The Challenge

High-Speed Water Outlet Assembly With Error-Free Leak Testing

Manual part handling and inspection introduced inefficiencies and variability into the production process. The customer needed a robust automated solution to::

- Maintain consistent quality at high production volumes

- Automate spin weld assembly and limiter installation

- Perform real-time leak detection and visual inspection

- Automatically sort failed parts and pack good parts efficiently

MWES was chosen for its expertise in high-speed robotic automation for injection-molded components and precision assembly environments.

The Solution

Integrated Robotic Cell for Assembly, Testing, and Final Packing

MWES engineered a fully automated robotic system that combines part handling, welding, inspection, leak testing, and packing into a continuous, hands-free line.

- Fanuc M710ic/20L robot with dual end-of-arm tooling for part handling and layer packaging

- 2D vision inspection camera to validate degating and post-weld blacklight tests

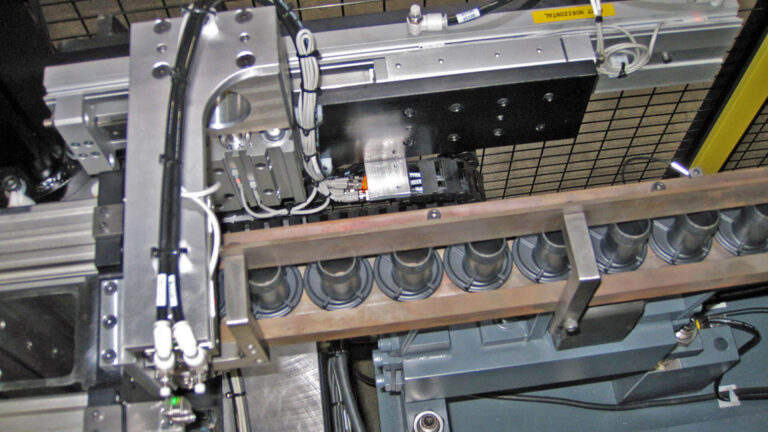

- Spin weld station for assembling housings and inserting limiters

- Pneumatic port-probe system for automated leak detection via shuttle stations

- Automated reject logic: failed parts diverted, good parts stacked and bagged into Gaylords

- Dual-layer box packing with pad separation for part protection

This integrated solution eliminated manual intervention from start to finish, ensuring a reliable and repeatable production process.

The Results

Fully Automated, 25-Second Cycle with Single-Operator Oversight

The automated cell delivered these operational benefits:

- Achieved consistent 25-second cycle time per part, running three shifts per day

- Consolidated full assembly, leak testing, and packing from unassembled parts

- Required only one operator to load parts and monitor system flow

- Improved throughput, reduced defects, and minimized labor costs

By combining robot-driven assembly, integrated inspection, quality testing, and layer-based packing, MWES enabled enabled scalable, high-speed water outlet production with minimal labor involvement and high product reliability.