The Challenge

Automating High-Volume Press Feeding of Heavy HVAC Baffles

Federal baffles and condenser components are heavy and require precise alignment for pressing. The customer needed automation to:

- Load large, cold-formed baffles into a hydraulic press reliably

- Maintain throughput for high-volume HVAC production

- Eliminate manual lifting, alignment, and positioning variability

- Seamlessly integrate robotic motion with press sequencing

MWES was selected for their experience integrating robots into machine-centric manufacturing systems in HVAC and sheet metal applications.

The Solution

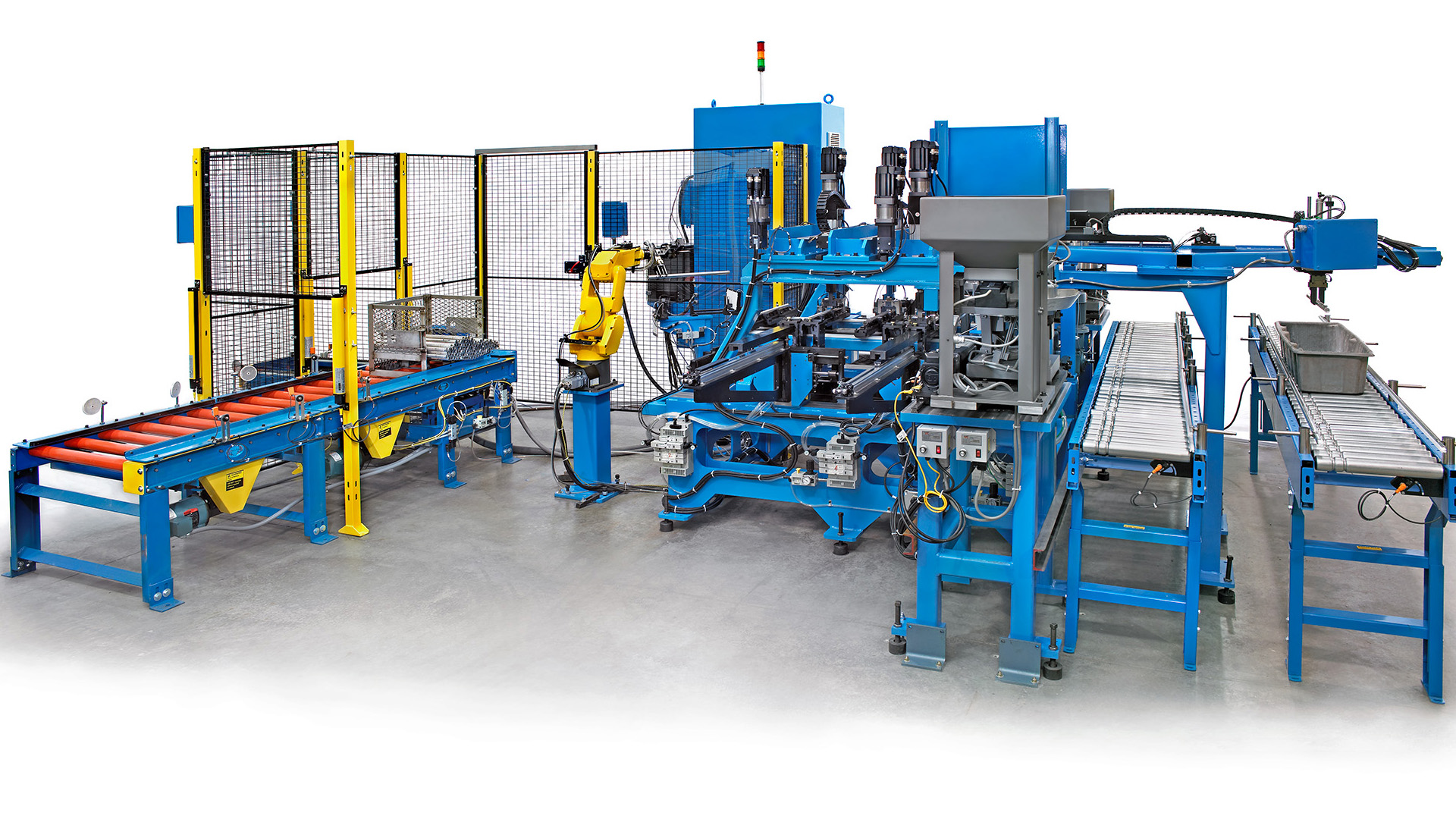

Robot-Loaded Press Cell with Vision & Tooling Integration

MWES delivered a complete automation cell including:

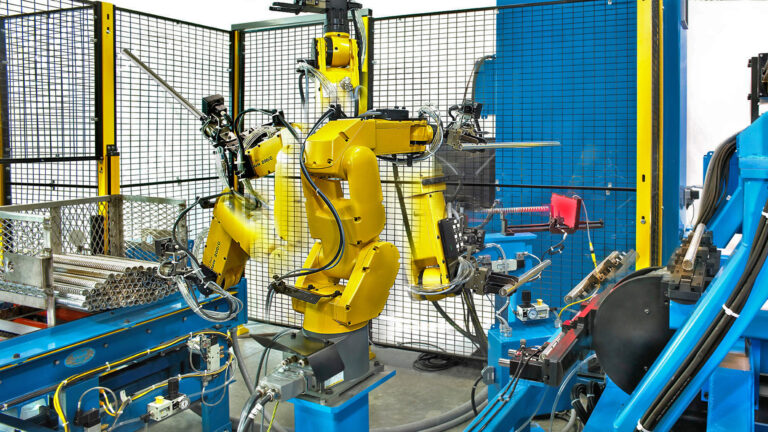

- Industrial robot programmed to pick and orient baffle parts from staging racks

- Custom end-of-arm tooling designed for stable handling of steel baffles

- Sequenced robot motion synchronized with press closing cycle

- Vision or sensor feedback for part alignment and quality confirmation

- Safety interlocked cell design with integrated operator controls

This robotically-loaded press cell automates previously manual tasks—from part lifting and orientation to final pressing—delivering reliable cycles with operator safety.

The Results

Increased Throughput, Reduced Labor, and Consistent Forming Quality

The implemented system provided measurable benefits:

- Continues high-rate press feeding with zero manual lifting

- Increased forming consistency and reduced scrap from misfeeds

- Reduced operator fatigue and ergonomic risk from handling heavy baffles

- Supported higher production volumes with minimal staffing overhead

By integrating robotic feed handling with press operation, MWES enabled safer and more efficient baffle forming—boosting throughput, consistency, and workforce flexibility.