulation and operator buffer time

- Trim press integration for automatic post-cast part trimming

- Outfeed cooling conveyor and scrap chute system for part sorting

- ANSI/RIA R15.06-2012-compliant safety systems including guarding, interlocks, stack light, and E-stop

- Allen-Bradley CompactLogix PLC with touchscreen HMI and complete I/O controls

The robot extracts freshly cast parts, checks pick validity, quenches them, and optionally transfers them to a trim press—all while minimizing manual intervention. Rejected parts are segregated automatically.

The Results

High-Speed, Safe Tending with Improved Yield and Labor Efficiency

The MWES robot die-cast tending system delivered substantial value across multiple areas:

- Achieved sub-18 second part-to-part cycle time

- Reduced operator exposure to hot metal and repetitive tasks

- Improved scrap recovery and error handling via automated rejection routing

- Enhanced maintainability and uptime with smart monitoring

- Reduced floorspace requirements with compact design and part buffering

This robotic tending system helped the customer reduce labor, increase consistency, and lower risk, yielding strong ROI and scalable production capacity.