The Challenge

Manual Stack Bagging Held Back Throughput and Added Labor Burden

Manually loading stacked trays into the bagging machine slowed production and strained workers. The customer needed a system that could:

- Pick up and transfer multiple trays (stacks) at once

- Interface seamlessly with their existing bagging equipment

- Reduce manual handling in a repetitive, labor-intensive task

- Increase packaging throughput without major system overhaul

MWES was selected to deliver a robotic system tailored to automating stack transfers into their existing bagging station while enhancing speed and safety.

The Solution

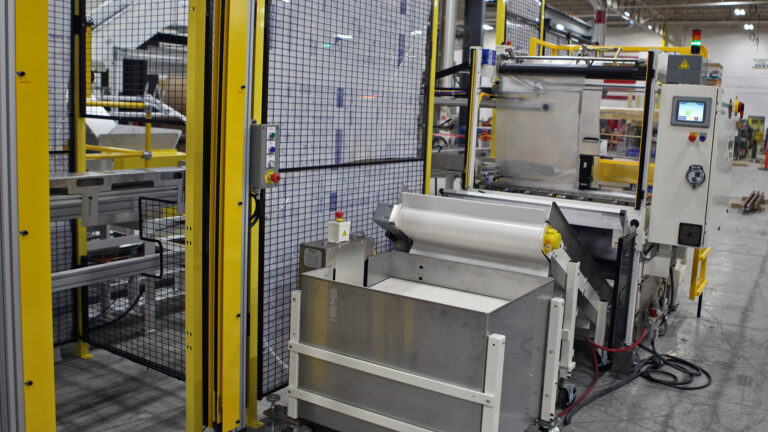

Robotic Stack Transfer Cell Feeding an Automated Bagging System

MWES engineered a turnkey automation cell featuring:

- Robot end-effector capable of gripping and moving four stacked trays at once

- Conveyor with partitioned slots to receive stacks and feed them individually into the bagger

- Timing and sequencing logic synchronized with the bagging equipment

- Operator only needs to load trays and retrieve bagged output

This compact robotic stack-handling cell feeds stacks into the automated bagger seamlessly—eliminating manual transfers while boosting flow through an integrated automation system.

The Results

Higher Bagging Throughput, Reduced Labor & Improved Safety

The implemented automation delivered measurable benefits:

- Eliminated the manual labor of stacking and loading trays into the bagging machine

- Increased bagging throughput by operating synchronously with the bagger

- Improved operational safety by removing repetitive manual handling

- Allowing operators to manage higher-level tasks instead of repetitive transfers

By automating the feed of stacked trays into the bagging system, MWES enabled faster packaging throughput, reduced labor dependency, and improved worker ergonomics—all with minimal system change.