The Challenge

Replacing Skilled Labor in CNC Lathe Operations

A global fluid fittings manufacturer sought to automate a traditionally manual CNC turning process to:

- Eliminate dependence on highly skilled operators

- Streamline long-duration machining cycles with minimal human oversight

- Maintain consistent part quality across large production runs

- Reduce labor bottlenecks in lathe tending operations

MWES was selected to provide a turnkey robotic system that could integrate seamlessly with existing CNC equipment and improve operational efficiency.

The Solution

Robot-Integrated CNC Tending with Vision-Guided Loading

MWES engineered a system to automate the full CNC turning workflow:

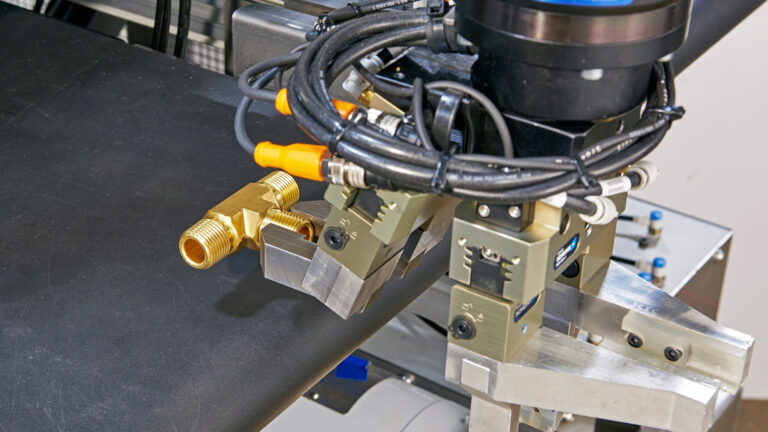

- Fanuc-based robot loads raw parts from an infeed conveyor into the Okuma lathe

- Vision-guided system ensures accurate part orientation and placement

- Operator inputs the program via HMI and initiates cycle start

