The Challenge

Improving Safety and Speed in Manual Chamfer Operations

The customer’s manual process posed significant safety risks and throughput limitations. Their goals included:

- Reducing operator exposure to sharp, repetitive grinding tasks

- Boosting cycle speed and accuracy during chamfer formation

- Handling multiple part chamfer profiles reliably

- Automating end-to-end flow including inspection and packaging

MWES was selected for its ability to deliver a turnkey robotic chamfer solution that fit within the existing cell footprint and provided precision control over difficult finishing operations.

The Solution

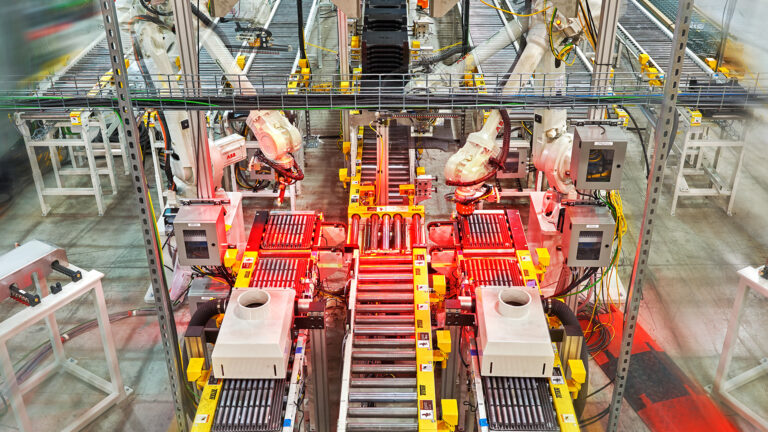

Dual‑Robot Chamfer Cell with Custom Grinders & Laser Inspection

MWES delivered a fully integrated automation cell featuring:

- Two ABB IRB140 robots with self-centering three-jaw grippers

- Four MWES-designed chamfer grinders (2 HP, 3450 RPM) built into a compact layout

- Custom EOAT that rotates parts precisely against the grinding wheels

- Laser inspection station (“Super Sensor”) scanning full part surface post-grind

- Automated reject chute or packaging conveyor based on inspection results

The system processes trays of parts via conveyor or shuttle table, grinding to part-specific chamfer profiles then inspecting and sorting each to reject or package—fully automating the flow.

This end-to-end automation replaces manual part loading, grinding, inspection, and packaging in a single seamless cell.

The Results

Reduced Labor, Safer Operation & Consistent Quality Output

MWES’s solution delivered measurable performance improvements:

- Automated stacking, loading, grinding, inspection, and packaging

- Reduced cycle time by minimizing manual handling and eliminating manual sorting

- Improved operator safety by removing exposure to sharp tools and debris

- Enabled consistent chamfer tolerance and quality with integrated laser inspection

By automating the complete process—from blank presentation to part sorting—MWES helped the customer boost throughput, improve product consistency, and eliminate manual risk.