The Challenge

Manual Slicing and Stacking Was Inconsistent and Slowed Production

Staff struggled to maintain consistent stack counts and quality during continuous slicing operations. Goals included:

- Automating slicing of consistent-sized cheese sticks at scale

- Grouping sticks into uniform stacks for packaging

- Synchronizing slicing speed with stacking and downstream processes

- Maintaining sanitation standards and minimizing operator touchpoints

MWES was selected to provide a hygienic, high-speed automation solution capable of handling continuous slicing and stacking with precision and cleanliness. (mwes.com)

The Solution

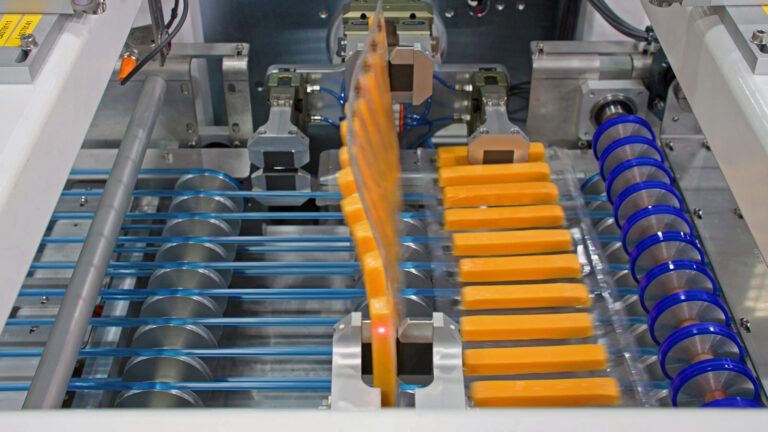

Vision-Guided Slicing & Stacking System with Custom Conveyor Integration

MWES engineered a complete slicing and stacking system with:

- Automated slicers aligned to cut cheese logs into precise sticks

- Vision-guided conveyor and pusher arms to stack slices in set sizes

- Integrated Omega 9-grit belt conveyors to move stacks downstream

- Motion syncing between slicing, stacking, and outbound flow

- Sanitary design compliant with USDA and FDA food processing standards

This turnkey solution handles full slicing-to-stacking automation, ensuring hygienic, continuous flow from processing to packaging staging.

In summary, the system carefully coordinates slicing and stacking with integrated vision and conveyor control—delivering seamless, food-grade automation.

The Results

High-Speed, Accurate Stacking with Reduced Labor and Better Throughput

MWES’s solution produced measurable benefits in hygiene, efficiency, and performance:

- Achieved stacking speeds up to 100 sticks per stack in under 2 seconds per stack

- Maintained consistent stack counts and orientation for accurate packaging

- Eliminated repetitive manual handling and stacking tasks

- Improved sanitary compliance and reduced operator contact with food product

By automating the slicing and stacking process, MWES enabled the customer to boost throughput, improve stack consistency, and maintain hygienic operations—all while reducing direct labor involvement and variability.