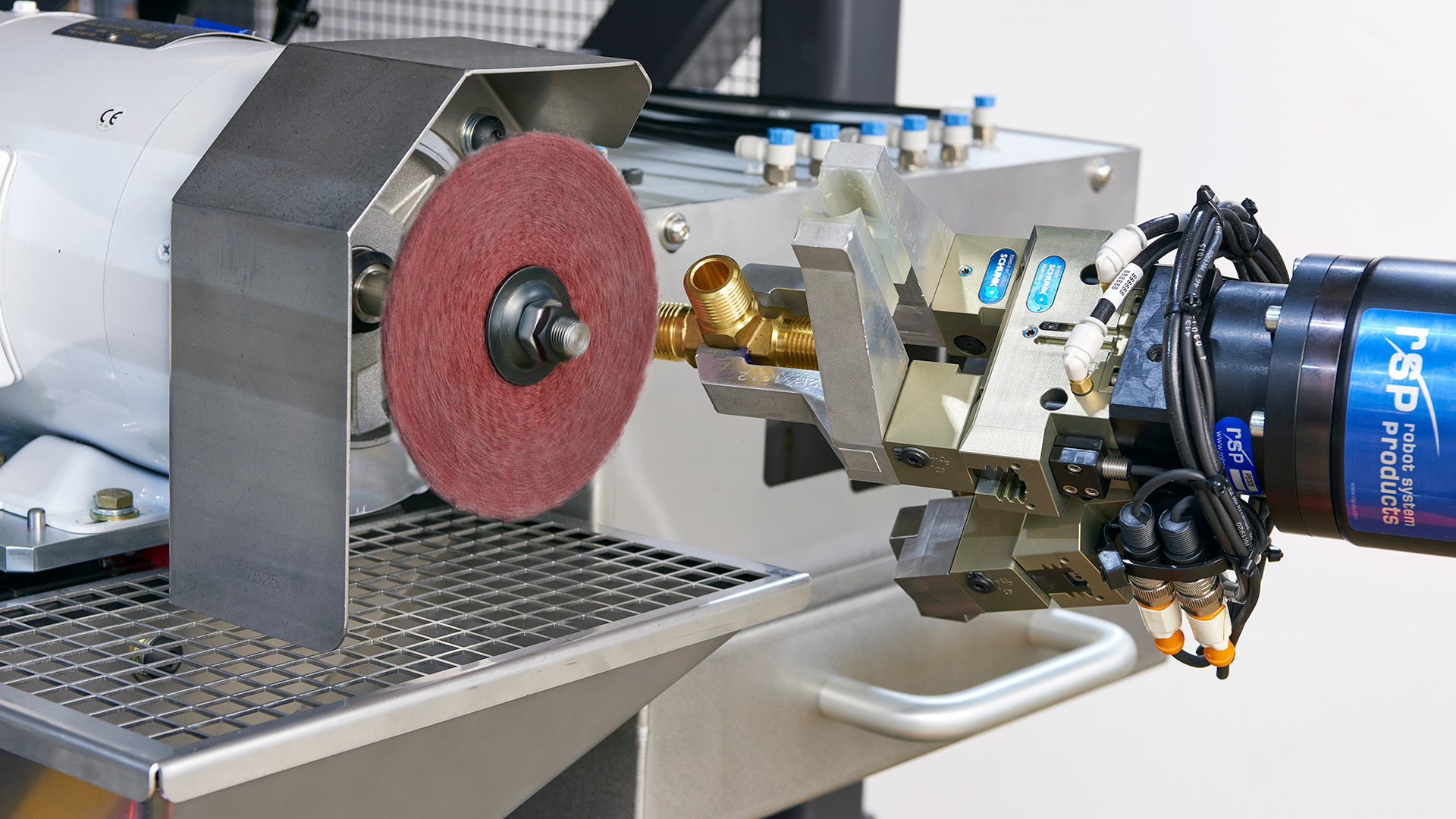

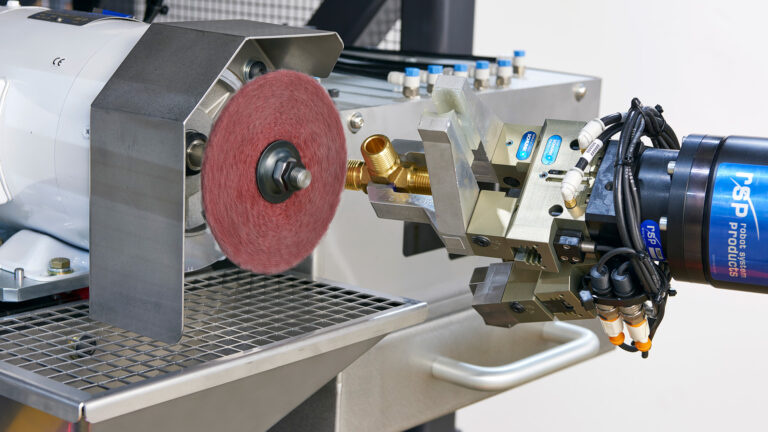

- Robot retrieves finished parts, then routes them through debris blow-off and a deburring station

- Clean parts are placed on the outfeed conveyor for final handling

This turnkey system handles the full machine tending cycle—from load to load—with minimal operator intervention and high repeatability.

The Results

Higher Throughput, Lower Labor, and Better Consistency

MWES’s automatic CNC tending solution delivered measurable operational gains:

- Reduced reliance on skilled labor by automating tool loading and part handling

- Improved cycle efficiency and throughput for long-running machining jobs

- Enabled one operator to oversee high-mix production without direct lathe work

- Enhanced part cleanliness and quality consistency via automated cleaning and deburring

This solution helped the customer boost machining capacity while lowering staffing demands and improving process reliability.