The Challenge

Speed and Efficiency in Repetitive, Labor-Intensive De‑Stacking

The customer’s manual de-stacking process slowed production and relied heavily on labor. Their automation objectives included:

- Handling large oven cart plates in tight succession

- Reducing cycle time to under 90 seconds per de-stack

- Minimizing worker involvement for high-throughput shifts

- Maintaining precision in separating stacked plates

MWES was commissioned to design a robotic system that could de-stack, separate, and feed plates reliably—ensuring faster throughput and reduced labor strain.

The Solution

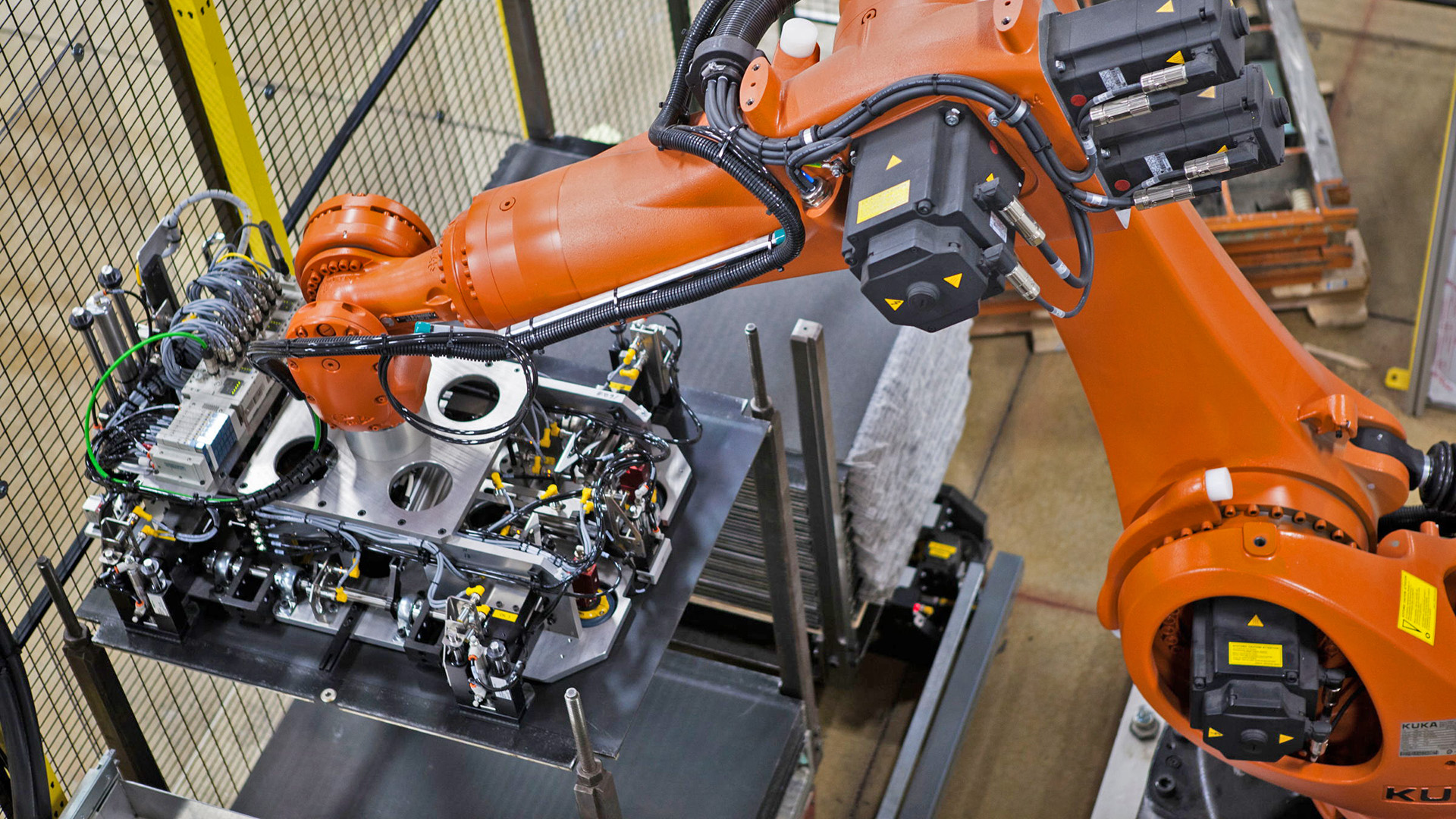

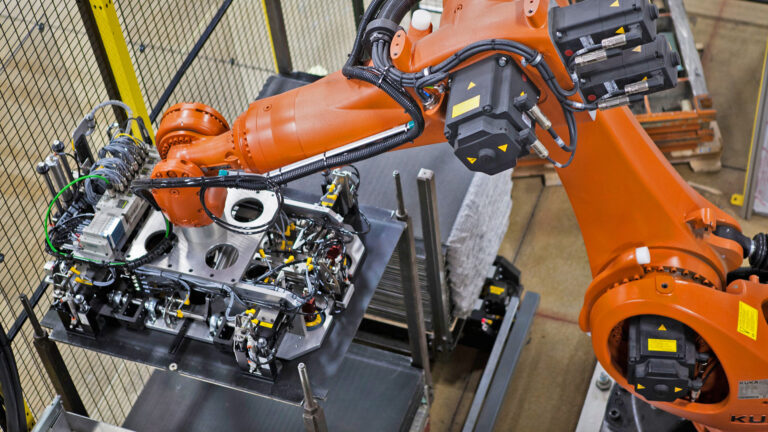

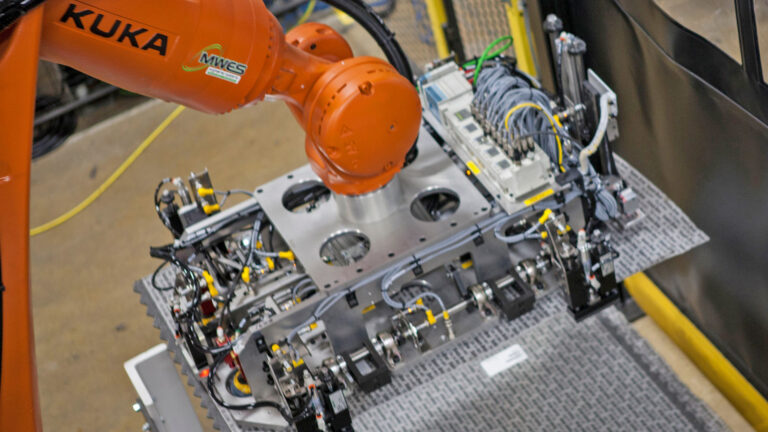

Robotic De-Stacking Cell with Vacuum Layer Pickup and Automation Flow

MWES developed a system that automates entire plate separation and handling using robotic control and vacuum EOAT technology:

- Vacuum-based layer pickup to lift entire plate sets at once

- Industrial robot positions plates onto downstream processing conveyors

- Integrated control system sequences de-stacking, separation, and flow logic

- Design enables <90-second cycle times with robust repeatability

This turnkey system ensures smooth, continuous material handling from stacked plate load to downstream operations.

The Results

Faster Throughput, Lower Labor, and High Repeatability

MWES delivered measurable improvements in process flow and operating efficiency:

- De-stack operations completed in less than 90 seconds per cycle

- Minimizes operator intervention during the process

- Supports continuous, automated material feed for downstream ovens

- Reduced manual labor burden and improved production consistency

This automation cell helped the manufacturer achieve higher throughput and decreased reliance on shift labor for repetitive plate handling.