The Challenge

Manual Loading of Heavy, Repetitive Parts into Steel Baskets

The customer’s heat-treat process required operators to manually handle and position parts into steel baskets for transfer into ovens. Key challenges included:

- Labor-intensive loading and unloading of baskets

- Multiple part types requiring specific orientation

- Consistent, accurate placement for optimal heat-treat results

- Risk of repetitive strain injuries and handling inefficiencies

MWES was tasked with delivering a robotic solution to automate the full load/unload cycle for multiple part SKUs.

The Solution

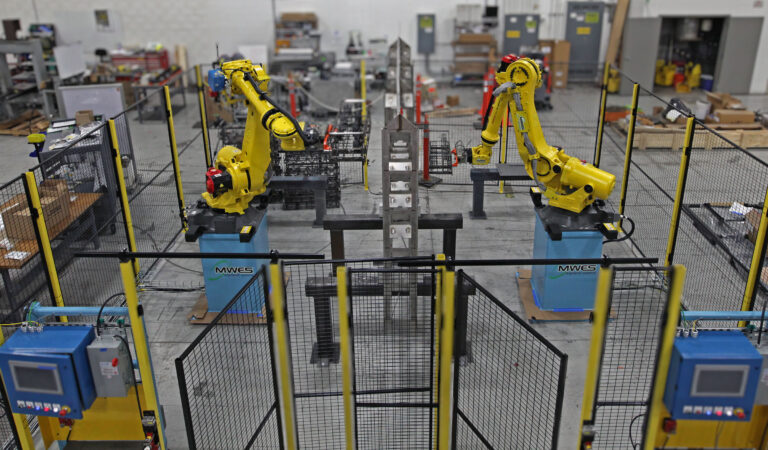

Fanuc Robot System with Custom Tooling and Basket Fixtures

MWES developed a fully automated robotic system integrating:

- A Fanuc M-900iA/260L robot for high-payload part handling

- Custom EOAT with dual gripper design for efficient part pickup and placement

- Modular basket fixturing to accommodate multiple part types and orientations

- Integrated vision guidance for accurate part location and orientation

- Seamless integration with existing conveyor and furnace systems

The robot picks parts from an inbound conveyor, places them precisely into baskets, and performs the reverse motion to unload post-processed parts—ensuring consistent and efficient material flow.

The Results

Reduced Labor, Improved Consistency, and Faster Cycle Times

MWES helped the customer realize substantial benefits through automation:

- Eliminated manual loading of heavy parts, improving operator safety

- Achieved consistent placement of parts for reliable heat treatment

- Reduced cycle time and increased overall system throughput

- Flexibility to handle multiple part types with minimal changeover

- Improved uptime and efficiency in a demanding industrial environment

This solution delivered the speed, safety, and repeatability the customer needed—proving that robotic handling is a smart investment for demanding thermal processing lines.