The Challenge

Custom Robotic Depalletizing Cell Integrated into Existing Brewery Operations

Widmer Brothers Brewing bottle depalletizing process was historically handled manually by production staff. Workers lifted shrink-wrapped pallets, removed bottles, and staged them for conveyor feed into rinsing, filling, and packaging equipment. This approach presented multiple challenges:

- Ergonomic and Safety Risks: Repetitive lifting, bending, and handling of bottles increased the potential for strain and injury.

- Inconsistent Feed Rates: Manual operations created variability in bottle flow to downstream processes, sometimes causing bottlenecks at rinsing and filling stations.

- Labor Strain: With production demands increasing, manual depalletizing was consuming valuable labor resources that could be better utilized elsewhere.

- Maintenance of Quality & Pace: The brewery needed a solution that could maintain product quality and consistent throughput without requiring extensive staff hours.

Widmer Brothers Brewing sought a depalletizing automation solution that would work with existing infrastructure, improve safety, and deliver reliable performance without disrupting the rest of the production line.

The Solution

Custom Robotic Depalletizing Cell Integrated into Existing Brewery Operations

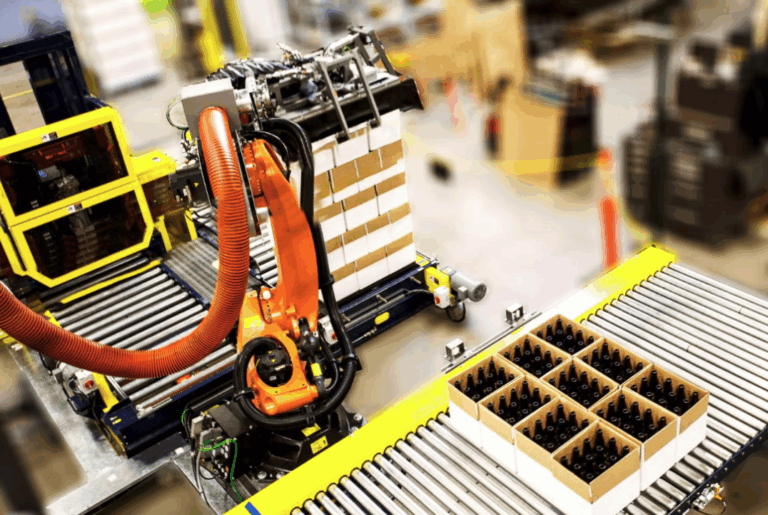

MWES designed and implemented a robotic depalletizing cell specifically tailored to Widmer Brothers Brewing production requirements. The system uses a high-payload industrial robot equipped with specialized End-of-Arm Tooling (EOAT) optimized for handling bottles of various sizes and configurations.

Key features of the solution include:

- Robotic Pallet Unloading: A single industrial robot equipped with custom suction-based EOAT gently and reliably lifts bottles off pallets without damage.

- EOAT Designed for Bottle Handling: Custom tooling accommodates different diameters and packaging formats, enabling consistent grips and stable handling.

- Pallet Indexing & Stabilization: Pallet handling mechanisms secure shrink-wrapped loads for safe and predictable depalletizing.

- Seamless Conveyor Integration: Bottles are deposited onto the brewery’s existing conveyor system in a controlled, consistent manner, matching the pace of downstream rinsing and filling.

- Robust Safety Systems: Light curtains, guarded zones, and interlocks ensure operator safety around the depalletizing cell.

Once a bottle pallet is presented to the robot cell, the system automatically removes bottles from the pallet layer by layer and feeds them onto the conveyor, maintaining a smooth production flow with minimal human intervention.

The Results

Improved Throughput, Safer Operations, and Reduced Labor Dependence

Implementation of the robotic depalletizing automation delivered significant operational benefits for Widmer Brothers Brewing:

- Improved Throughput: Automated bottle handling eliminated the variability of manual depalletizing, delivering a consistent feed rate that matched downstream processing requirements.

- Enhanced Worker Safety: Repetitive lifting and manual handling were removed from the operator workflow, reducing ergonomic strain and the risk of injury.

- Reduced Labor Dependency: The robotic cell replaced what had been multiple hours of manual labor per shift, freeing staff to focus on higher-value production tasks.

- Seamless Line Integration: The system integrated with the brewery’s existing conveyor and process flow, minimizing installation disruption and preserving footprint.

- Reliable, Repeatable Performance: The automation cell operates without fatigue, delivering dependable performance even during high-volume production runs.